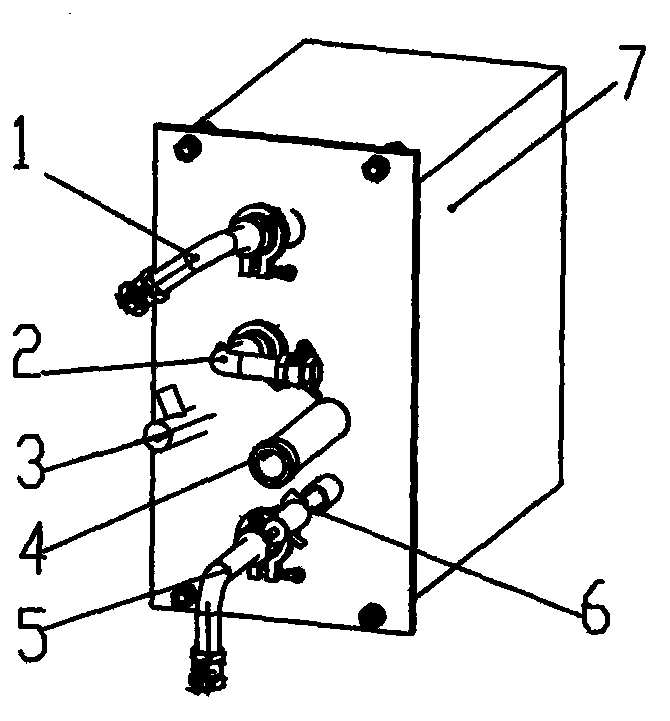

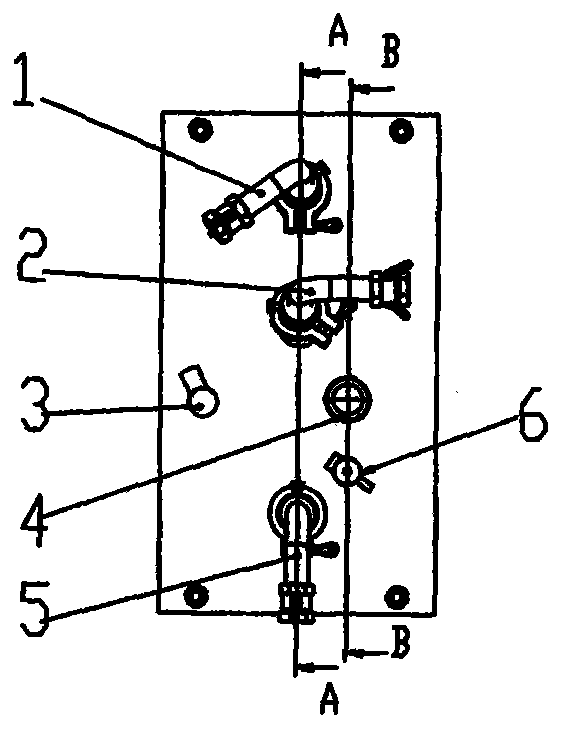

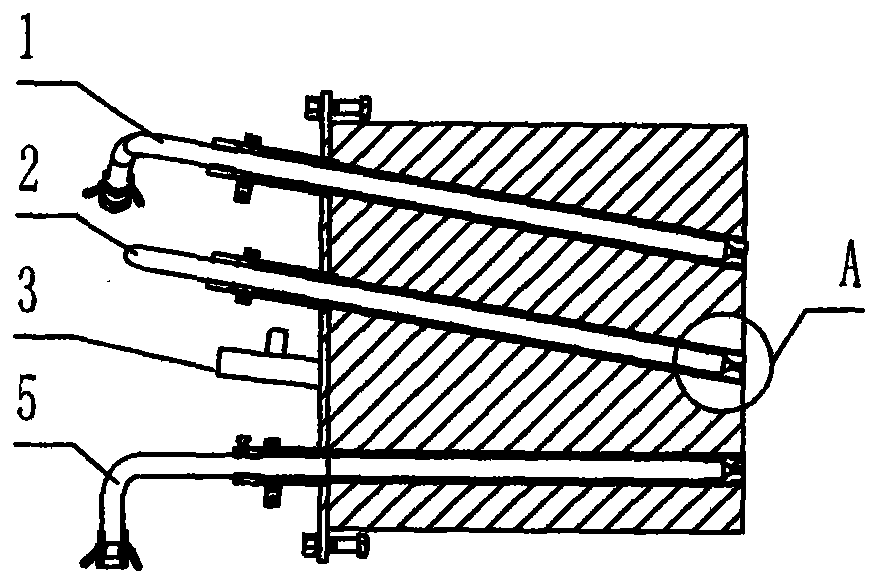

Oxygen-rich gas combustion device and oxygen-rich gas combustion method

A gas combustion and combustion device technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of environmental pollution, waste of energy, etc., and achieve the effects of rapid heating, large heating coverage, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0032] Embodiment 2: the combustion method of multi-oxygen gas combustion device, carry out the following steps:

[0033] 1) Detect and adjust the oxygen supply system:

[0034] (1) Adjust and stabilize the oxygen supply pressure: adjust the pressure stabilizing valve to stabilize the oxygen pressure supplied by the oxygen supply system within the design pressure range, which is 50KPa; adjust with the output pressure of the oxygen supply equipment and the pressure of the oxygen pipeline, Ensure that the oxygen pressure of the combustion device is stable;

[0035] (2) Adjust oxygen flow: the controller adjusts the oxygen supply through the primary oxygen flow meter, primary oxygen regulating valve, secondary oxygen flow meter, and secondary oxygen regulating valve; Oxygen accounts for 80% of the total oxygen;

[0036] 2) PLC control function detection: Through the oxygen pressure transmitter and flowmeter, the change of oxygen pressure and flow is transmitted to the PLC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com