Parallel calibration and inspection method and system for built-in inertial components of vehicle-mounted obd equipment

A calibration method and equipment technology, applied in the field of calibration and inspection methods and systems thereof, can solve the problems of long calibration period and inability to achieve batch calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

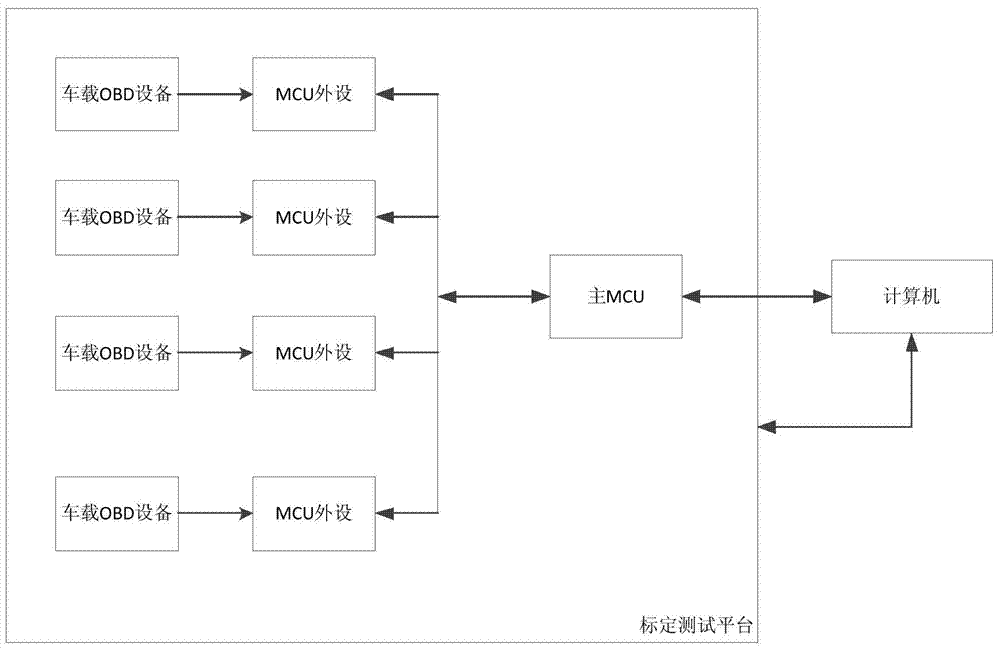

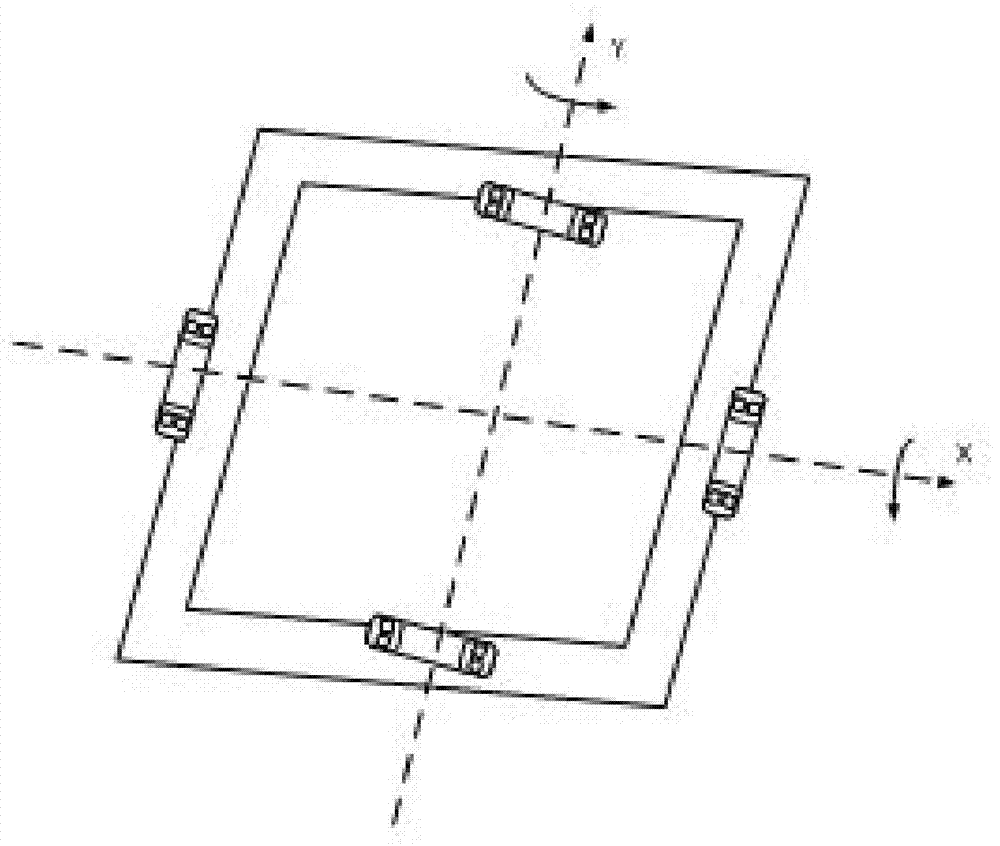

[0063] Example: such as Figure 1-2 As shown, a parallel calibration and verification system for built-in inertial components of a vehicle-mounted OBD device, including a calibration test platform, multiple MCU peripherals, a main MCU and a computer; multiple vehicle-mounted OBD devices to be calibrated form a group and are installed in the calibration On the equipment installation base of the test platform, the base is also equipped with MCU peripherals connected to each vehicle-mounted OBD device and a main MCU connected to each MCU peripheral. Each vehicle-mounted OBD device corresponds to each MCU peripheral. , the calibration test platform is a rotating platform, which is composed of two independently rotatable shaft frames, the middle vertical surface fixed by the two shaft frames is the equipment installation base, the X-axis is the outer frame, and the Y-axis is the inner frame The X-axis corresponds to the outer shaft frame of the calibration test platform, and the Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com