Digital dimple depth gauge

A depth measuring instrument and depth measurement technology, applied in the field of measurement, can solve the problems of low work efficiency, time-consuming and laborious, and rely on manual reading, etc., and achieve the effects of easy portability, intuitive and convenient reading, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of the accompanying drawings.

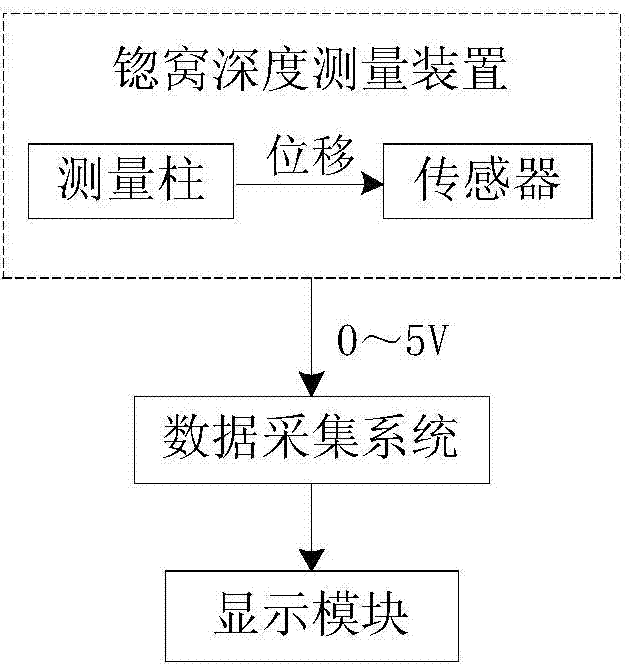

[0029] see figure 1 , The countersink depth measuring instrument of the present invention transmits the displacement information to the displacement sensor through its internal measuring column, and the sensor converts the displacement signal into an analog electrical signal, which is processed by the data acquisition system and displays the result on the display terminal.

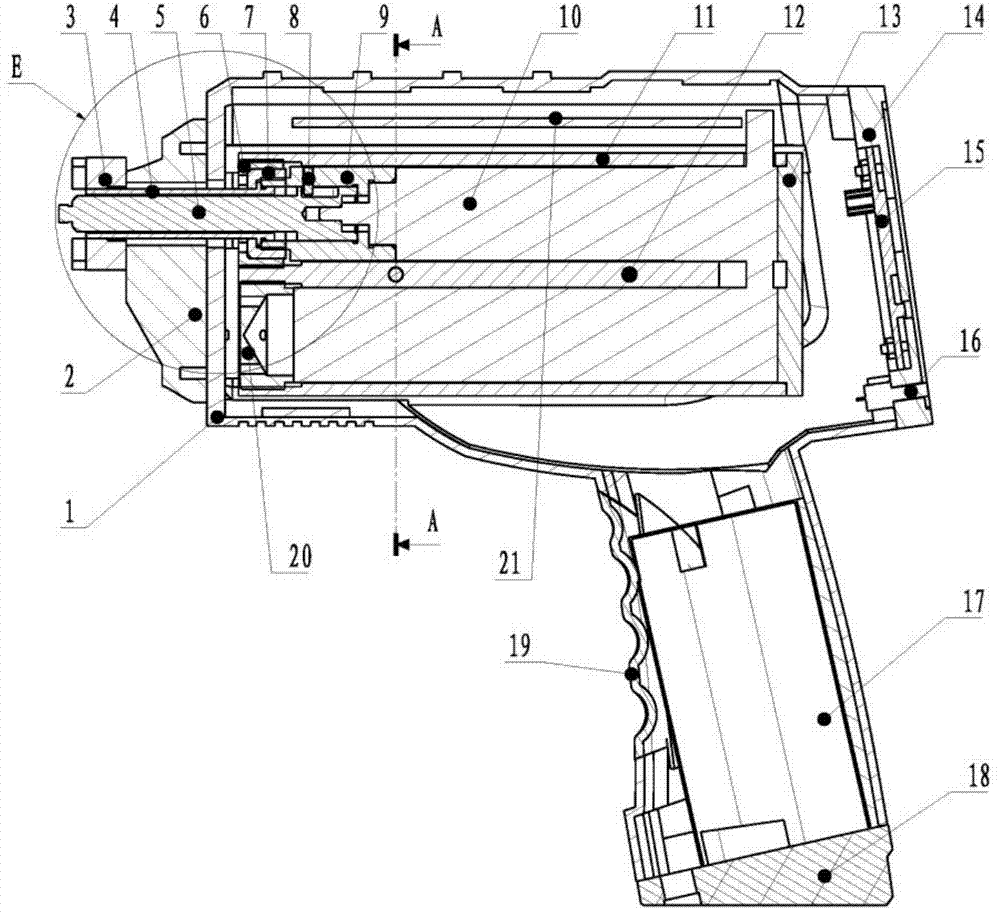

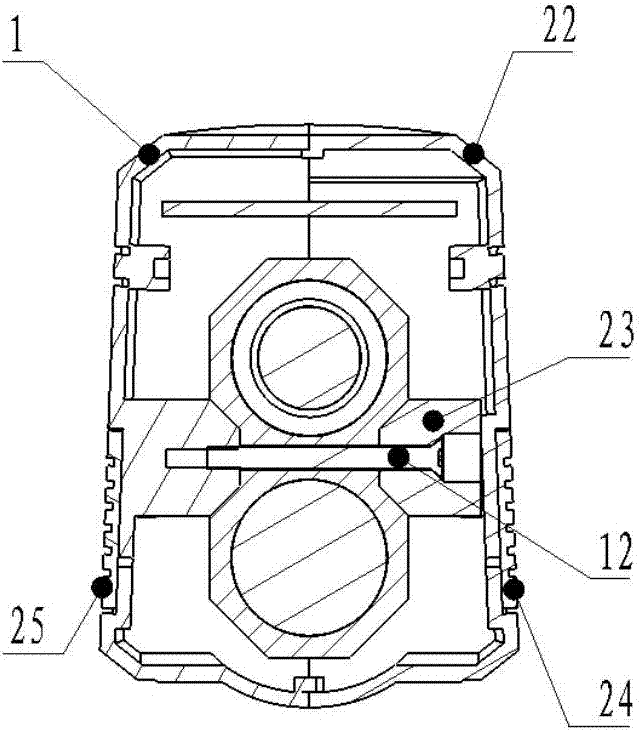

[0030] see figure 2 , image 3 , The countersink depth measuring instrument of the present invention includes: the left half shell 1 of the measuring instrument, the lower cover 2 of the measuring instrument, the feet 3, the sleeve 4, the measuring column 5, the large gland I6, the small gland 7, the guide column 8, and the measuring sleeve 9. Displacement sensor 10, measuring module shell 11, screw 12, measuring module back cover 13, measuring instrument cover 14, display module 15, power sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com