Novel composite fabric as well as production device and production process thereof

A composite fabric and production process technology, applied in the direction of layered products, textiles, papermaking, fabrics, etc., can solve the problems of easy separation of fabrics, poor hand feeling and discomfort of composite fabrics, and achieve difficult separation, soft hand feeling, breathable and moisture permeability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

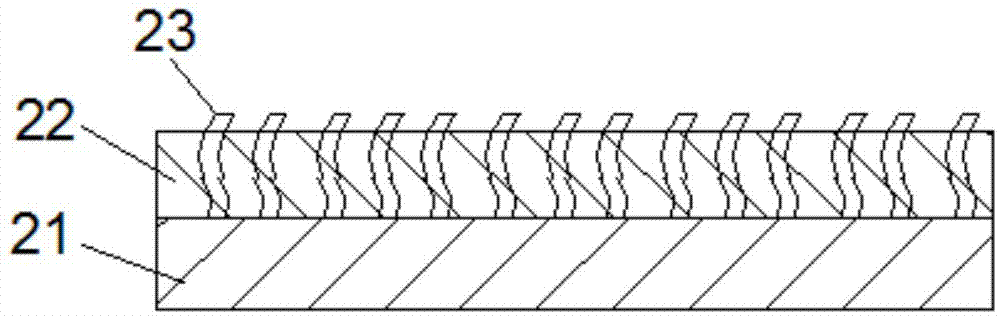

[0024] Such as figure 1 A new type of composite fabric shown includes a bottom fabric 21 and a surface fabric 22, and the fibers 23 on the bottom fabric 21 are pulled into the surface fabric 22 by a high-speed needle plate mechanism, so that the two fabrics are compounded together. Wherein, the surface layer fabric 21 is knitted or woven fabric and is produced from spun yarn or long fiber yarn, and the bottom layer fabric 21 is knitted weft knitted fabric or non-woven fabric and is made of spun yarn yarn or wool blended fibers, the yarn density of the surface layer fabric 22 is greater than the yarn density of the bottom fabric 21.

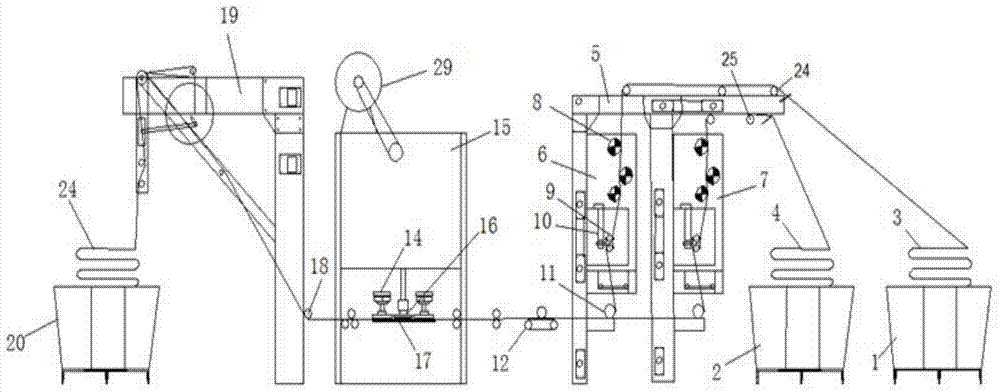

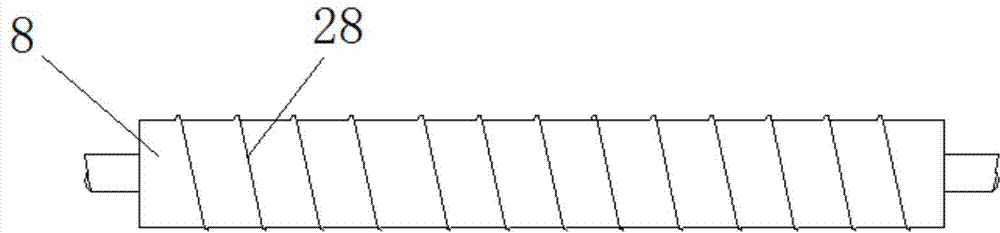

[0025] combine figure 2 and image 3 A kind of production equipment shown, this production equipment is used for producing above-mentioned novel composite fabric, and this production equipment comprises surface fabric cloth groove 1, bottom layer fabric cloth groove 2, front frame 5 and rear frame 19, described Surface fabric cloth groove 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com