Treatment device and treatment method for waste drilling fluid

A technology for drilling waste fluid and treatment device, which is applied in mining waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of accelerating flocculation, improving work efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

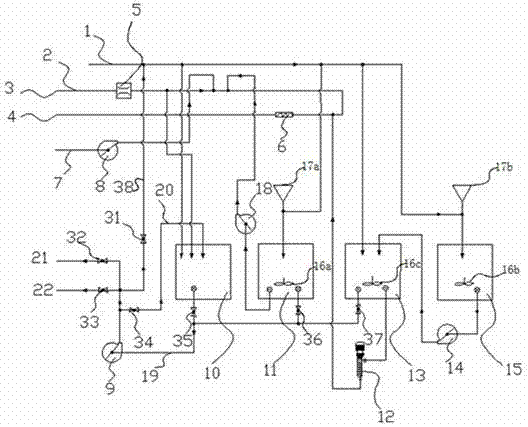

[0030] The treatment device for drilling waste fluid in this embodiment includes a main mixing pipe (2), an acid pipe (7), a water inlet pipe (1), a collection bin (10), a coagulant aid tank (11), and a flocculant storage bin (13 ), a mixing tank (15), characterized in that: the coagulant aid tank (11) and the flocculant storage bin (13) are respectively connected to the main mixing pipe (2), and the mixing tank (15) is connected to the flocculant storage bin (13) , the acid pipe (7) is connected to the main mixing pipe (2) through the acid injection metering pump (8), and the main mixing pipe (2) is provided with a flow meter (5) and a static mixer (6).

[0031] The top of the coagulant aid tank (11) is provided with a feed funnel (17a) connected to the water inlet pipe (1), the inside is provided with an agitator (16a), and the bottom is provided with a pipeline connected to the inlet of the coagulant aid metering pump (18) , the outlet end of the coagulant aid metering pump...

Embodiment 2

[0042] The method for treating drilling waste liquid with a drilling waste liquid treatment device comprises the following steps:

[0043] a. Add water to dilute drilling waste fluid, the ratio of water to drilling waste fluid is 5:1;

[0044] b. The diluted drilling waste fluid enters the main mixing pipe, and the flow rate of the drilling waste fluid is controlled by a flow meter, and the flow rate is controlled at 0.02m 3 / s~0.03m 3 / s, the acid liquid in the acid pipe is pumped into the main mixing pipe through the acid injection metering pump, the pumping volume is 0.02~0.2mL / s, and the acid liquid adjusts the pH value of the drilling waste fluid between 6.5~7.5;

[0045] c. Add the coagulant aid into the coagulant aid tank through the feeding funnel, add clean water through the water inlet pipe, the ratio of clear water to coagulant aid is 20:1, start the agitator to stir the coagulant aid and clear water for 2~6 minutes, Pump the mixed coagulant aid into the main mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com