Carbon fiber multi-rotor unmanned aircraft fuselage and method for manufacturing the same

A technology of a multi-rotor unmanned aerial vehicle and a manufacturing method, applied in the field of unmanned aerial vehicles, can solve the problems of complex structure, inconvenient use and high cost, and achieve the effects of smooth operation, reduced use cost and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

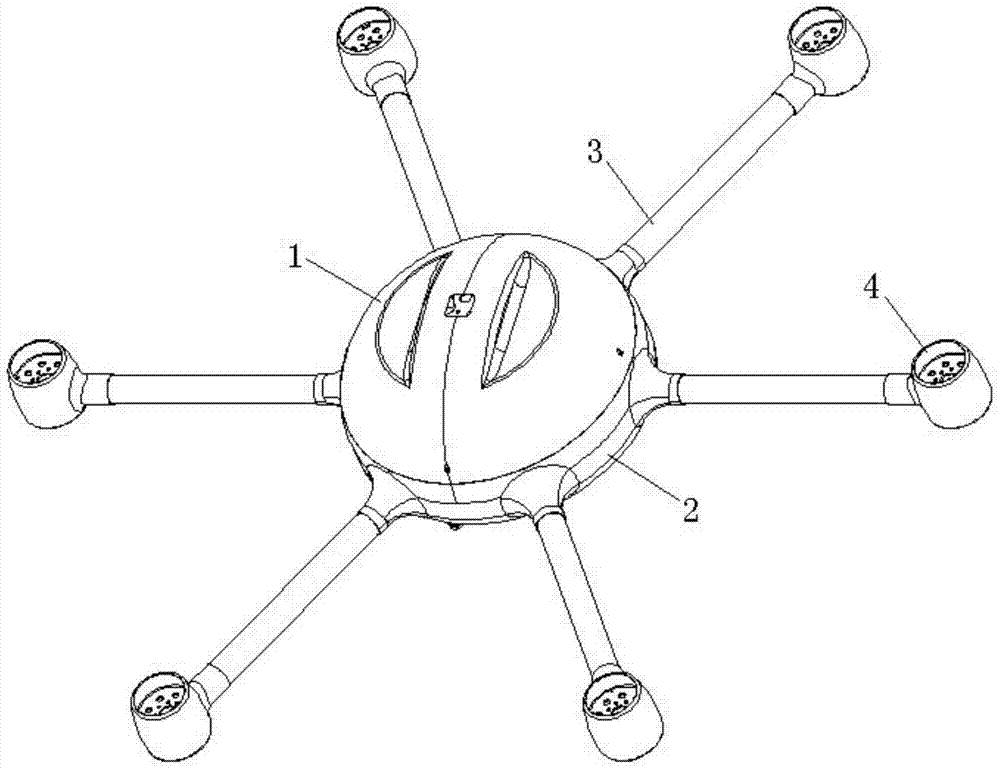

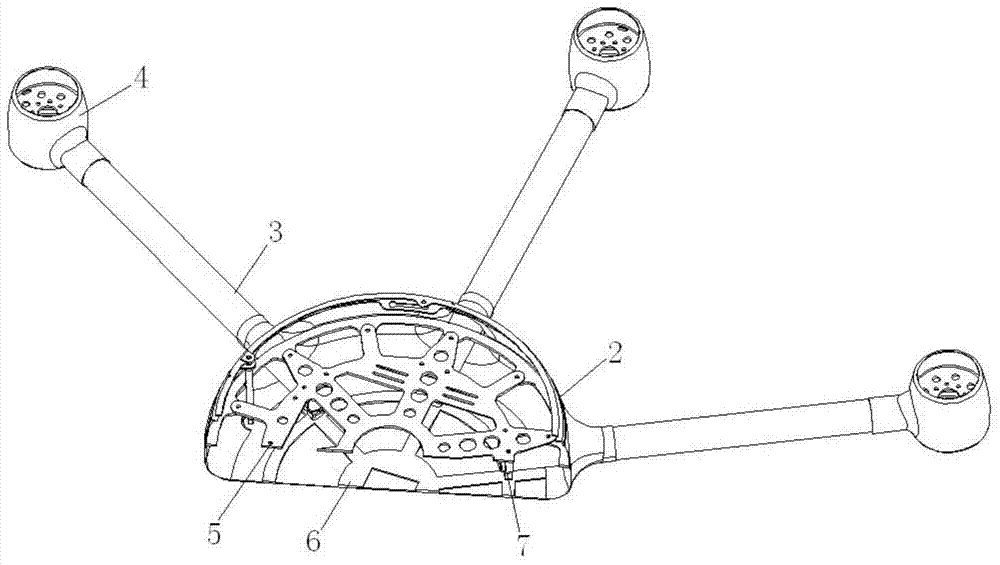

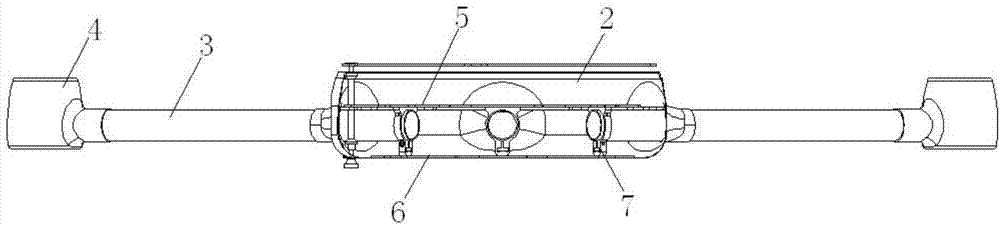

[0042] Such as figure 1 , figure 2 and image 3 As shown, a kind of carbon fiber multi-rotor unmanned aerial vehicle fuselage of the present embodiment comprises central compartment, rotor arm 3 and motor compartment 4, and central compartment comprises central compartment upper cover 1 and central compartment cabin body 2 that are fixed together, The central cabin upper cover 1 and the central cabin body 2 are fixedly connected by bolts 8, specifically, as Figure 6 and Figure 7 As shown, the bolt 8 is a special bolt, one end is processed with an external thread, and the other end is processed with an internal thread. When connecting, one end with an external thread passes through the threaded hole on the central cabin upper cover 1 and the central cabin body 2 to secure the two together; the end with an internal thread passes through the bottom of the central cabin body 2 screw thread connection. In the present embodiment, the middle part of the central cabin body 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com