Jet flow heat radiationmechanism and jet flow heat radiator

A heat dissipation mechanism and heat sink technology, which is applied in the field of jet heat dissipation mechanism, heat dissipation mechanism, and jet heat sink, can solve the problems of poor effect, achieve good effect, prevent damage, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment A jet cooling mechanism

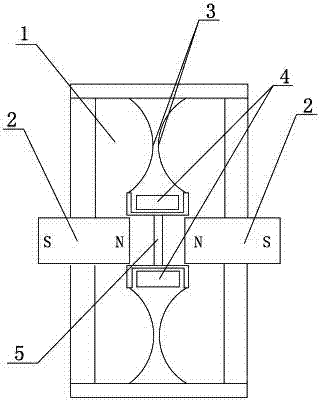

[0038] This embodiment is a jet cooling mechanism, such as figure 1 As shown, it includes:

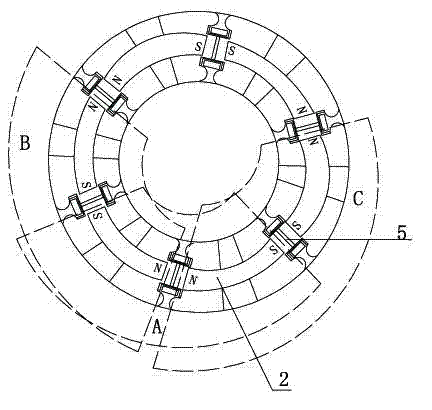

[0039] The cavity 1 composed of the outer casing and the diaphragm is fixed with two magnets 2 arranged at intervals in the cavity 1. In this embodiment, a permanent magnet is used, and the two magnetic poles of the two magnets 2 have the same polarity. Relative setting, that is, the N poles of the two magnets are set oppositely, or the S poles of the two magnets are set oppositely. An electromagnet mechanism is arranged between the two magnets, and the electromagnet mechanism can move towards any magnet 2 under the action of the magnetic force of the two magnets 2. The tympanic membrane 3 is fixed on the electromagnetic mechanism, and the cavity 1 A first air port and a second air port connecting the cavity with the outside are also provided on the top.

[0040]Described electromagnetic mechanism comprises the electromagnet 4 that magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com