Expansion joint of multi-way pipeline

A technology for expansion joints and pipelines, which is applied in the direction of pipes/pipe joints/pipes, pipes, branch pipelines, etc., which can solve the problems of inconvenient connection, difficulty in splicing multi-branch parallel pipeline systems, and inconvenient changes in branch lengths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

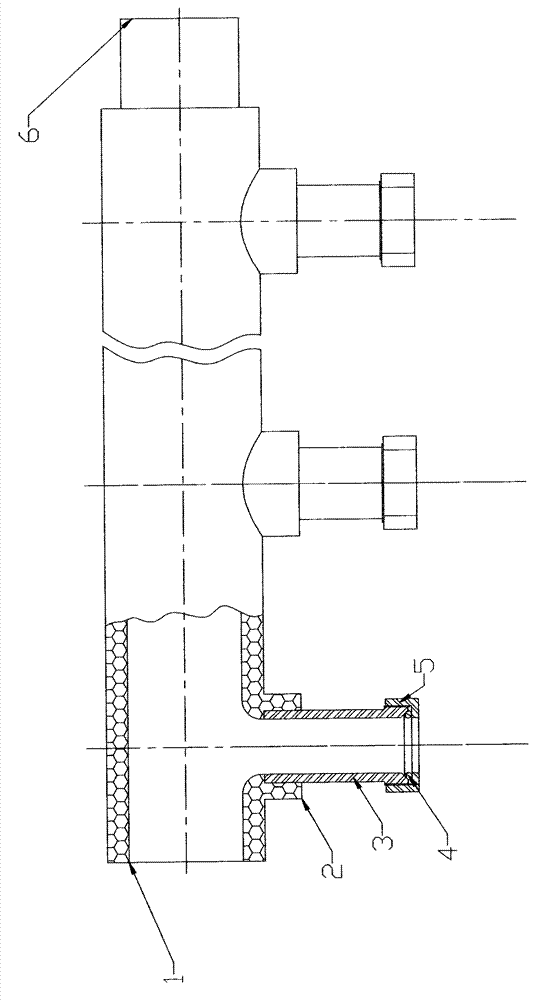

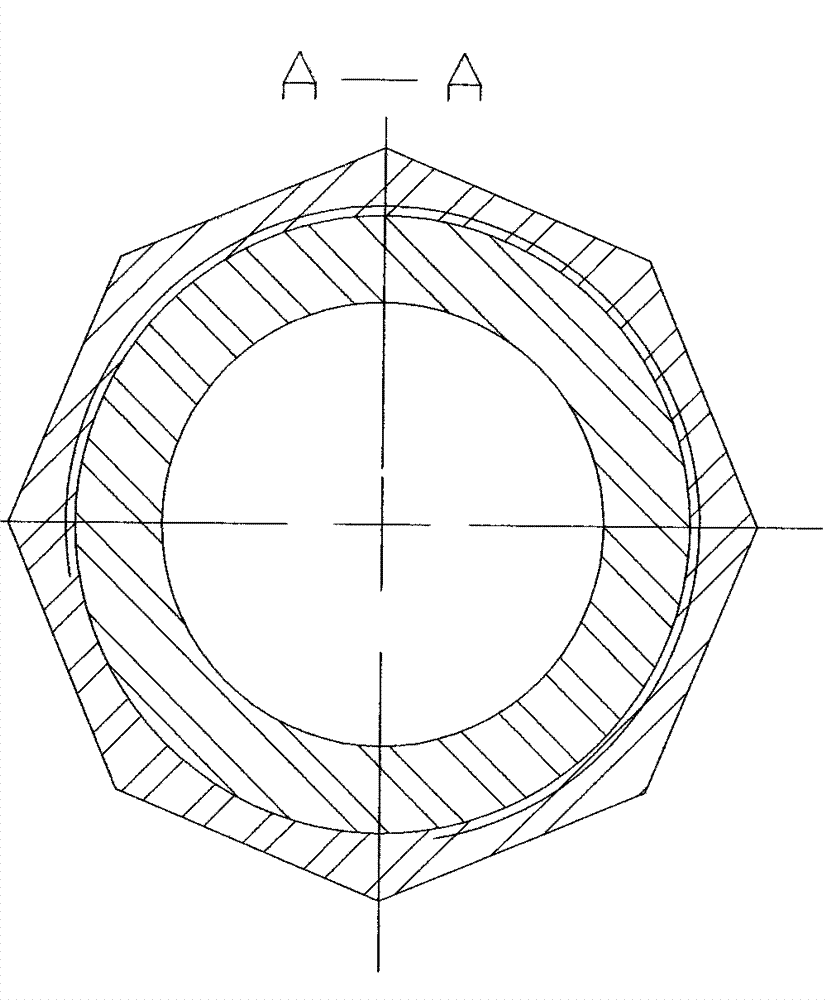

[0020] Figure 4 Among them, the parallel pipeline system is composed of two multi-way pipe expansion joints with inner wire extruded cover rings and 7 stainless steel pipes. The multi-way pipe expansion joints with inner wire extruded cover rings are provided with 7 branch pipes. The two ends of the pipe pass through the inner wire extruded cover ring 5 and the sealing ring 4 in sequence respectively, and are inserted into the outer wire expansion joint body 3, and the inner wire extruded cover ring 5 is tightened, and the inner wire extruded cover ring 5 and the outer The extrusion of the wire expansion joint body 3 makes the sealing ring 4 closely connected with the outer wire expansion joint body 3 .

Embodiment 2

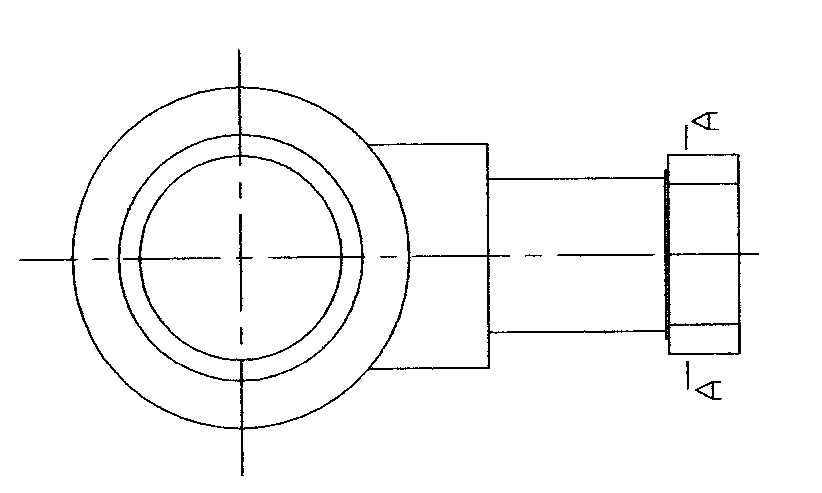

[0022] Figure 7 Among them, a parallel pipeline system is composed of two multi-way pipe expansion joints extruded by outer wires and 8 stainless steel pipes. The inner wire expansion joint body 9 is provided with 8 branch pipes, and the two ends of the stainless steel pipes are in turn Correspondingly pass through the outer wire extrusion cover ring 11 and the sealing ring 10, and insert it into the inner wire expansion joint body 9, tighten the outer wire extrusion cover ring 11, and pass the outer wire extrusion cover ring 11 and the inner wire expansion joint body 9 Squeeze, so that the sealing ring 10 is closely connected with the inner wire expansion joint body 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com