Hydraulic clamp on-off reverse torque device and adjustment method thereof

A technology of hydraulic tongs and anti-torque, which is applied in the field of workover machinery used in oil fields, to achieve the effects of low failure rate, elimination of safety hazards, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

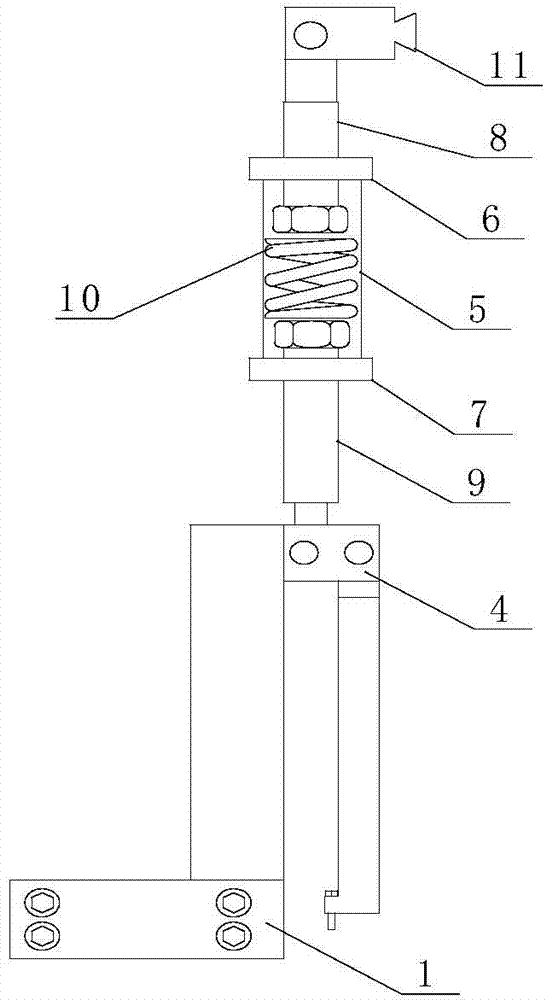

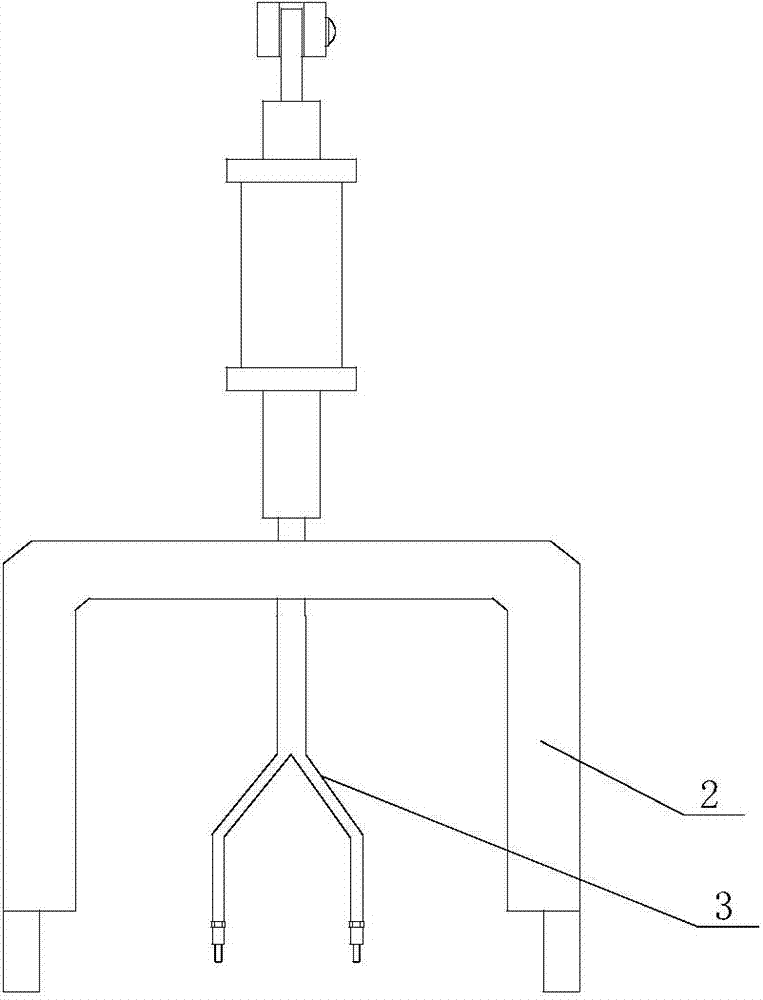

[0014] Example 1: Such as figure 1 with figure 2 As shown in the figure, a hydraulic pliers upper and lower unloading anti-torque device, the fixing frame 1 is two steel plates bolted to the two sides of the hydraulic pliers body, and the clamping hydraulic pliers are connected with the inverted U-shaped torque frame 2 by bolts, which can be suspended The role of lifting hydraulic tongs. The inverted U-shaped torsion frame 2 has a hole in the middle of the beam to connect with the gimbal beam 4; the inverted Y-shaped gimbal 3 has pin holes at the top of the two forks, and is connected to the two ear holes on the plane of the hydraulic clamp body. , The inverted Y-shaped balance frame 3 has two forks on the top side of the protruding side and opening holes, and adjusting screws are installed to adjust the overall balance of the hydraulic clamp. The upper top end of the inverted Y-shaped gimbal 3 is processed with pin holes to connect with the gimbal beam 4; the middle of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com