Special transformer coil winding device

A special transformer and winding technology, applied in coil manufacturing, inductor/transformer/magnet manufacturing, transportation and packaging, etc., can solve the problems of poor consistency of coil technical parameters, low production cost, unstable technical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

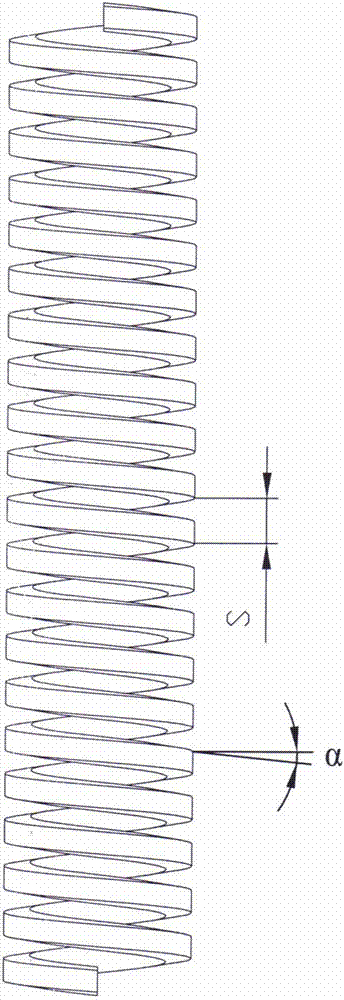

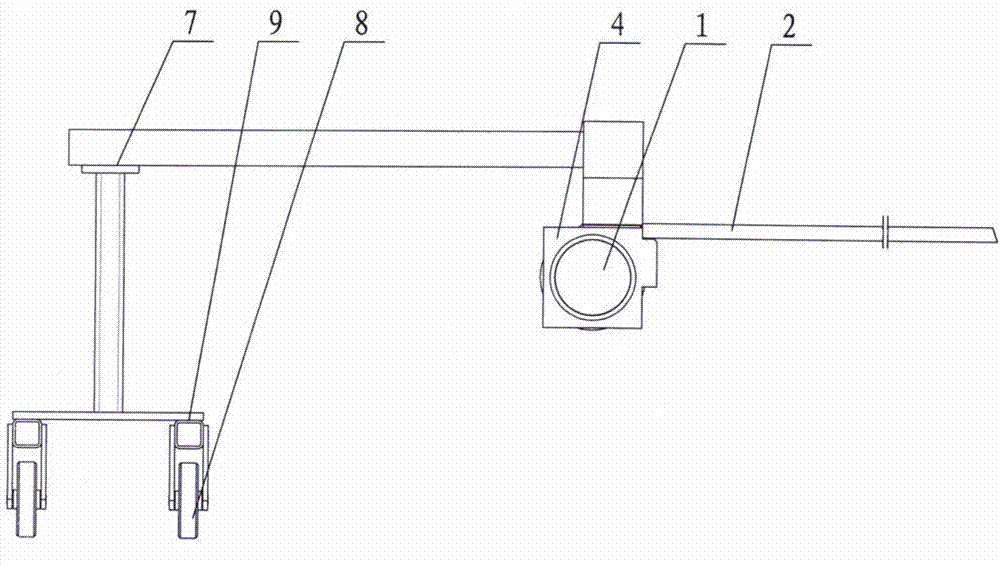

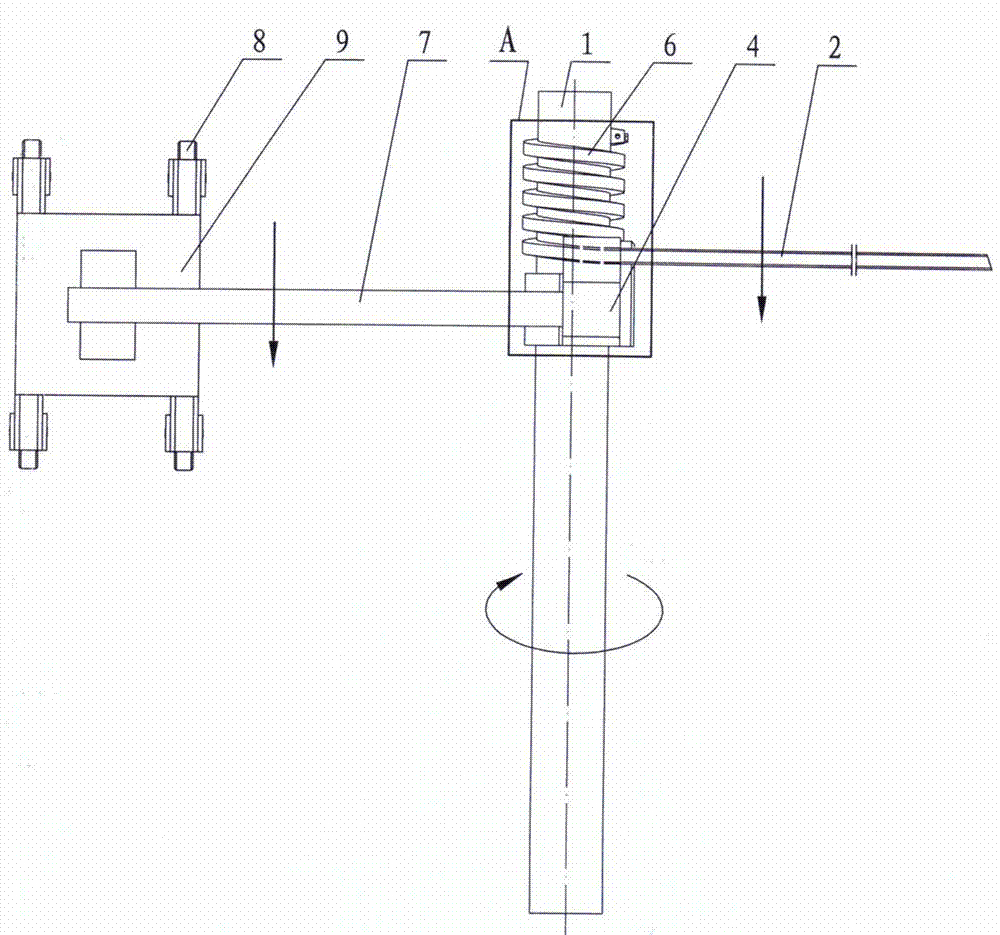

[0017] Figure 1 to Figure 7 It is a schematic diagram of the structure of the special transformer trapezoidal coil winding device. As can be seen from the figure, it includes a horizontally arranged rotating mandrel 1, and a screw 3 for fixing the head of the wound copper wire 2 is provided on the outer circular surface of the front end of the mandrel 1, such as Figure 4 , Figure 5 shown. The mandrel 1 is covered with a forming block 4 that guides the wound copper wire 2 to wind on the mandrel 1 and moves axially along the mandrel 1. The forming block 4 is provided with a copper opening that opens to the mandrel 1. The arc-shaped guide groove 5 of the wire 2, the helix angle α formed by the guide groove 5 and the mandrel 1 is equal to the helix angle of the wound coil 6, the rear side of the guide groove 5 corresponds to the front surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com