High-precision calibration method and device for optical dissolved oxygen sensor

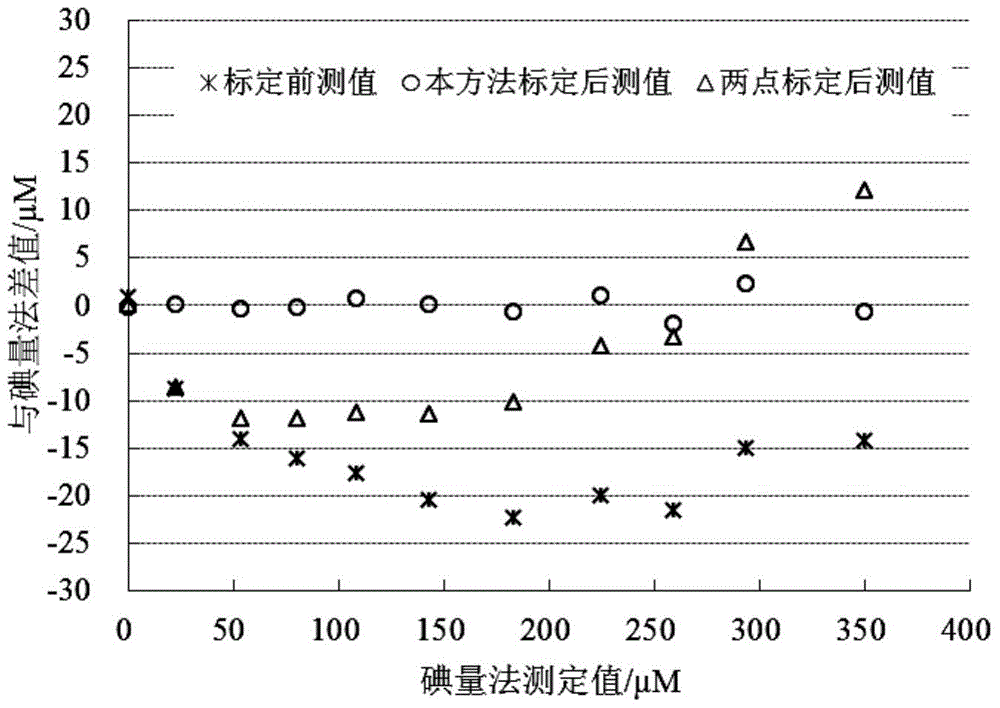

A technology of dissolved oxygen sensor and calibration method, which is applied in the field of high-precision calibration of optical dissolved oxygen sensors, can solve the problems of few calibration points, inaccurate standard values, limited application range of calibration results, etc., and achieves wide temperature application range and reference value accuracy. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

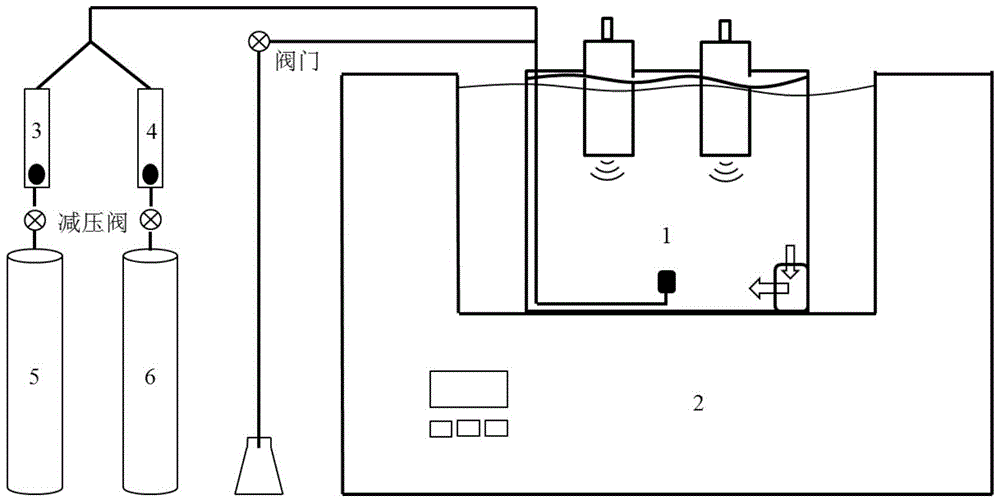

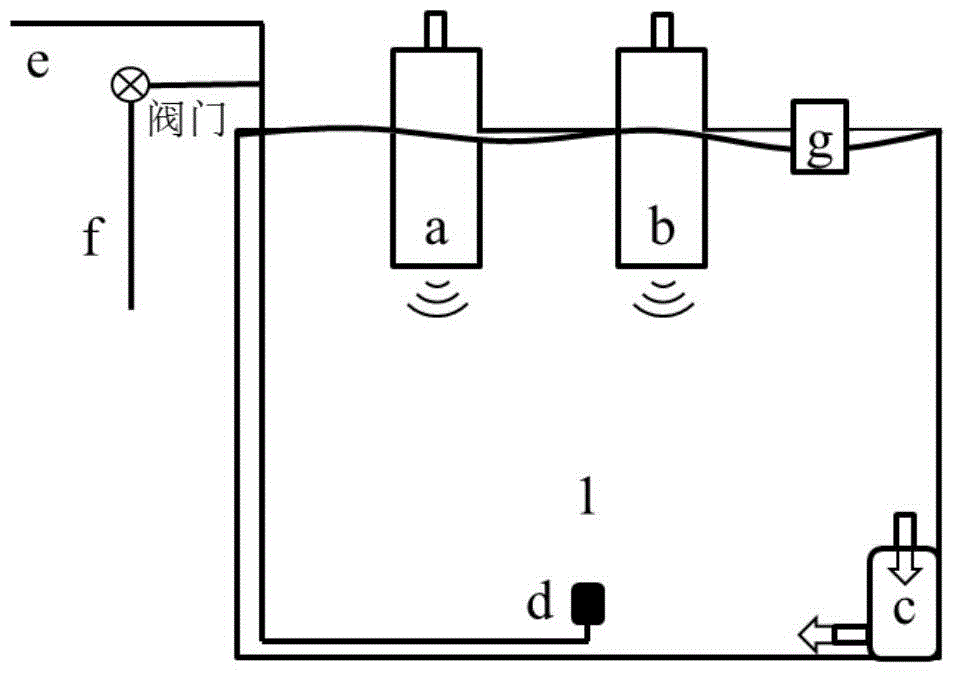

[0034] like figure 2 and image 3 As shown, the calibration device of the optical dissolved oxygen sensor in the present invention comprises a water-gas mixer 1, a water bath 2 with a water temperature control device, a gas flow meter 3, a gas flow meter 4, an oxygen cylinder 5, a carrier gas cylinder 6 (built-in Inert carrier gas), reference dissolved oxygen sensor a, dissolved oxygen sensor to be calibrated b and stirrer c.

[0035] Among them, the water-gas mixer 1 is a cylindrical barrel made of a material with good thermal conductivity; a gas inlet e and a gas outlet g are reserved on the barrel wall, and the former is connected to the air blowing sand nozzle d to increase air bubbles and improve water-gas mixing. Efficiency, the latter is used as the gas outlet when the gas is blown, and it is closed after the gas blow is over, and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com