Alkaline storage battery and production method of alkaline storage battery

A storage battery, alkaline technology, applied in the field of alkaline storage batteries, can solve the problems of high cycle life characteristics, poor rate discharge characteristics, low liquid retention of separators, difficulty in fully sulfonating fibers, etc., and achieve excellent capacity storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

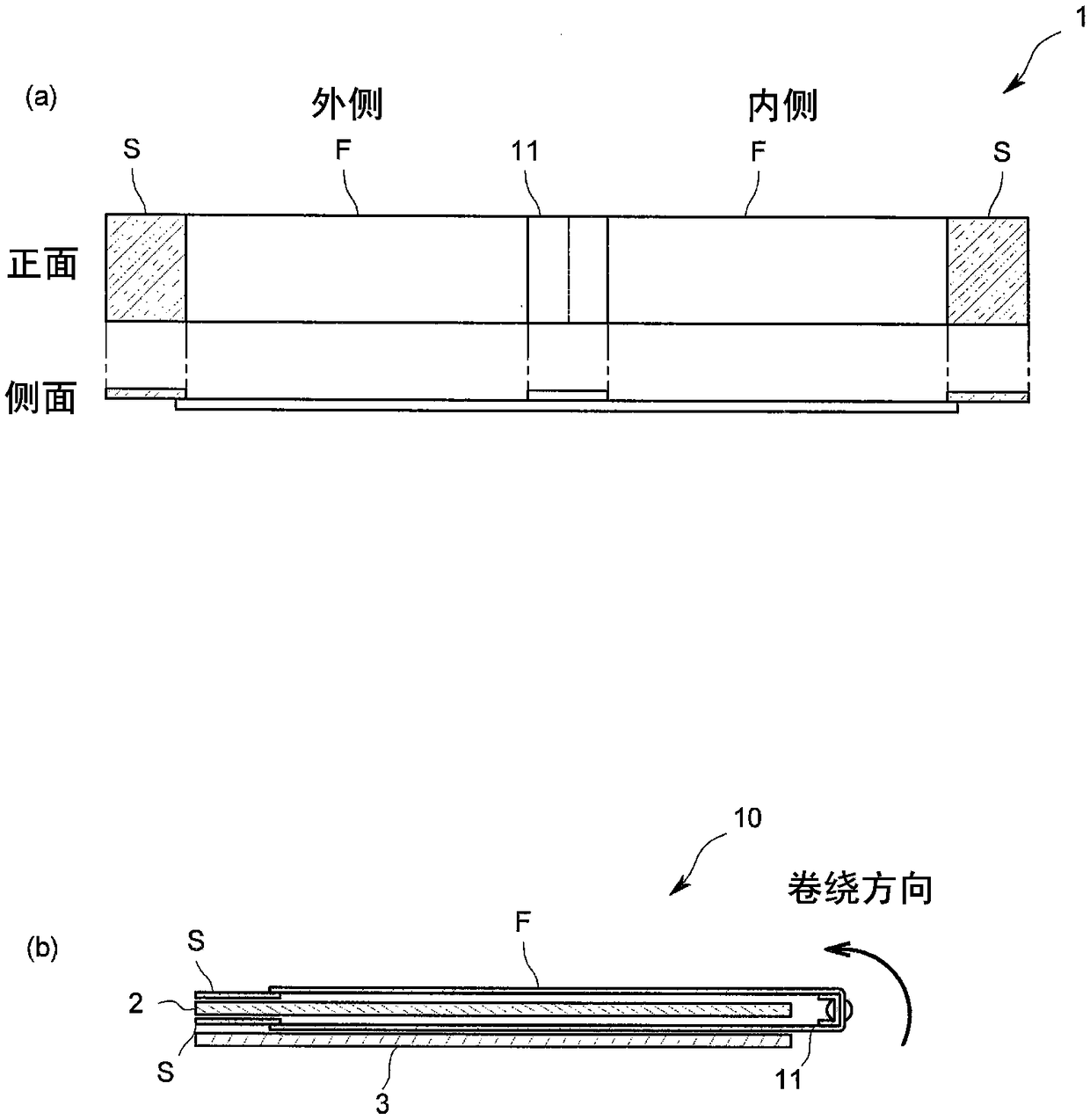

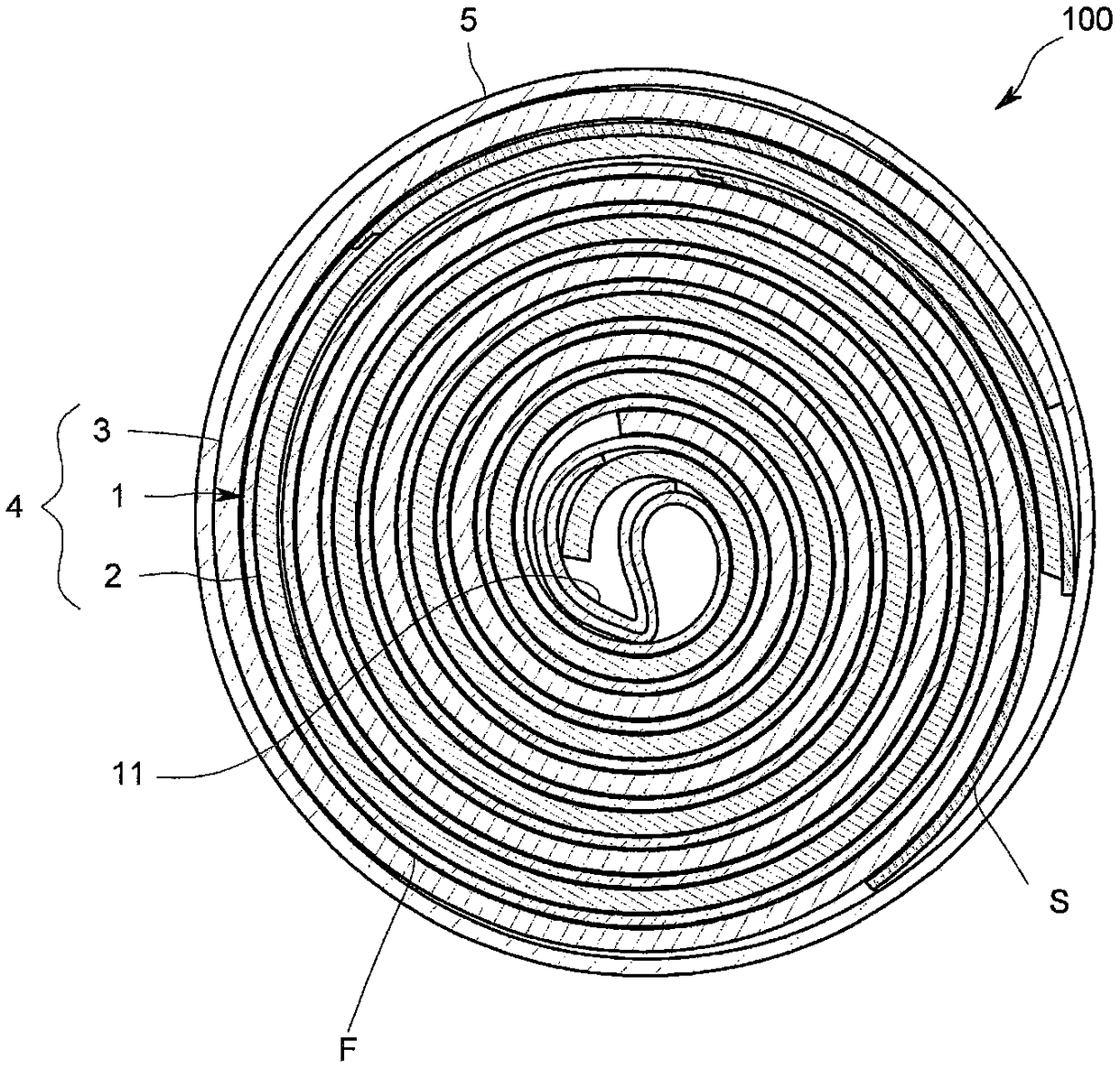

