Intelligent test system based on TEDS sensor and matrix switch technology and test method thereof

A matrix switch and test system technology, applied in the direction of instruments, measuring devices, and reducing unwanted effects, can solve the problems of increasing test costs, unsatisfactory results, and large manpower costs, and achieve simple structure, error avoidance, and application broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

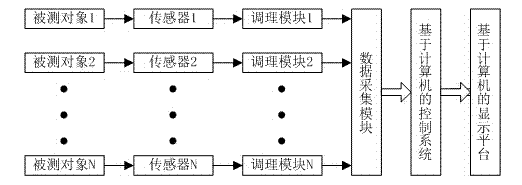

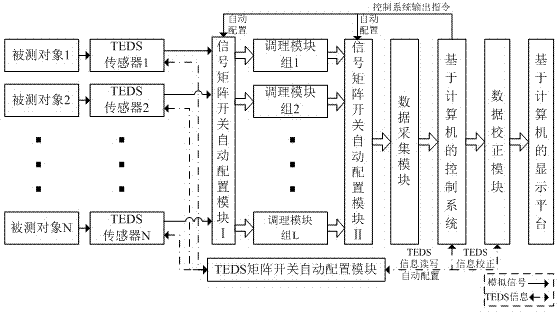

[0049] Embodiment one An Intelligent Test System Based on TEDS Sensor and Matrix Switch Technology

[0050] The present embodiment is an intelligent test system based on TEDS sensor and matrix switch technology, such as figure 2 As shown, it includes:

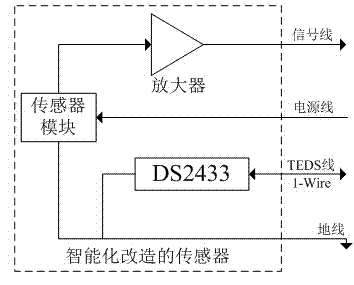

[0051] (1) Signal conditioning automatically configures the matrix switch module, which is used to transmit the signal collected by the external TEDS sensor to the corresponding signal conditioning module. The signal conditioning in this embodiment automatically configures the matrix switch module such as Figure 4b As shown, its topological structure is (L×M)×N, that is, there are LⅹM rows and N columns of switching channels, and the intersection of each row and each column is a switching channel, and each column of channels (c 0 to c N-1 The channel in ) corresponds to the only external TDES sensor, that is, the information collected by each TEDS sensor can only be transmitted through a unique column channel; and each r...

Embodiment 2

[0062] Embodiment two A testing method of intelligent testing system based on TEDS sensor and matrix switch technology

[0063] A kind of test method utilizing above-mentioned intelligent test system based on TEDS sensor and matrix switch technology, such as Figure 5 The following steps are shown:

[0064] (1) Read TEDS information: the control module sequentially reads and scans the TEDS information of the sensors connected to the measured object through the channels of the TEDS matrix switch automatic configuration module.

[0065] The TEDS information of the sensor in this embodiment includes basic TEDS information and standard TEDS information, wherein the basic TEDS information contains necessary sensor identification information, that is, identification parameters, such as manufacturer, serial number, version number and data code. The standard TEDS information includes sensor-specific "data sheet" information, generally the data required to correctly configure the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com