Gear machining monitoring device

A monitoring device and gear technology, applied in the direction of comprehensive factory control, sustainable manufacturing/processing, program control, etc., can solve the problems of inability to monitor, manage and monitor secondary processing, waste raw materials, energy, and increase production cost input, and achieve savings. The effect of energy consumption, improving efficiency and reducing production cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

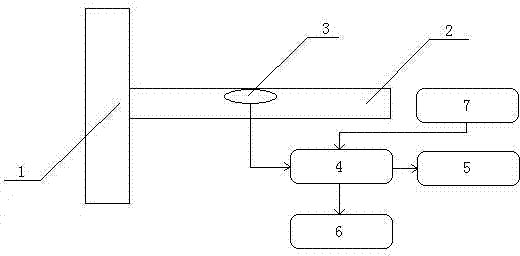

[0020] When in use, first place the gear blank on the positioning frame 1 to set the positioning shaft 2, turn on the power supply for power supply, and after initialization, the sensor module 3 transmits the information collected by induction to the CPU information processing module 4; the CPU information processing module 4 will receive The information is processed and displayed by the display module 5, wherein the data information taken by the CPU information processing module 4 to receive the video module 7 is also displayed by the display module 3; Prompt through the early warning module 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com