Hot wind layered heating type re-stirring locomotive

A remix locomotive and hot air technology, which is applied in road repair, roads, roads, etc., can solve the problems of uneven temperature, temperature segregation, poor mobility of remix locomotives, etc., and achieve the effect of sufficient and uniform mixing temperature and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

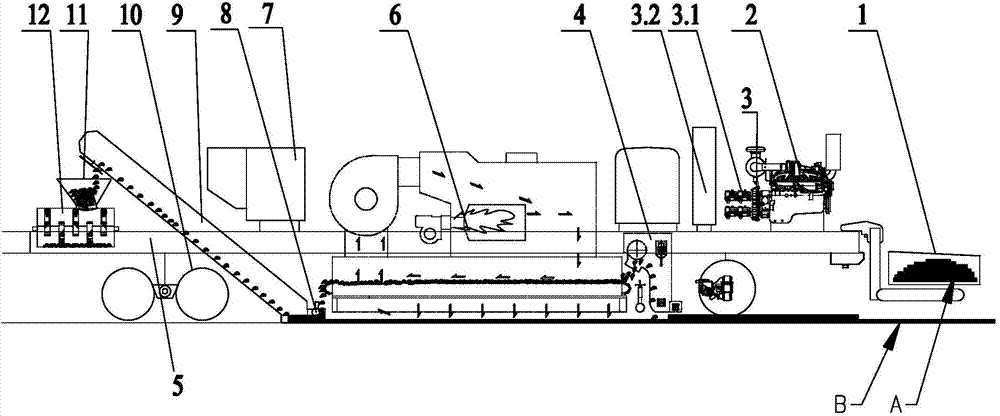

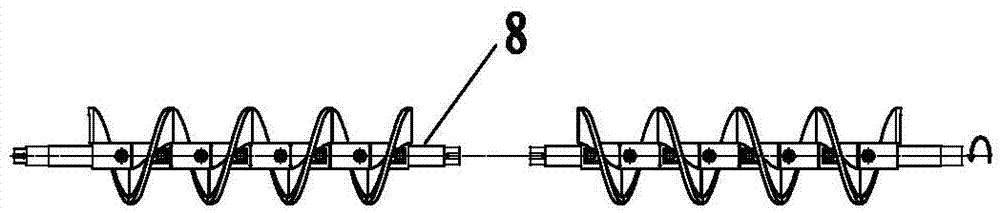

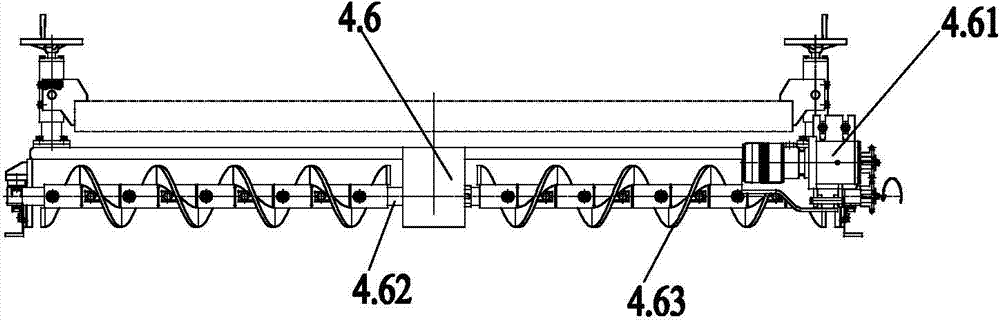

[0022] Figure 1~6 Including new material receiving hopper 1, diesel engine 2, hydraulic power mechanism 3, hot material vertical lifting device 4, casing 4.1, tensioner 4.2, mounting seat 4.21, bar groove 4.22, adjusting shaft seat 4.23, adjusting bolt 4.24. Conveying drive plate chain 4.3, scraper 4.4, scraper bracket 4.5, screw feeding device 4.6, drive motor 4.61, conveying shaft 4.62, spiral blade 4.63, drive blade 4.64, first gear 4.65, second gear 4.66, Scraper chain drive motor 4.7, grinding plate 4.9, discharge port 4.10, frame 5, hot air circulation heating device 6, diesel burner 6.1, combustion chamber 6.2, conveyor plate chain 6.6, circulation upper air duct 6.7, circulation air lower air duct 6.8 , circulating fan 6.10, air vent 6.11, frame installation platform 6.9, fuel tank 7, aggregate screw roller 8, scraper lifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com