Novel melted iron inoculation device

A new type of molten iron technology, applied in the field of new molten iron inoculation devices, can solve the problems of difficult manual control, decline in spheroidization, inaccurate dosage, etc. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

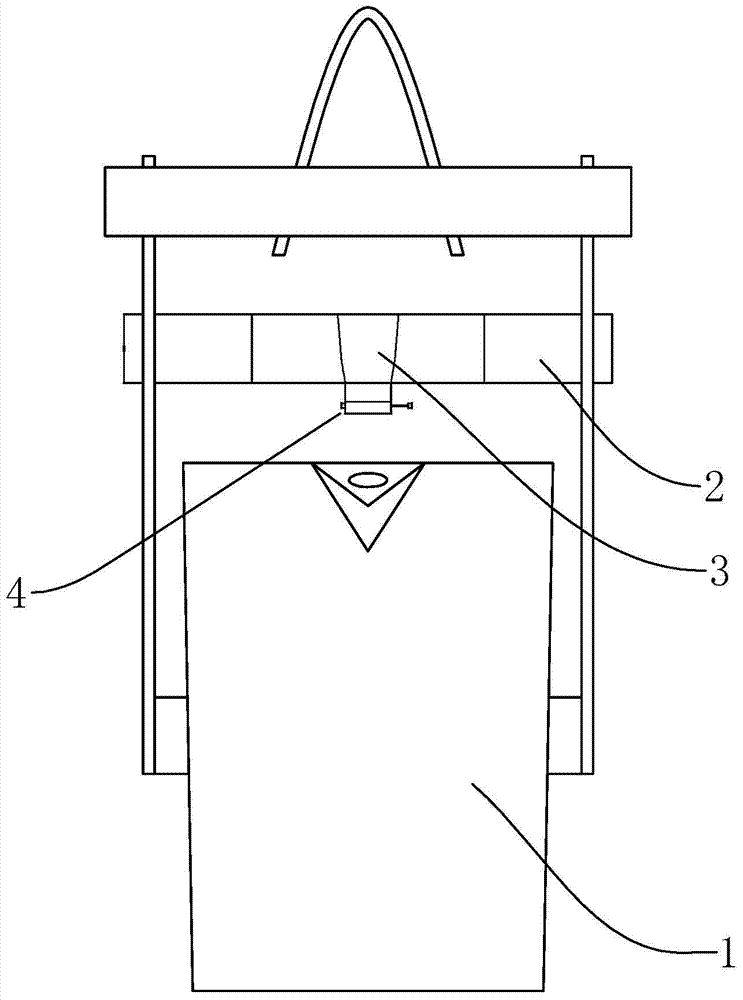

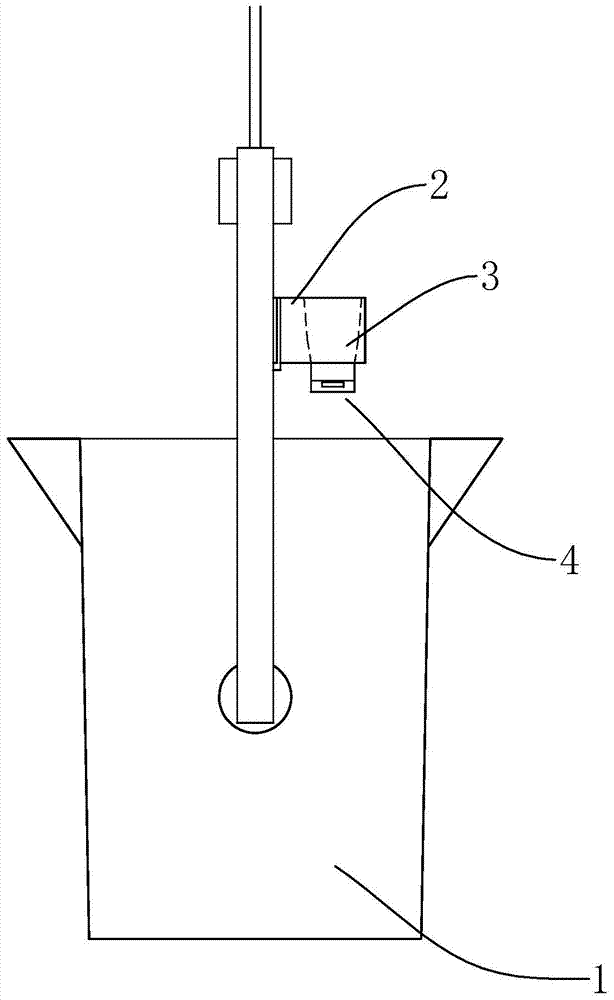

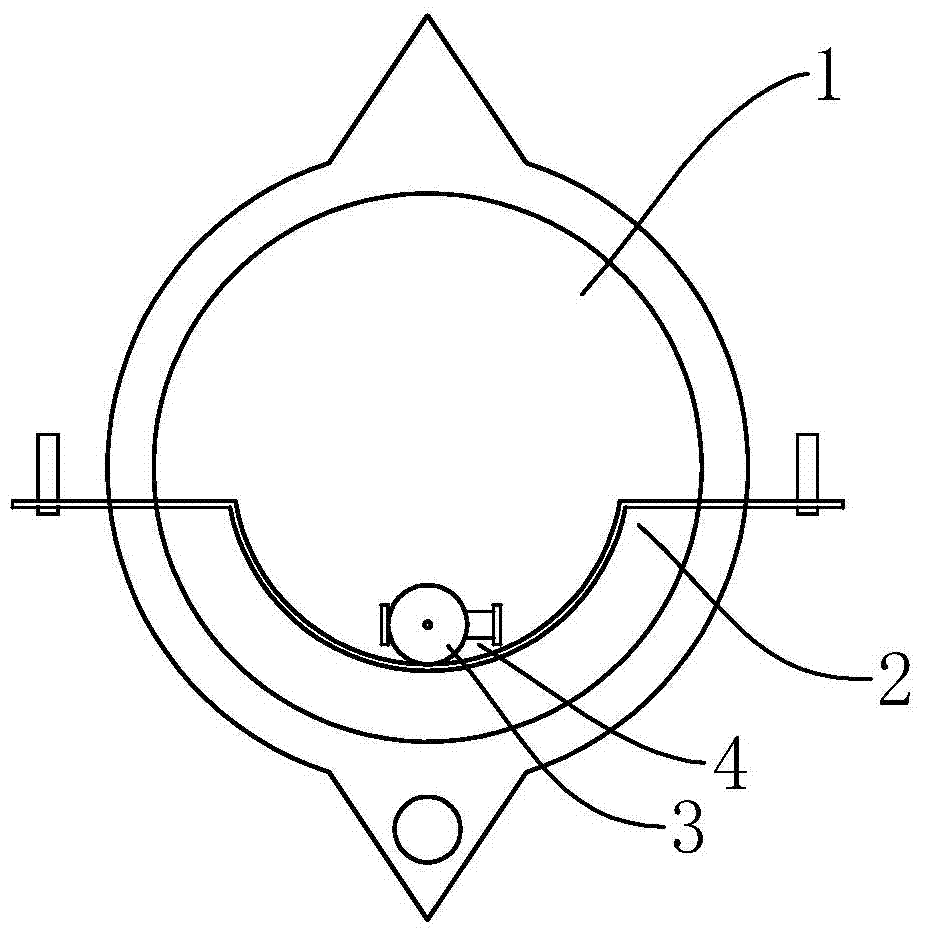

[0023] refer to Figure 1 to Figure 9 , Figure 1 to Figure 9 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a new type of molten iron inoculation device includes a mounting frame 2 mounted on the handle of the molten iron bucket 1, and an inoculation barrel mounted on the mounting frame 2. 3. The flow control device 4 installed under the inoculation barrel 3, the flow control device 4 includes an installation joint 41 and a switch gate 42, the installation joint 41 is provided with a through hole 43, and the switch gate 42 is horizontal Through the installation joint 41 and cut off the through hole 43, the switch gate 42 is provided with at least one flow hole 44, as preferably, in this embodiment, the flow hole 44 is provided with three, and the three flow holes The caliber of 44 is inconsistent, so that during use, the flow rate of the inoculant can be adjusted according to the molten iron of different materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com