DSP-based transformer station indoor humiture and dust control system

A dust control, temperature and humidity technology, applied in the field of substation maintenance, can solve problems such as inadequate dust treatment, complicated lines, and poor performance, and achieve the effects of reducing labor costs and preventing high-temperature burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

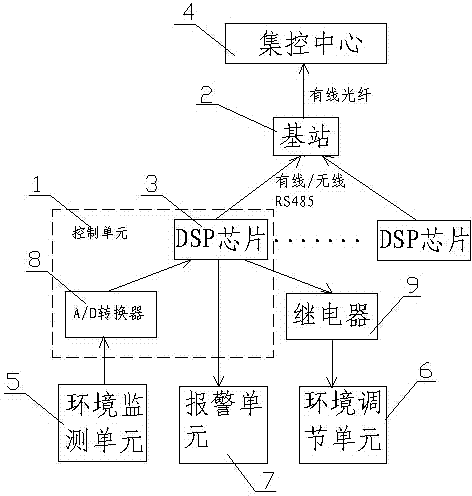

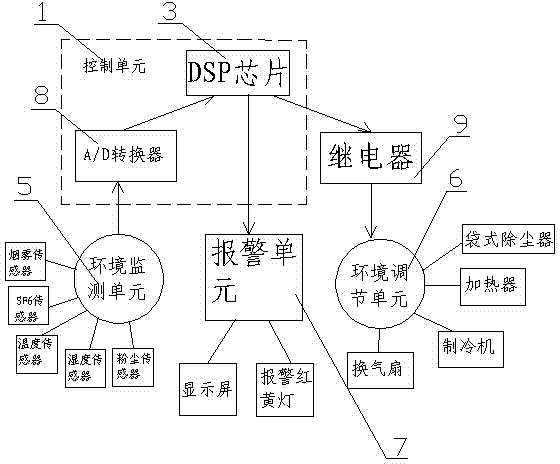

[0033] Such as figure 1 with image 3 Shown: the present invention provides a kind of DSP-based substation indoor temperature and humidity and dust control system, including control unit 1, environment detection unit 5, environment adjustment unit 6, alarm unit 7, base station 2 and centralized control center 4, described Environmental monitoring unit 5 comprises temperature sensor, humidity sensor and dust sensor, and described environmental conditioning unit 6 comprises refrigerating machine, heater, ventilation fan and bag filter, and described control unit 1 and described environmental detection unit 5, alarm unit 7 It is connected with the environmental adjustment unit 6 signal, the control unit 1, the base station 2, and the centralized control center 4 are connected in sequence, the control unit 1 is connected with the base station 2 through RS485, and the base station 2 is connected with the base station through a wired optical fiber. The centralized control center 4 ...

Embodiment 2

[0037] Such as figure 1 with image 3 Shown: the present invention also provides a kind of DSP-based substation indoor temperature and humidity and dust control system, including control unit 1, environment detection unit 5, environment adjustment unit 6, alarm unit 7, base station 2 and centralized control center 4, all The environmental monitoring unit 5 includes a temperature sensor, a humidity sensor and a dust sensor, the environmental conditioning unit 6 includes a refrigerator, a heater, a ventilation fan and a bag filter, and the control unit 1 is connected to the environmental detection unit 5 and the alarm unit. 7 is connected to the environment adjustment unit 6 with signals, the control unit 1, the base station 2, and the centralized control center 4 are connected in turn, the control unit 1 is connected to the base station 2 through RS485, and the base station 2 is connected through a wired optical fiber Connect with the centralized control center 4.

[0038] Th...

Embodiment 3

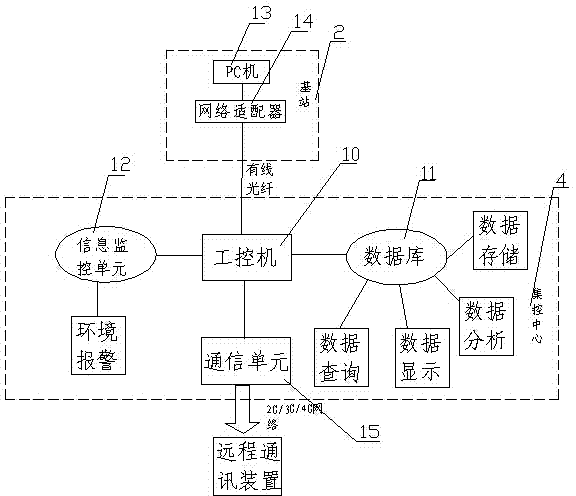

[0042] Such as figure 1 , figure 2 with image 3 Shown: the present invention also provides a kind of DSP-based substation indoor temperature and humidity and dust control system, including control unit 1, environment detection unit 5, environment adjustment unit 6, alarm unit 7, base station 2 and centralized control center 4, all The environmental monitoring unit 5 includes a temperature sensor, a humidity sensor and a dust sensor, the environmental conditioning unit 6 includes a refrigerator, a heater, a ventilation fan and a bag filter, and the control unit 1 is connected to the environmental detection unit 5 and the alarm unit. 7 is connected to the environment adjustment unit 6 with signals, the control unit 1, the base station 2, and the centralized control center 4 are connected in turn, the control unit 1 is connected to the base station 2 through RS485, and the base station 2 is connected through a wired optical fiber Connect with the centralized control center 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com