A Side Flow Sludge Upgrading Process

A sludge modification and sludge technology, which is applied in sludge treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of slow sludge discharge, low efficiency and modification speed. Slow and other problems to achieve the effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

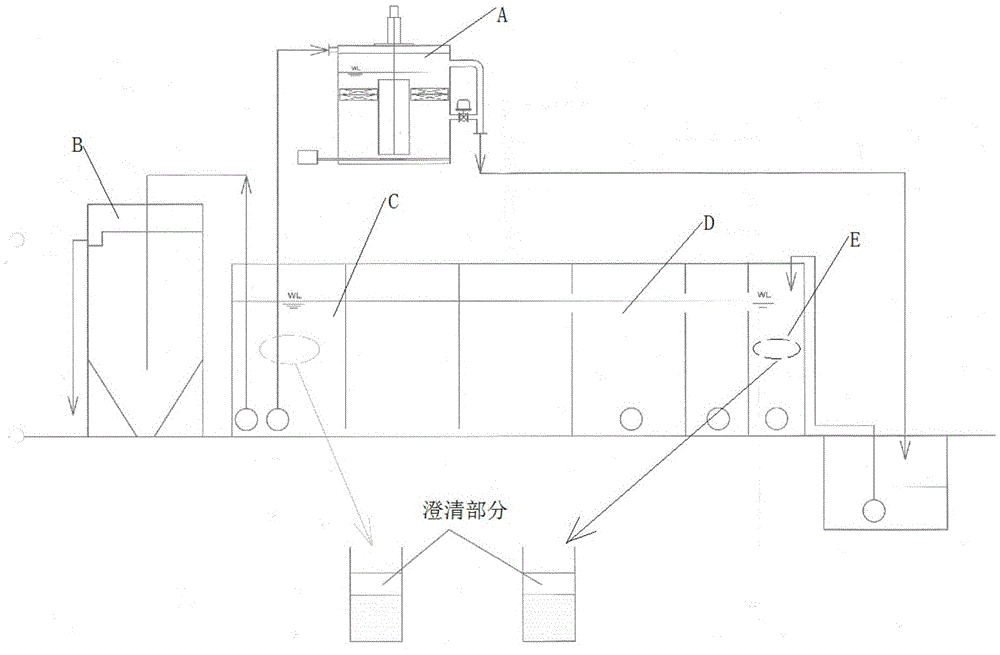

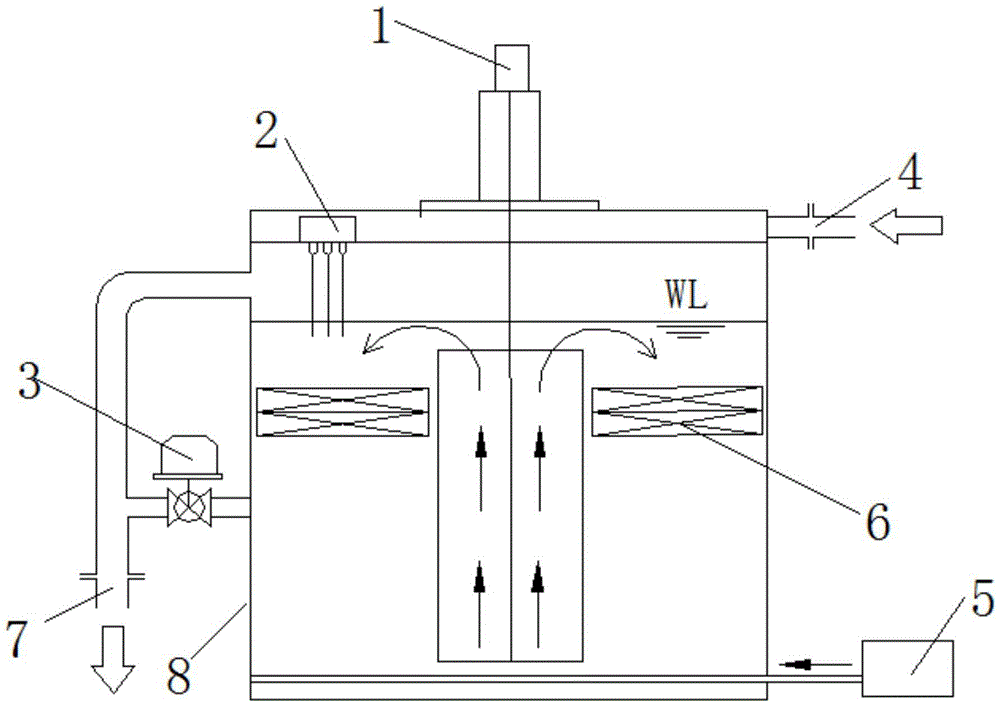

[0017] refer to Figure 1-2 , the present embodiment adopts the following technical solutions:

[0018] A side flow sludge upgrading process of this embodiment, which includes sludge upgrading machine A, sedimentation tank B, aerobic pool C, anoxic pool D, anaerobic pool E, and sludge upgrading machine A The sludge inflow inlet is connected to the aerobic pool C, and anoxic pool D and anaerobic pool E are arranged on one side of the aerobic pool C, and the anaerobic pool E is connected to the sludge storage pool, and the sludge storage pool is connected to the sludge reformer The sludge outlet of A is connected.

[0019] The specific steps are as follows:

[0020] (1) The sludge at the end of the aerobic tank is sent into the sludge reformer through the sludge pump, and then undergoes reforming treatment through the sludge reformer. The sludge discharge and supply project is once a day, at any time ; The mixer and the ventilator are in continuous operation; based on the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com