FPGA-based cement thickness tester

A technology of measuring instrument and consistency, which is applied in the field of cement consistency measuring instrument based on FPGA, can solve the problems that the accuracy can only reach 1mm, prolong the operation time of experimenters, increase the repetitive workload of experimenters, etc., to improve the measurement accuracy and improve Anti-jamming ability and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

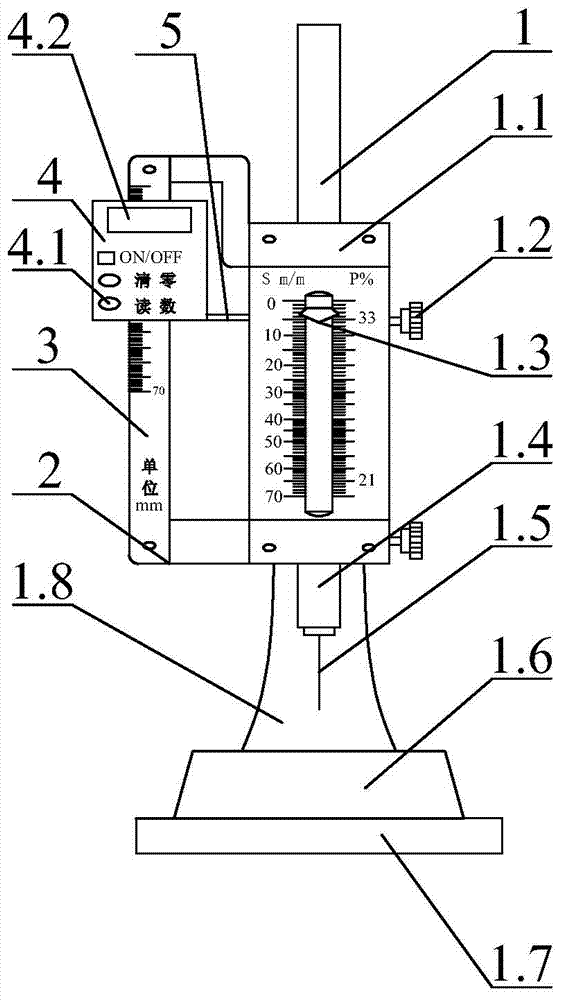

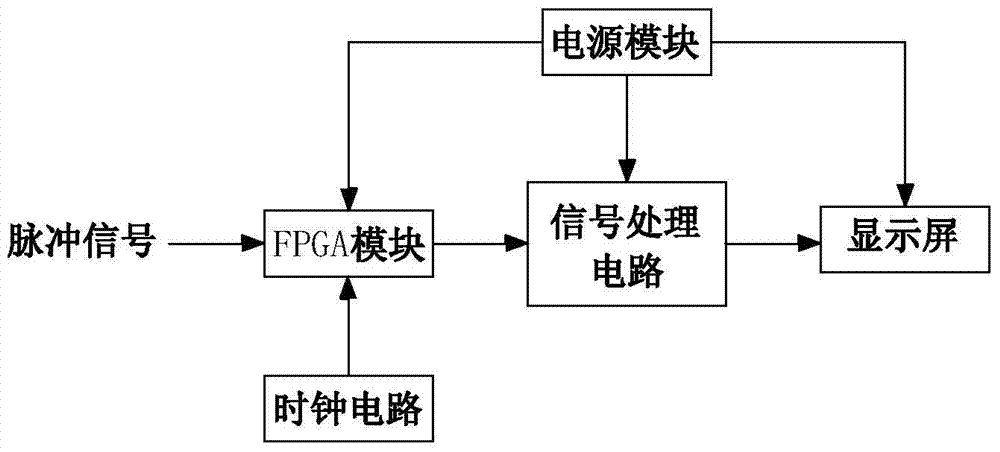

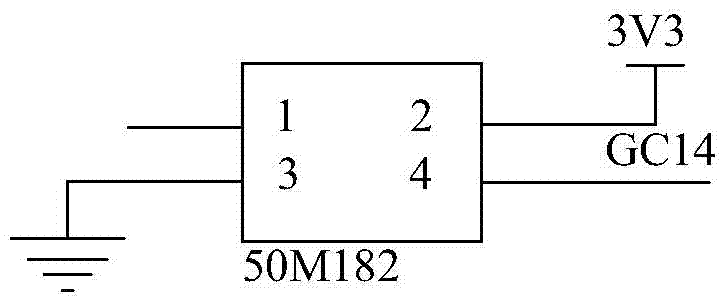

[0024] Such as Figure 1-5 As shown, a cement consistency measuring instrument based on FPGA includes a manually operated Vicat instrument 1, which belongs to existing equipment, and one side of the manually operated Vicat instrument 1 is provided with a needle penetration measuring device 2. The penetration measurement device 2 includes a capacitive scale 3 and a digital display meter 4 containing an FPGA detection system. The digital display meter 4 can be vertically moved on the capacitive scale 3. The value board 1.1 is connected, and the pointer 1.3 on the value display board 1.1 is connected with the digital display meter 4 through the linkage rod 5 . The digital display meter 4 includes an external button 4.1 and a display screen 4.2, and an internal FPGA detection system. Both the button 4.1 and the display screen 4.2 are connected to the FPGA detection system; the button 4.1 includes a switch button (ON / OFF), a clear Zero button and read button. The FPGA detection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com