Offset type pressure relief device of membrane pump

A technology of pressure relief device and diaphragm pump, which is applied to the components of pumping device for elastic fluid, pump components, and variable displacement pump components, etc. problems, to achieve the effect of saving the cost of injection molding materials, reducing the cost of the mold, and simplifying the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

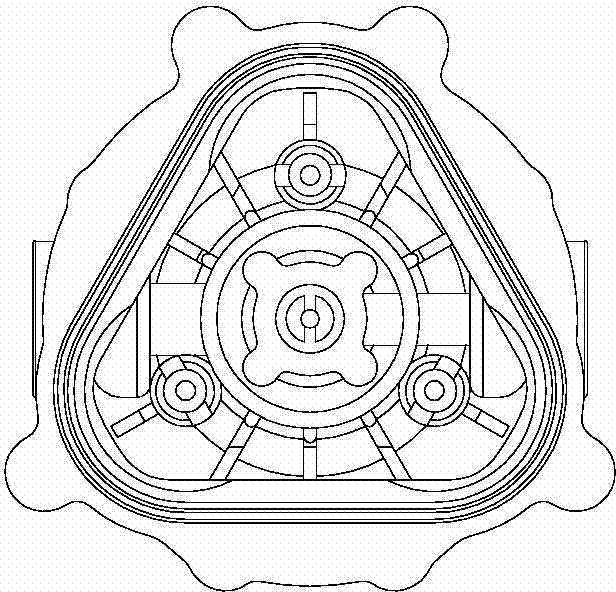

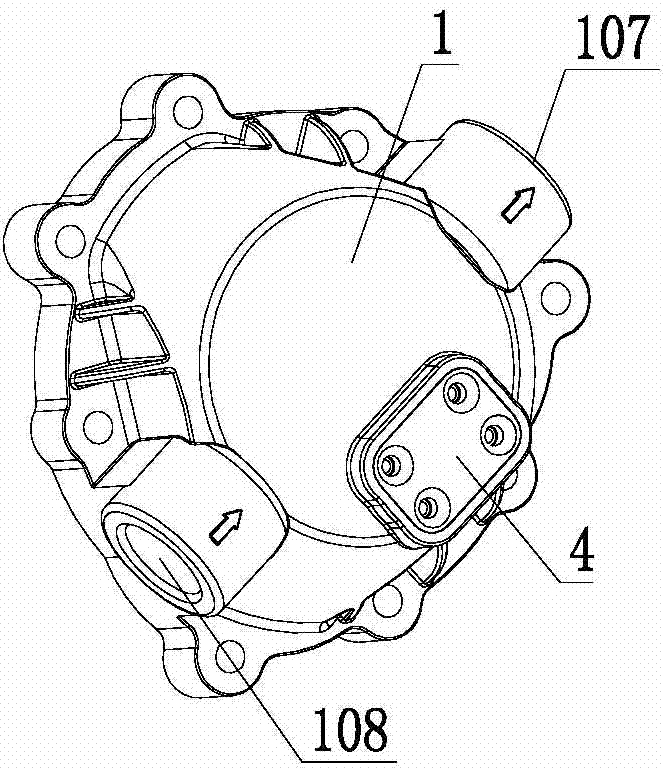

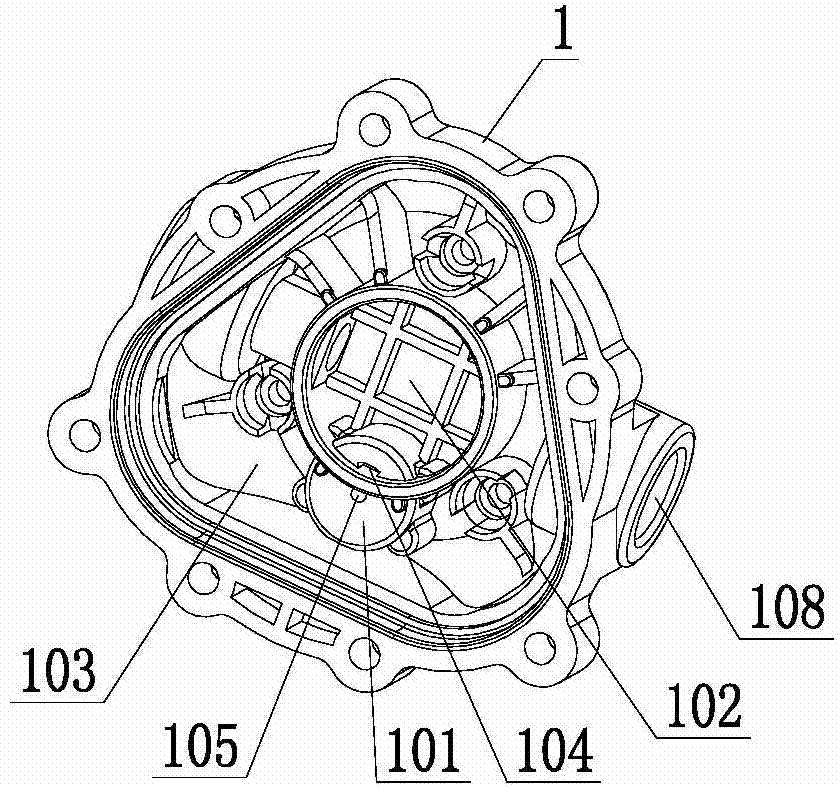

[0013] Such as Figure 2-4 As shown, a bias pressure relief device of a diaphragm pump, the pump cover 1 constituting the diaphragm pump is divided into a high-pressure chamber 102 and a low-pressure chamber 103 by a collector plate. The high-pressure chamber 102 is located in the center of the pump cover 1 and communicates with the water outlet hole 107 of the diaphragm pump. The low-pressure chamber 103 is located at the periphery of the high-pressure chamber 102 and communicates with the water inlet 108 of the diaphragm pump. The pressure relief device is arranged on the pump cover body 1, and includes an inwardly recessed chamber 101 formed on the pump cover body 1; a high-altitude hole 104 and a high-altitude hole 104 which are respectively connected to the high-pressure chamber 102 and the low-pressure chamber 103 of the diaphragm pump in the chamber 101. The low-pressure hole 105; the piston 2, the spring 3 and the cover 4 installed in the chamber 101 in sequence. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com