High-efficiency transformer core slice inserting machine

A technology of transformer iron core and chip inserter, which is applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, electrical components, etc. problems, to achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

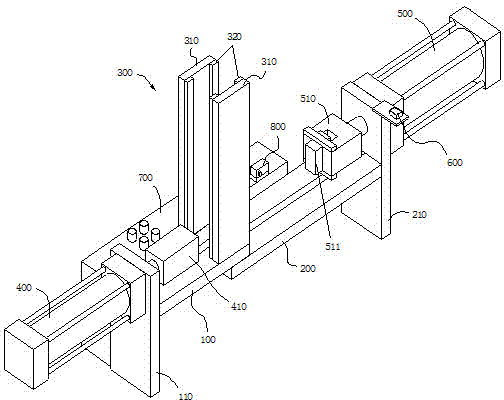

[0021] Attached below figure 1 A preferred embodiment of the present invention will be described in detail.

[0022] The present invention provides an inserting machine for stacking iron chips into an iron core and inserting the iron core into a transformer wire package, including an upper guide rail 100, a lower guide rail 200, a discharge chute 300, a first cylinder 400, and a second cylinder 500 , start switch 600 , electrical box 700 and limit switch 800 .

[0023] The two ends of the upper and lower guide rails are respectively horizontally fixed by the first cylinder frame 110 and the second cylinder frame 210, and the two front ends of the upper and lower guide rails are stacked up and down in dislocation. The first cylinder is horizontally arranged on the cylinder frame one, and the front end of the piston rod of the first cylinder is connected with a pushing block 410 for pushing the transformer iron core. The pushing block can move in translation along the upper gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com