Efficient automatic screw feeding device

An automatic and efficient technology, applied in transportation and packaging, conveyor objects, etc., can solve the problems of high processing cost, difficult processing and manufacturing, complex blade structure, etc., and achieve the effect of easy processing and manufacturing, low processing cost and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

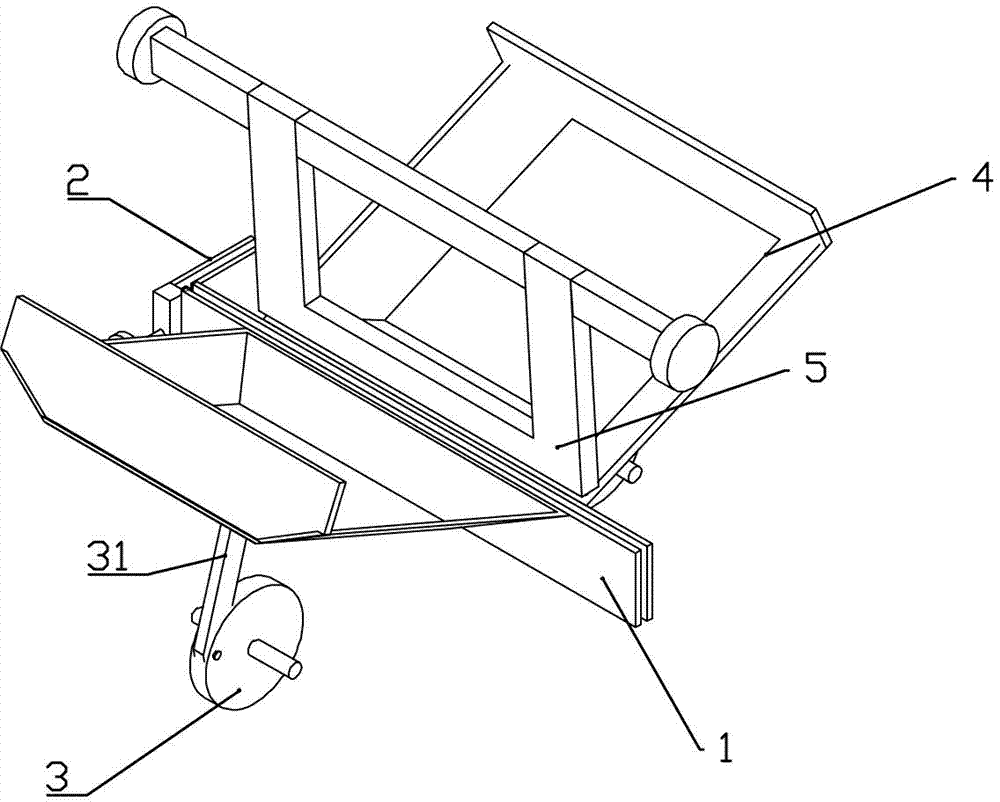

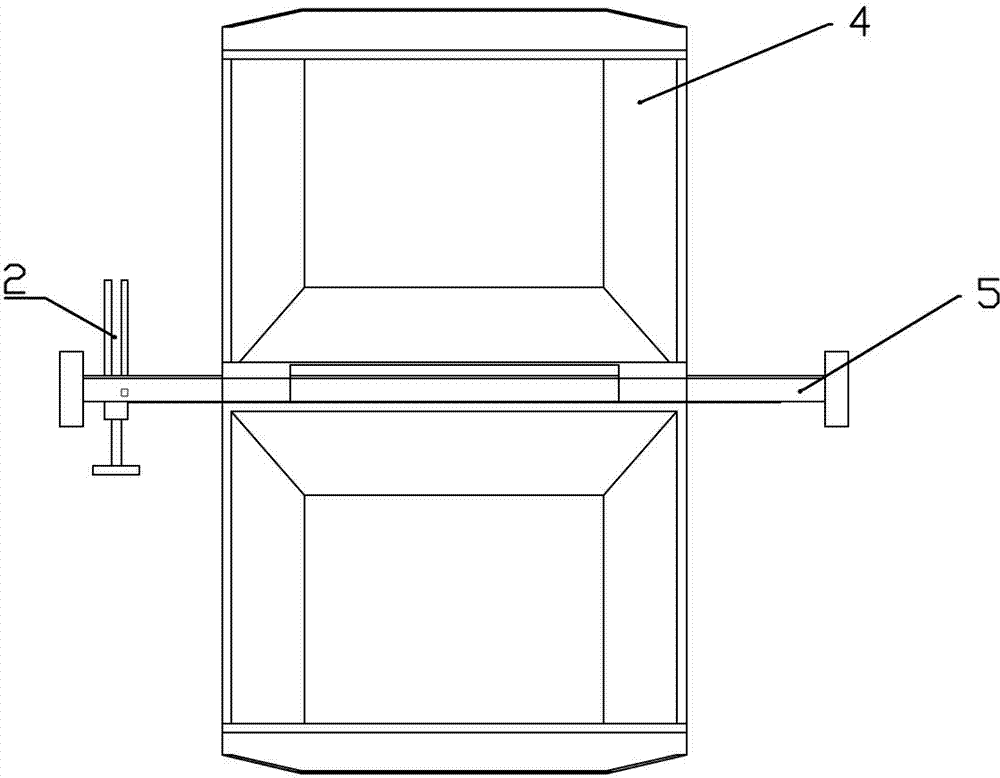

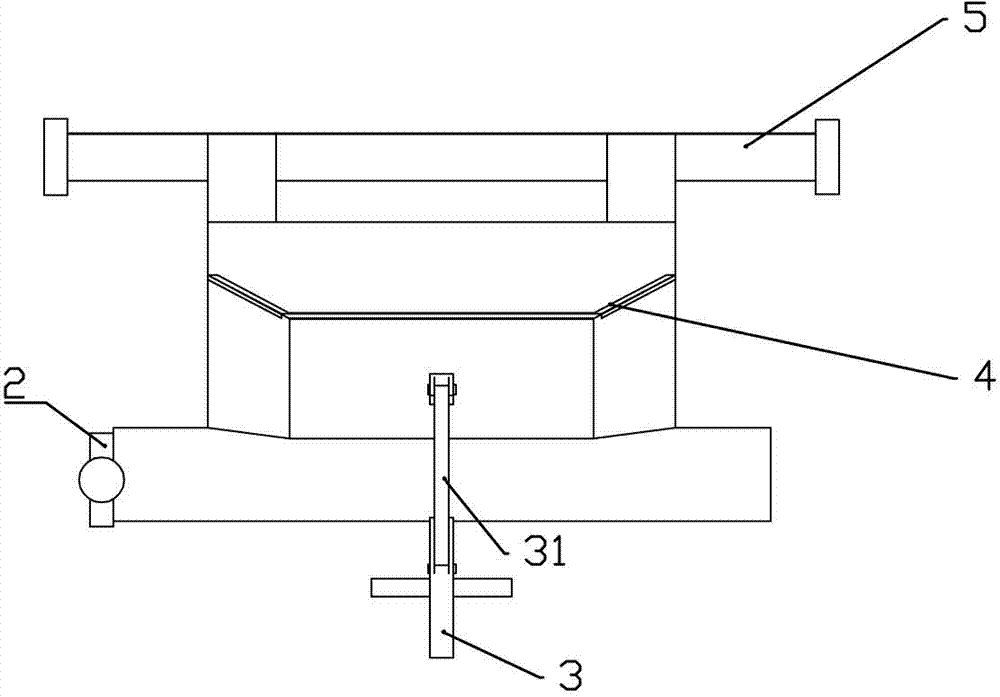

[0018] combined with figure 1 The high-efficiency automatic nail feeding device shown includes an outer shell, on which a feeding port is arranged, and a horizontal conveying track 1 is arranged below the feeding port, and the end of the transverse conveying track 1 is connected to a longitudinal conveying track 2, wherein the transverse conveying track 1 Mirrored rocking plates 4 are arranged on both sides, and one side of the rocking plate 4 near the horizontal conveying track 1 is hinged on the transverse conveying track 1. The rocking plate 4 is box-shaped with an open end, and the inner surface of the box-shaped rocking plate 4 is connected to the bottom The included angle is an obtuse angle, the lower surface of the rocking plate 4 is hinged with a crank rocker 31, the free end of the crank rocker 31 is hinged with a runner, the shaft of the runner is hinged on the outer shell, and the horizontal conveying track 1 is provided with a rejector 5 The rejector 5 is plate-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com