Hook arm garbage can

A garbage bin and hook arm technology, which is applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of inconvenient hoisting and transfer, secondary environmental pollution, and the appearance of garbage bins is not beautiful enough, so as to achieve a beautiful appearance design, sealing good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

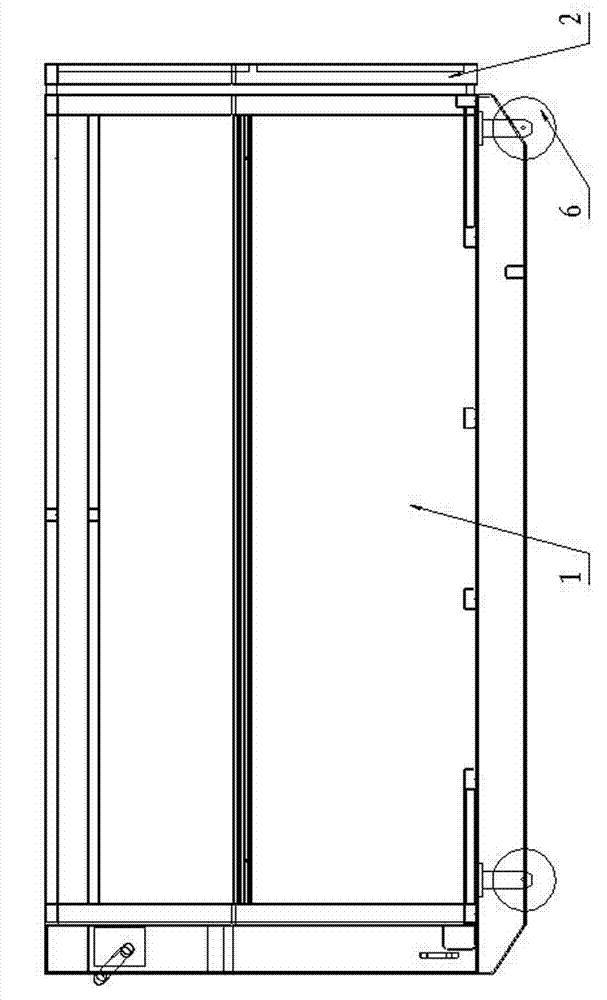

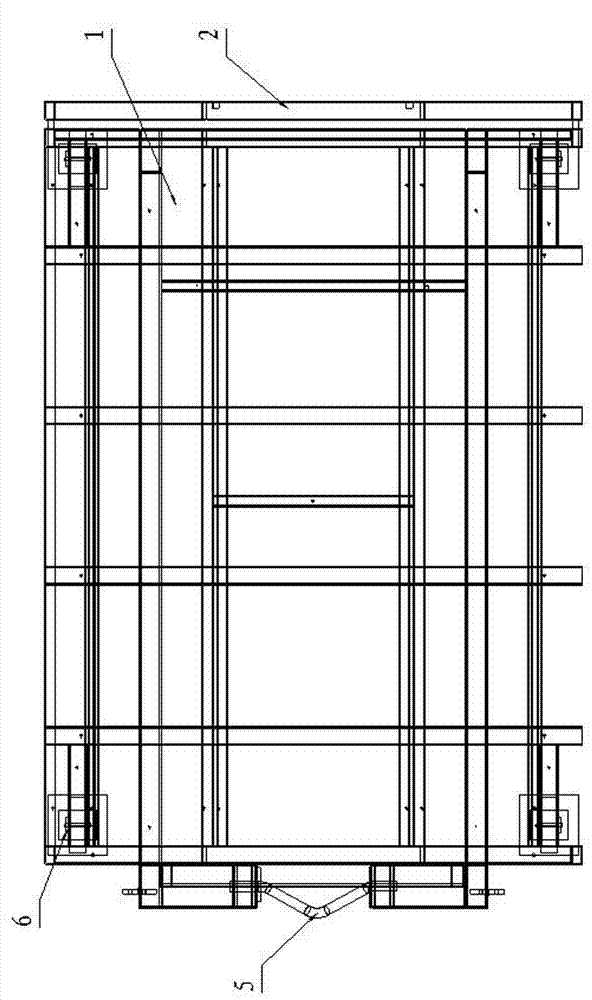

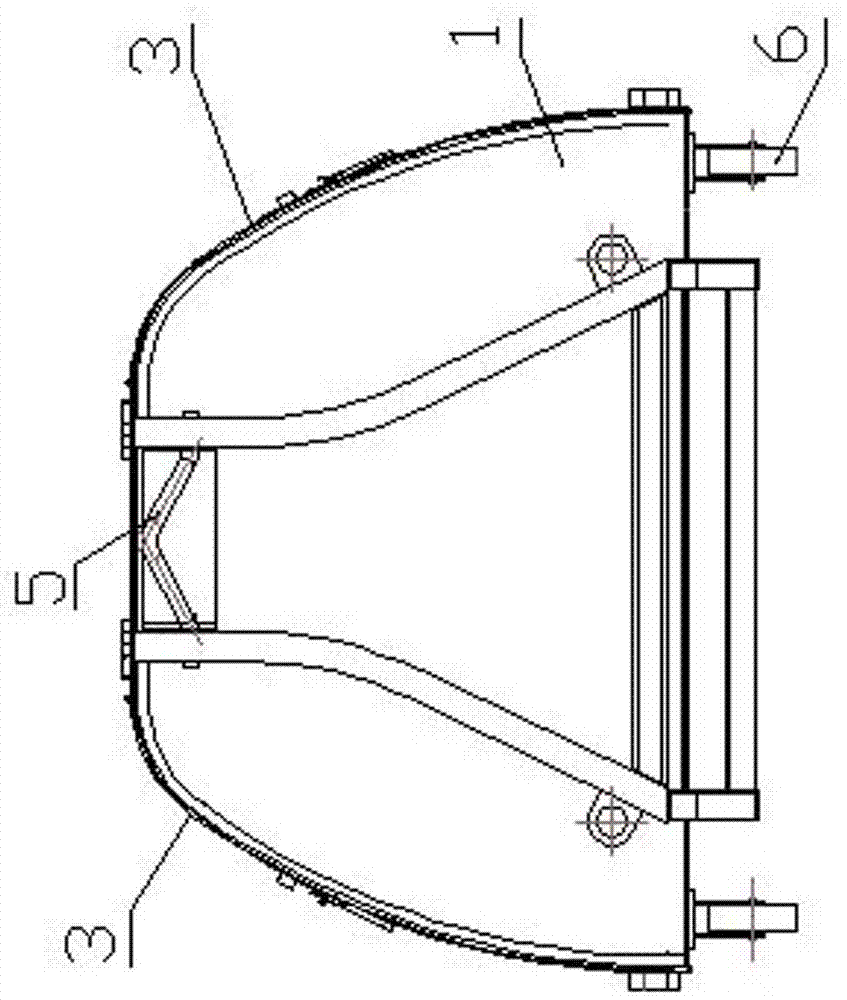

[0023] figure 1 , figure 2 with image 3 The hook-arm garbage bin includes a welding frame welded by multiple longitudinal and beam rectangular square tubes, and carbon steel and sheet metal with phosphating and electrophoretic paint antirust treatment on the surface are installed on the frames on each side. The box body 1 is made of board material; the interior of the box body 1 can also be treated with glass fiber cloth and epoxy glass fiber reinforced plastic coating for anti-corrosion treatment; two garbage input ports 3 are respectively opened on both sides of the top of the box body 1, which is convenient for garbage collection One end of the box body 1 is provided with a dodge door 2, and the opposite end side is provided with a hook arm 5, the hook arm 5 is used to cooperate with a special garbage truck to automatically load and unload garbage; the dodge do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com