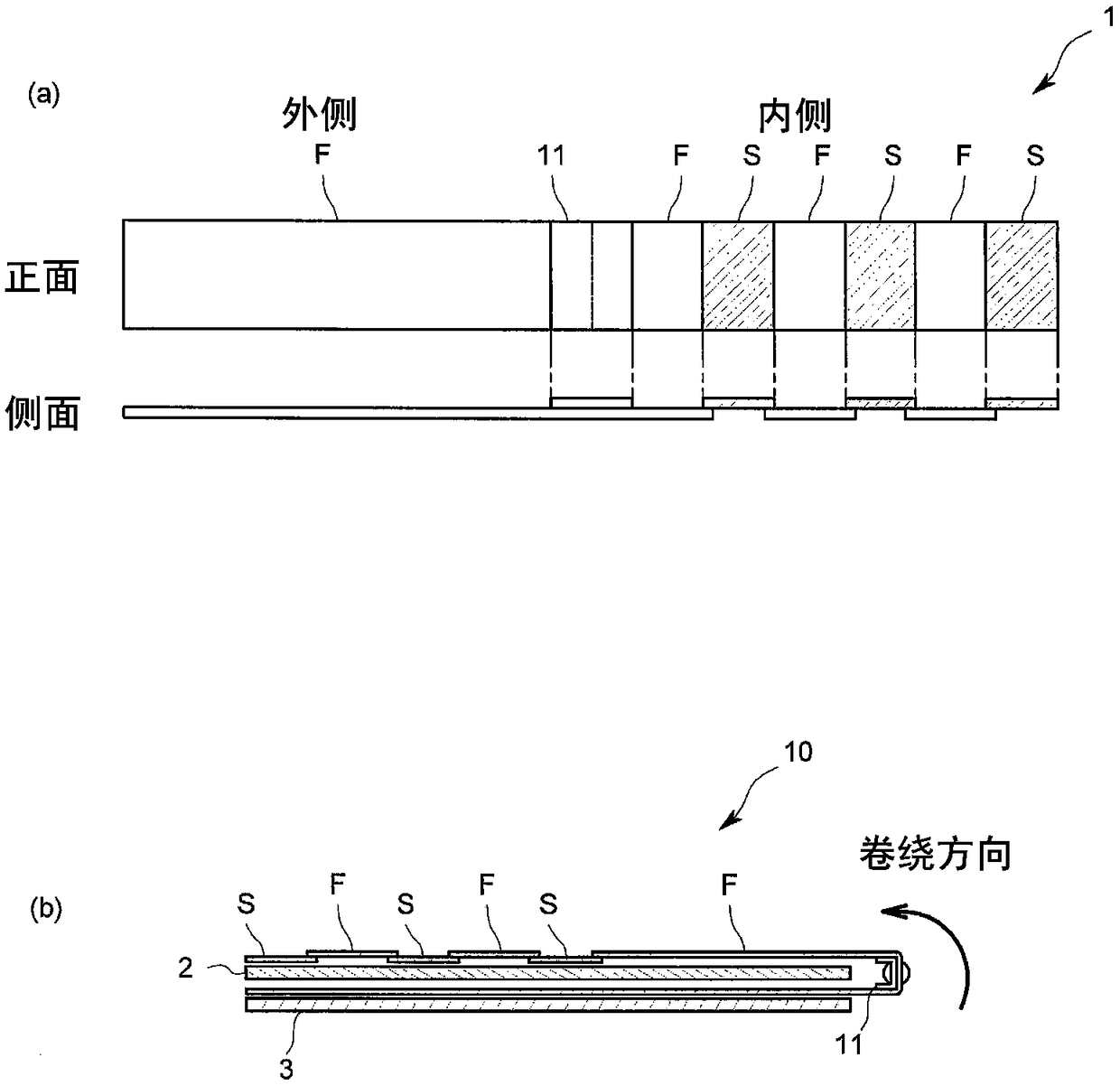

[0041] The present invention will be described in detail below.

[0042] The separator according to the present invention is composed of a long sheet.

[0043] Examples of the sheet-like article include nonwoven fabrics made of fibers made of polyolefin-based resins such as polyethylene-based resins and polypropylene-based resins. Although the nonwoven fabric can be produced by, for example, a dry method, a wet method, a spunbond method, a meltblown method, etc., it is preferably produced by a wet method from the viewpoint of compactness.

[0044] The separator according to the present invention has sulfo groups in a plurality of mutually separated regions of the sheet.

[0045] According to such a separator, the nitrogen-based impurities dissolved in the electrolytic solution can be efficiently captured by dispersing and forming domains having sulfo groups in the separator.

[0046] In the separator according to the present invention, sulfonic acid groups (—SO3H) are introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com