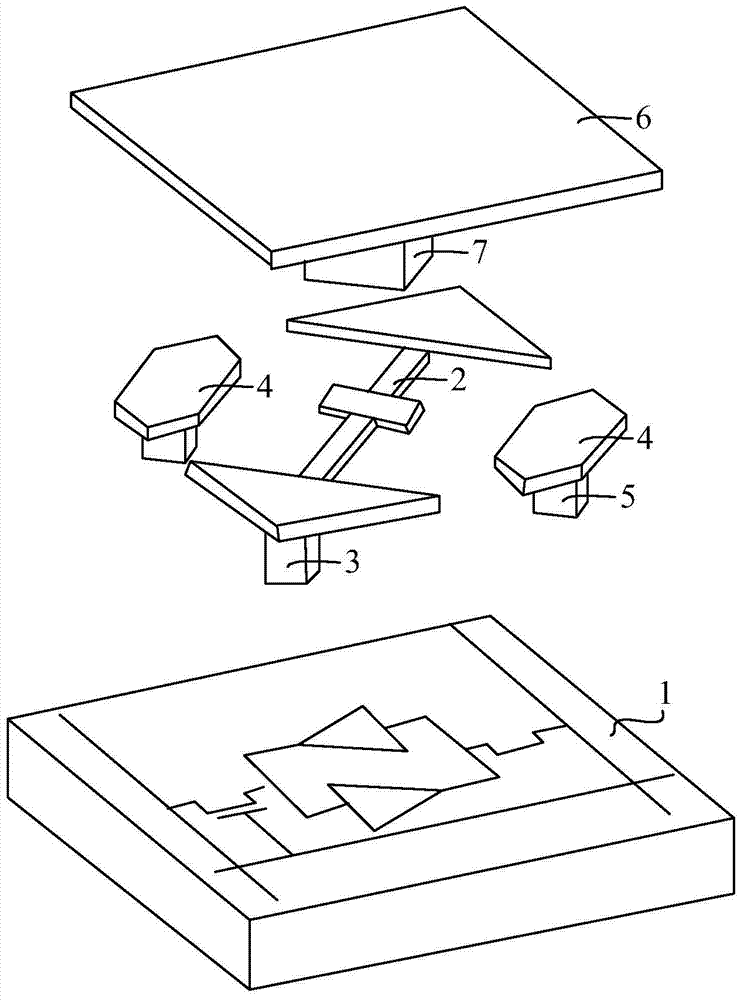

Formation method of digital micromirror device

A digital micromirror device and patterning technology, applied in instruments, optical components, optics, etc., can solve the problems of inability to remove the patterned photoresist layer, and the inability to remove the hinge patterned photoresist layer. Plasma damage, reduced time, improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

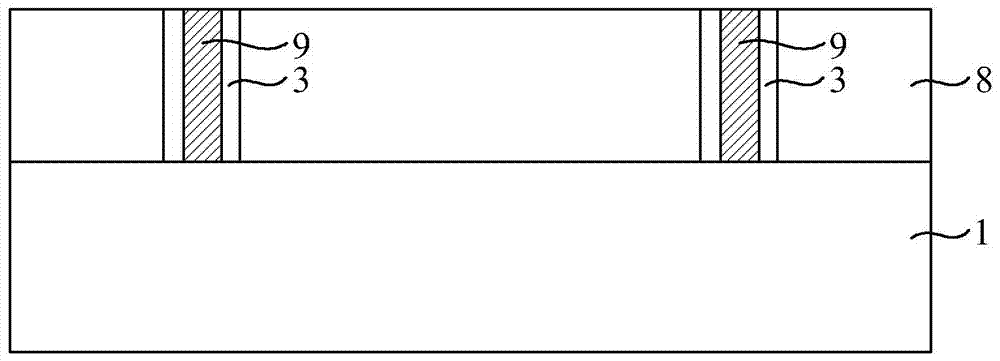

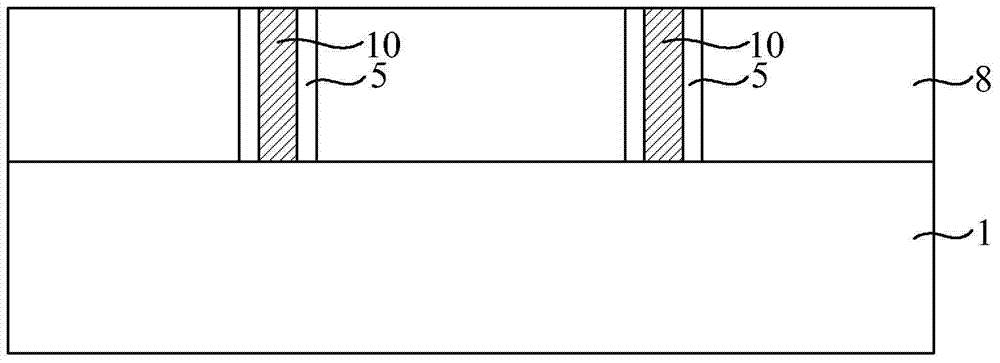

[0048] After research and analysis, it is found that the reason why the existing digital micromirror device formation method cannot remove the patterned photoresist layer above the hinge is: Figure 5A with Figure 5B As shown, the patterned photoresist layer 11 is used to protect the dielectric layer 22 in the hinge 2, so that the dielectric layer 22 will not be etched during the process of forming the hinge 2 by dry etching. In order to make the patterned photoresist layer 11 can play this role, it is necessary to ensure that the patterned photoresist layer 11 has sufficient thickness; Figure 6A with Figure 6B As shown, in the step of removing the patterned photoresist layer 11 by using the wet etching method, in order to enable the patterned photoresist layer 11 to be removed cleanly, it is necessary to ensure that the wet etching takes a long time, but in this way It will cause the two ends of the dielectric layer 22 in the hinge 2 to be corroded by the etchant. In ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com