A kind of water-based graphite lubricant for hot-rolled seamless steel pipe and preparation method thereof

A technology of graphite lubricant and seamless steel pipe, applied in lubricating composition, petroleum industry, etc., can solve problems such as uneven distribution of graphite, uneven distribution of graphite, current fluctuation of continuous rolling mill, etc., and achieve uniform distribution of graphite and good lubricating effect , The effect of rolling current reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0014] As an embodiment of the present invention, a water-based graphite lubricant for hot-rolled seamless steel pipes, the weight percentage of its components is: graphite 25-35%, dispersant 0.5-2%, phosphoric acid Salt 1-3%, resin emulsion 1-2%, thickener 0.5-1%, defoamer 0.1-0.2%, the balance is water, the above-mentioned dispersant is naphthalenesulfonic acid formaldehyde condensate sodium salt, the above-mentioned phosphate It is sodium tripolyphosphate, the above-mentioned resin emulsion is one of styrene-acrylic emulsion or water-based epoxy resin emulsion, and the above-mentioned thickener is one of sodium carboxymethyl cellulose, organic bentonite, xanthan gum, and polyacrylamide Or a mixture of several, the above-mentioned defoamer is simethicone emulsion.

[0015] As a preferred embodiment, the proportion by weight of the components of the water-based graphite lubricant for hot-rolled seamless steel pipes is: graphite 30%, dispersant 0.5%, phosphate 1.5%, resin emul...

Embodiment 1

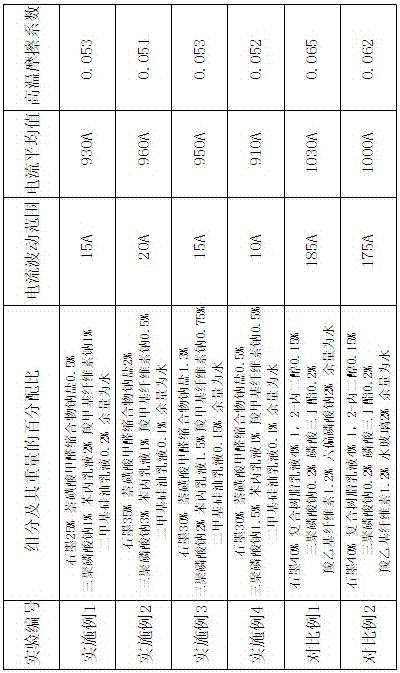

[0026] At normal temperature and pressure, according to the attached figure 1 According to the weight ratio given in , first add water, graphite and naphthalenesulfonic acid formaldehyde condensate sodium salt into the reactor and stir for 30 minutes, then add styrene-acrylic emulsion and sodium tripolyphosphate into the reactor and stir for 20 minutes, and finally add carboxylate Sodium methylcellulose and simethicone emulsion were added into the reactor and stirred for 1 hour to obtain the water-based graphite lubricant of this embodiment. Thereafter, the obtained water-based graphite lubricant was divided into two parts, one part was used to test the high-temperature friction coefficient, and the other part was used to roll Φ89mm seamless steel pipes in the continuous rolling mill, and the current fluctuation data of the continuous rolling mill during the production process were recorded Range and current average value, the above-mentioned high temperature friction coeffici...

Embodiment 2

[0028] Embodiment 2 is compared with embodiment 1, only the weight proportion of each component changes, and other contents are exactly the same, and the weight proportion of each component of embodiment 2 is in appended figure 1 Listed in, this will not go into details, the high temperature friction coefficient value, current fluctuation data range and current average value of embodiment 2 are also in the appended figure 1 listed in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com