Servo driver and servo parameter operation method

A technology of servo drive and operation method, applied in the field of servo drive, can solve the problems of increasing manual operation links, loss of servo parameters, reducing reliability of servo drive, etc., shortening maintenance time, reducing maintenance cost, and simplifying the servo parameter setting process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention is specifically described as follows in conjunction with specific embodiments:

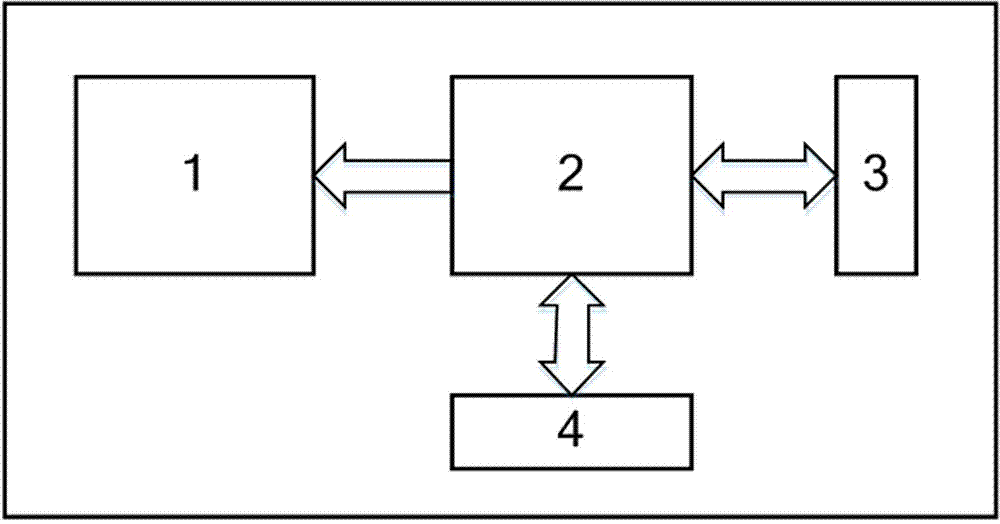

[0031] figure 1 It is a typical internal structure of the servo driver of the present invention, including: a drive control module 1, a servo parameter management module 2, an external data interface module 3 and an internal memory 4, wherein the drive control module 1 is directly connected to the servo parameter management module 2, and the servo parameter The management module 2 is directly connected to the external data interface module 3 and the internal memory 4 respectively.

[0032] The drive control module 1, as the core unit of the servo drive, completes the motor control function.

[0033] The servo parameter management module 2 performs unified operation and management on the servo parameters. On the one hand, the servo parameter management module 2 can directly operate the internal memory 4; on the other hand, through the external data inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com