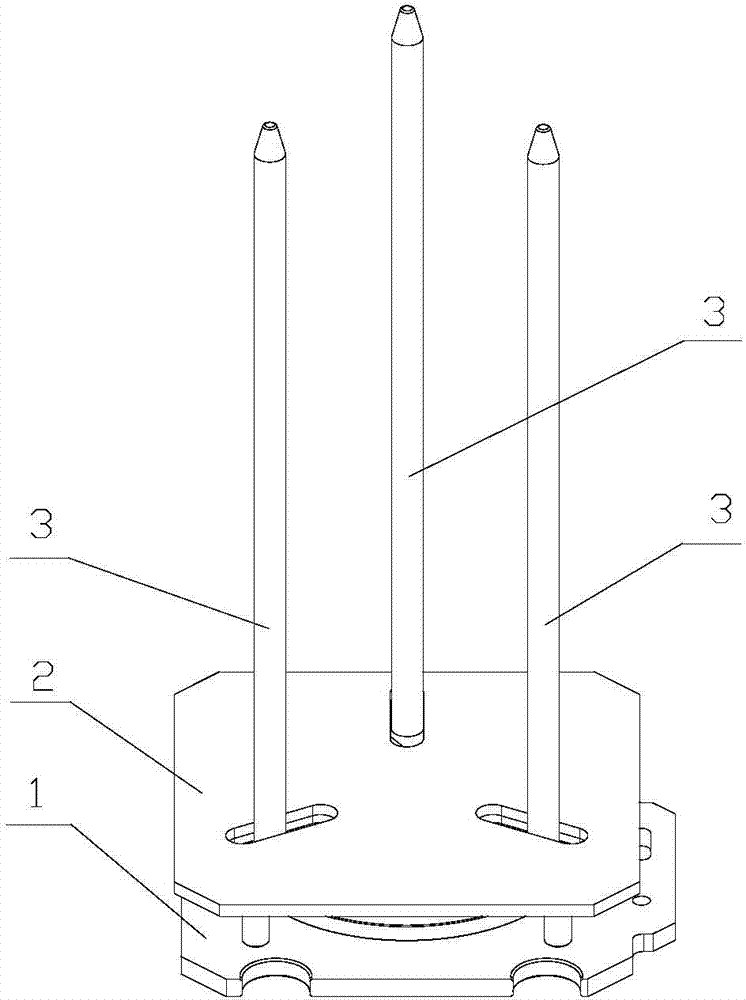

Material platform mechanism

A material table and platform technology, applied in the field of adjustable material table mechanism, can solve the problems of a certain cost of gear processing, complex structure, large overall quality, etc., to achieve enhanced centering and reliability, flexible structure operation, simple and flexible structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

