Steel pipe inseam welding machine

A seam welding machine and steel pipe technology, applied in the mechanical field, can solve problems such as welding inconvenience, and achieve the effect of improving work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

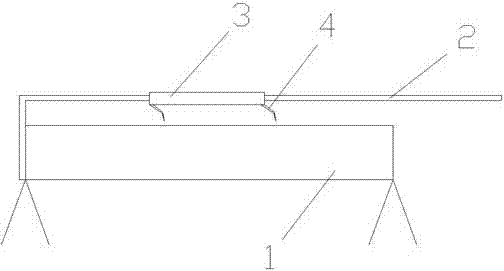

[0013] Such as figure 1 As shown, the steel pipe inner seam welding machine includes a base 1, and a bracket 2 is provided at one end of the base 1. The bracket 2 starts to go up vertically, and then bends and extends horizontally along the length direction of the base 1; the level of the bracket 2 An automatic sliding seat 3 is provided on the section, and the length of the sliding seat 3 is greater than or equal to 50 cm, and is driven by a motor, and a downward welding torch 4 is provided at both ends thereof. The length of the sliding seat (3) is greater than or equal to 50CM. The length of the base 1 plus the length of the sliding seat 3 is equal to the length of the horizontal section of the support 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com