Lining connecting structure applicable to jacking pipe for implementing connection passage

A technology for connecting structures and connecting channels, applied in tunnel lining, wellbore lining, tunnels, etc., can solve the problems of high construction cost, long construction period, and environmental pollution of surrounding soil, so as to reduce construction cost, low maintenance cost, and ensure construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The purpose of the present invention is achieved through the following technical solutions:

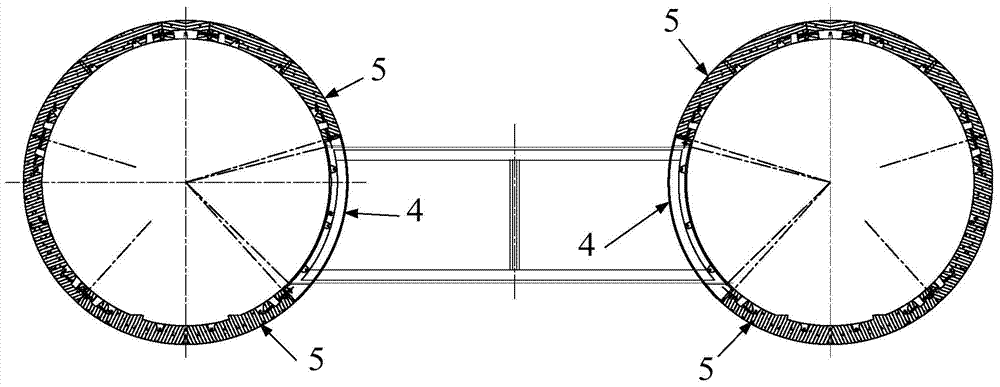

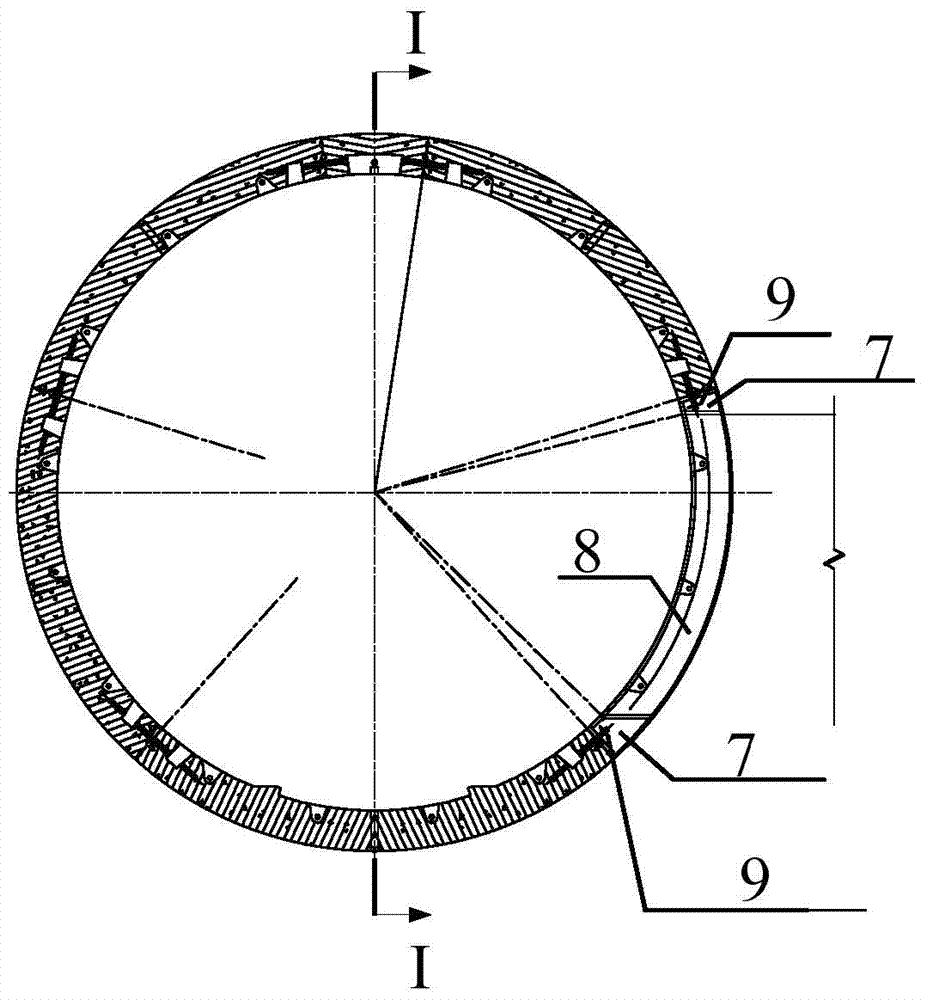

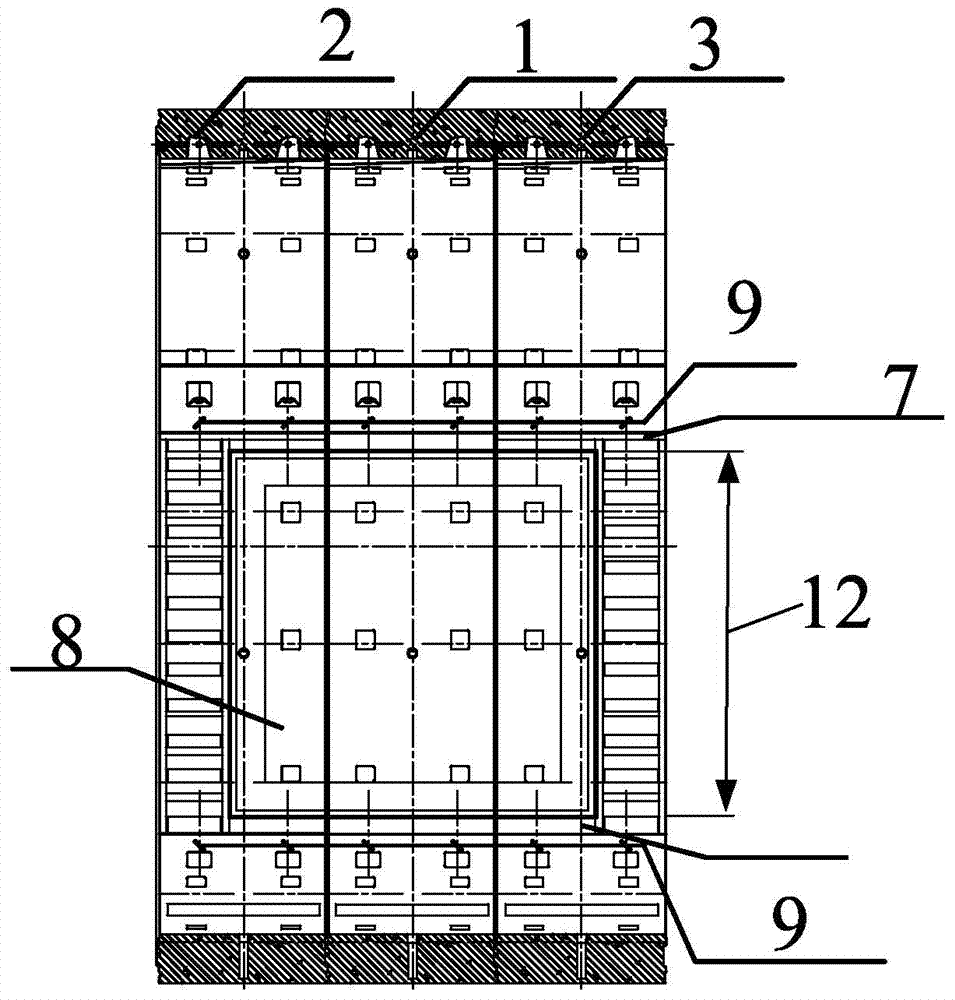

[0038] Such as Figure 1-8 As shown, the present invention designs a special segment at the segment corresponding to the position of the main tunnel in the inter-area communication passage, adopts the combined design of the steel plate structure filled with concrete and the concrete segment, and leaves the interface position of the pipe jacking segment of the communication passage. The pipe jacking method is used to construct the communication channel. After the pipe jacking is completed, the ring beam at the opening is poured to form an integral communication channel structure.

[0039] During specific construction, the lining connection structure suitable for pipe jacking to implement communication channels mainly includes the following steps:

[0040] 1) if Figure 1~3 As shown, during the construction of the main tunnel, the pipes in the three annular lining rings arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com