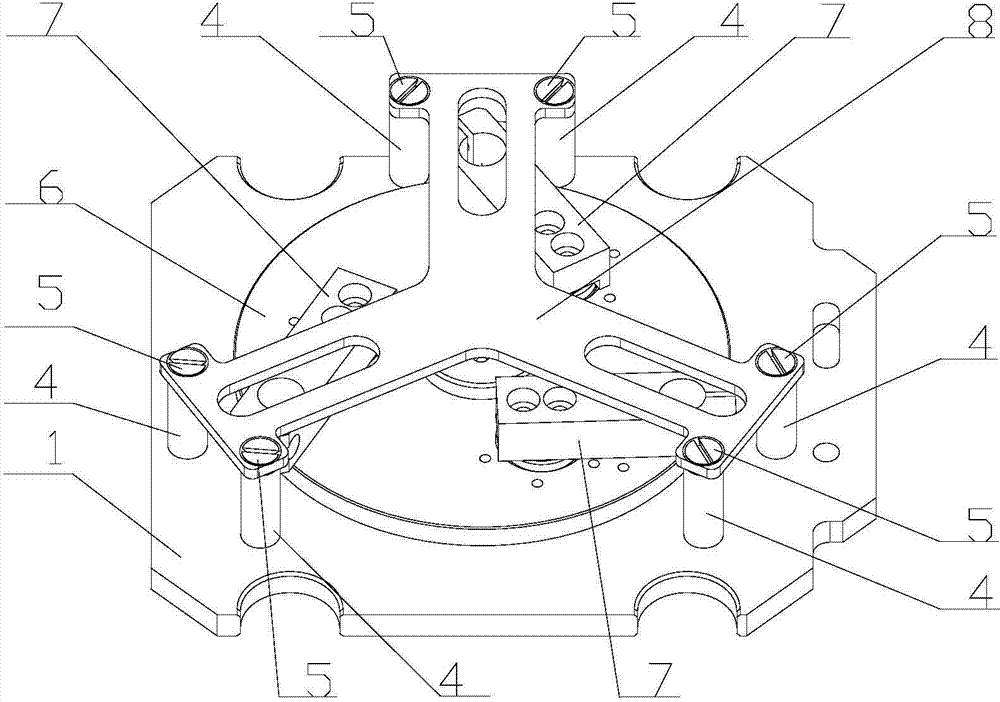

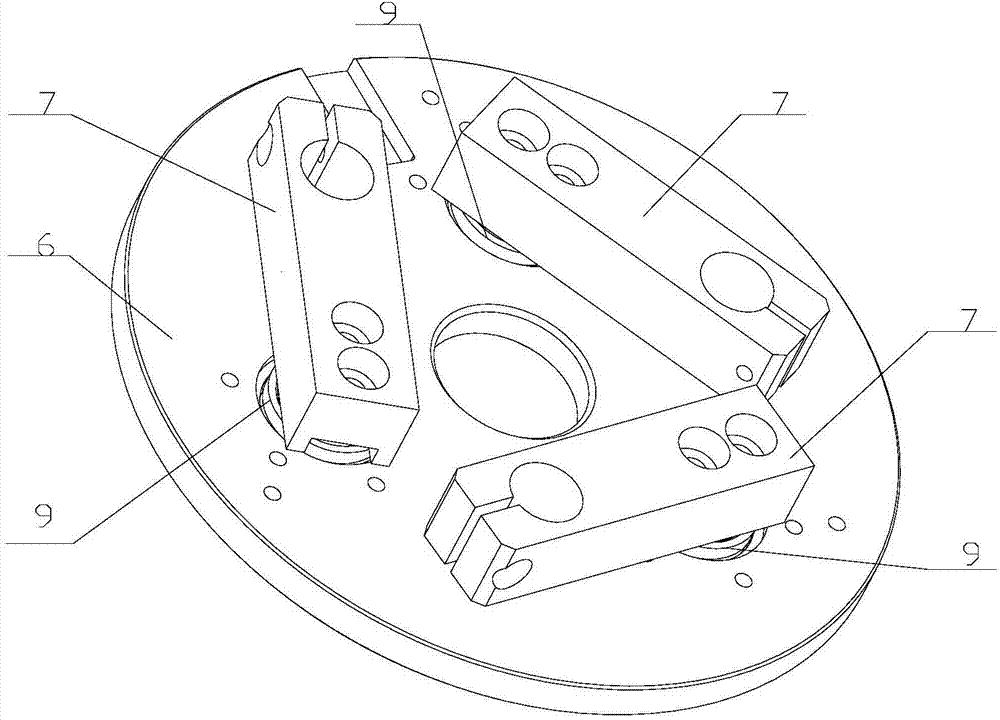

[0026] Aiming at the foundation of the current existing gear-type adjustable material table structure, according to its shortcomings, the purpose is to improve its performance, increase its operational flexibility, and reduce its processing cost. In terms of structure, it adopts a flexible and compact design, ignores the existing planetary gear structure, and uses a simple structure in which the centering platform drives the centering guide rod clamping block to realize the clamping and releasing of materials.

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] In the description of the present invention, the orientation or positional relationship indicated by the terms "inner", "outer", "longitudinal", "transverse", "upper", "lower", "top", "bottom" etc. are based on the drawings The orientations or positional relationships shown are only for the convenience of describing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com