Mechanical packaging equipment capable of conveying multiple materials

A packaging machinery, multi-material technology, applied in the field of food machinery, can solve problems such as waste of manpower and material resources, low work efficiency, and inability to meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

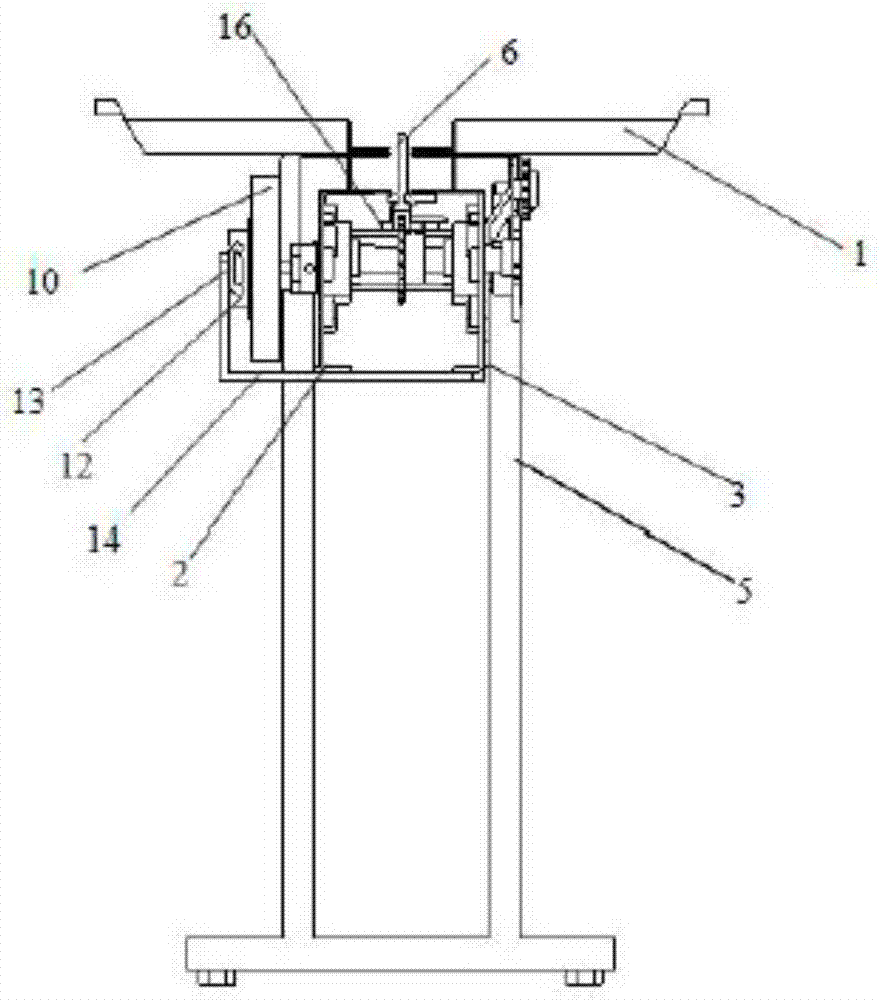

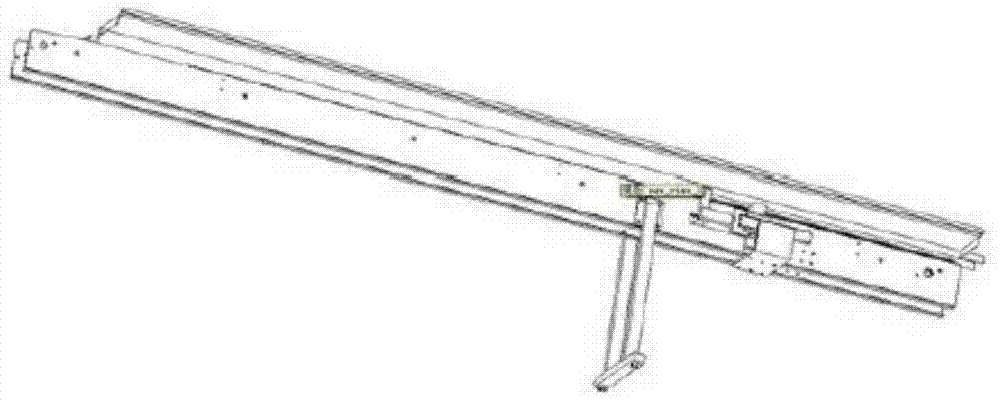

[0009] Such as figure 1 , figure 2 As shown in the figure, a packaging machinery equipment capable of conveying multiple materials includes workbench 1, side panels, and guide rail components. Workbench 1 is divided into left and right workbenches, and side panels are divided into left and right panels. 3. The guide rail assembly includes guide rail A4 and guide rail B. Guide rail A4 is divided into left guide rail and right guide rail. The left and right guide rails are respectively installed on the left and right side panels. Shift fork 6; said pitch shift fork 6 is divided into pitch shift fork A and pitch shift fork B, and pitch shift fork A and pitch shift fork B are longitudinally kept on a straight line; said left and right workbenches Symmetrically installed on the left and right guide rails; there is a pumping plate under the workbench, and the pumping plate is divided into pumping plate A7 and pumping plate B8, which are respectively installed under the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com