Aircraft fuel measuring and controlling system with self compensation capacitance type level sensor

A technology of liquid level sensor and measurement and control system, which is applied in the direction of liquid level indicator for physical variable measurement, etc., can solve the problems of difficult realization and cumbersome workload, and achieves a solid mechanical structure, simplifies the mechanical structure, and improves the adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

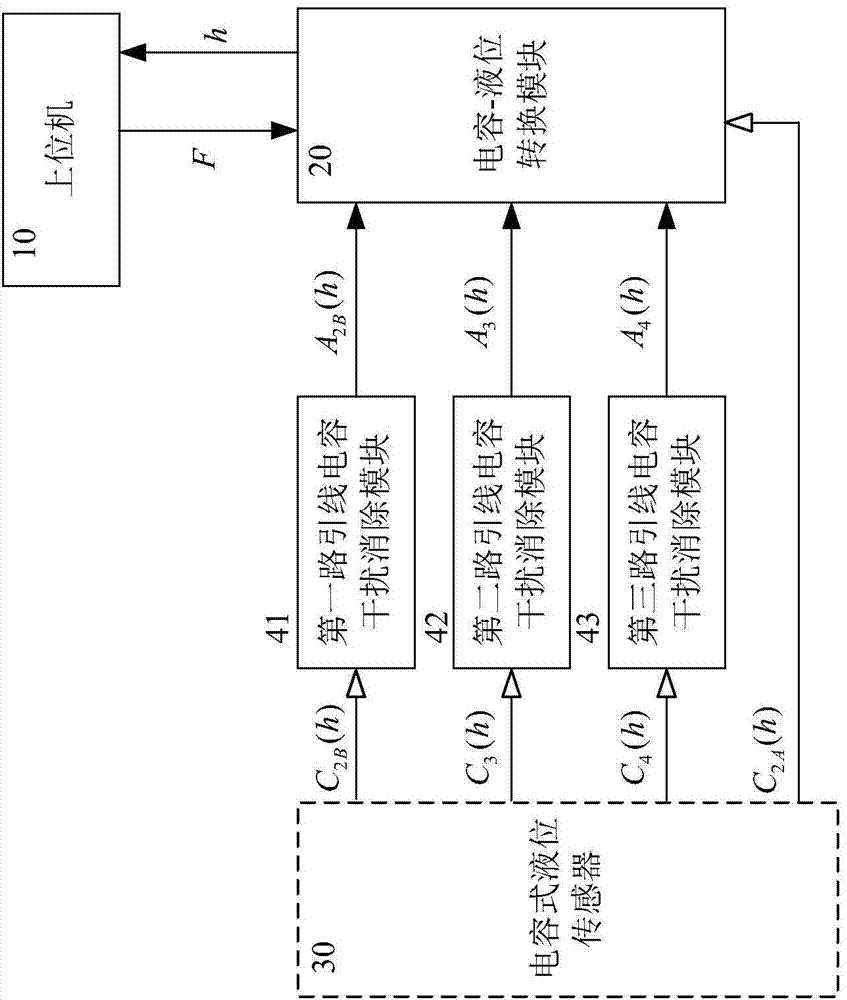

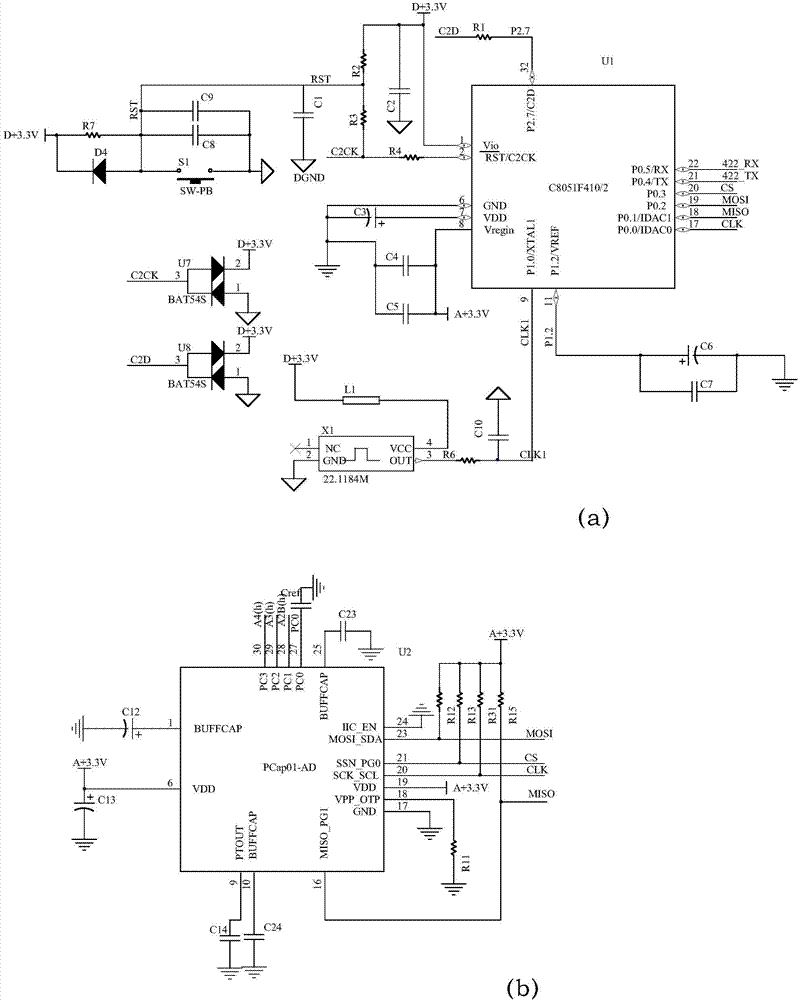

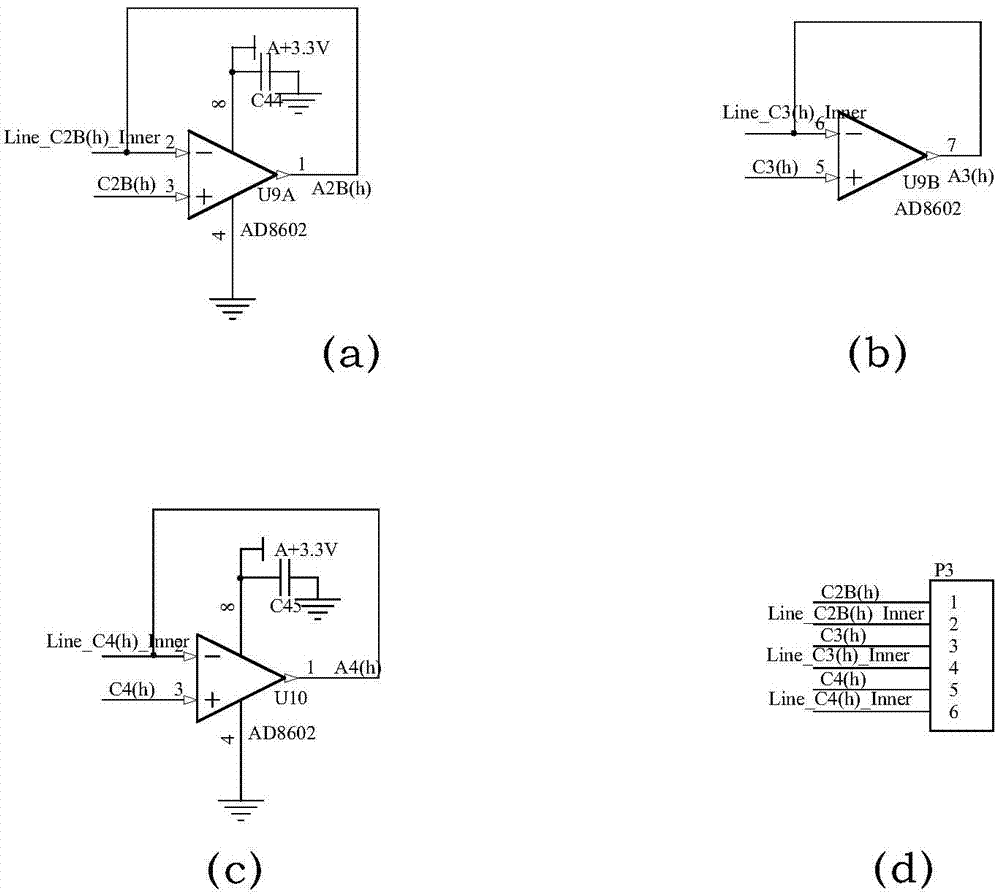

[0039] see figure 1 As shown, the present invention has designed a kind of aircraft fuel quantity measurement and control system with self-compensating capacitive liquid level sensor, and this system includes measuring circuit board 40, capacitive liquid level sensor 30, capacitance-liquid level conversion module 20, the first One lead capacitance interference elimination module 41 , the second lead capacitance interference elimination module 42 , the third lead capacitance interference elimination module 43 and the host computer 10 . The structure of the capacitive liquid level sensor 30 is as follows Figure 4 ~ Figure 10 shown.

[0040]In the present invention, the upper computer 10 is composed of a computer and aircraft fuel oil quantity measurement and control software. On the one hand, the aircraft fuel oil quantity measurement and control software is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com