Asynchronous motor

A technology of asynchronous motor and motor shaft, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems that traditional motors cannot meet, difficult to operate, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

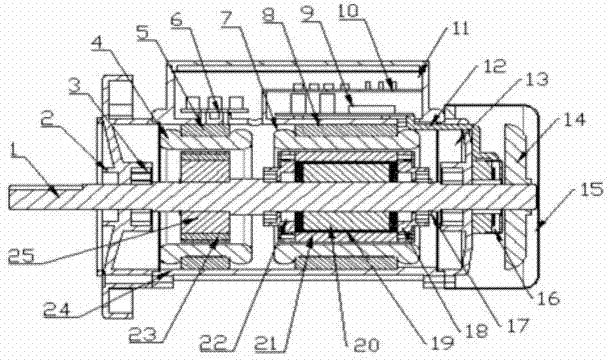

[0029] The invention consists of a motor shaft, a front end cover, a main bearing, a control coil, an auxiliary stator, a strong current terminal, a power coil, a main stator, a driving circuit board, an integrated control board, a wiring control box, a frequency shielding cable, a rear end cover, and a fan. , Rear wind cover, grating encoder, rotor bearing, rotor end cover, phase change magnetic material, main inner rotor, main outer rotor, skeleton oil seal, permanent magnet strip, motor casing, auxiliary rotor and other corresponding spare parts to form the whole machine product.

[0030] The invention includes a stator and a roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com