Telescopic three-dimensional seedling growing frame

A technology for erecting seedlings and seedling racks, which is applied to the field of cultivation containers, can solve the problems of damaging seedling trays, increasing seedlings, affecting convenience, etc., and achieves the effects of easy disassembly and assembly, soil increase and decrease, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

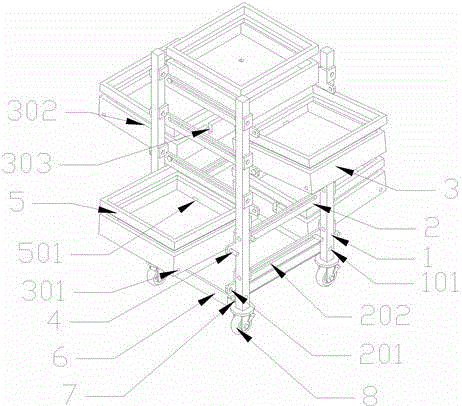

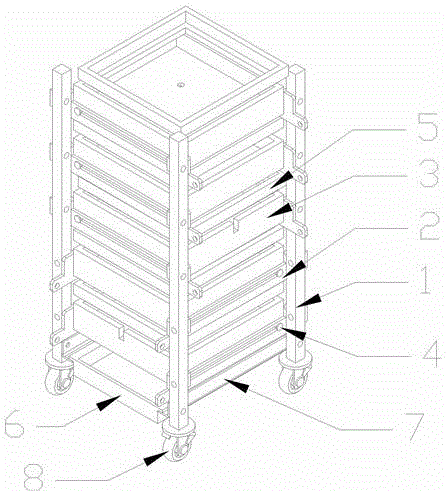

[0030] like Figures 1 to 5 As shown, a telescopic three-dimensional seedling stand includes a support foot 1 , a support plate 2 connected to the support foot 1 , and a supporting plate 3 arranged on the support plate 2 . Described support foot 1 is provided with screw hole 101, and the bottom end of support foot 1 is provided with pulley 8, and described pulley 8 has functions such as turning, braking, is convenient to mobile seedling raising frame.

[0031] The length of the support plate 2 is the distance between the two legs 1 connected to it, the two ends of the support plate 2 are provided with holes 201, and the middle is provided with a rectangular chute 202 with rounded corners; the support plate 2 passes through the screw holes 101 and The legs 1 are connected, and the fixed position of the supporting plate 3 and the supporting legs 1 can be adjusted according to the growth needs of the plants, thereby adjusting the distance between the upper and lower supporting pl...

Embodiment 2

[0037] The seedling raising frame structure of embodiment 2 is similar to that of embodiment 1, only the structure of supporting plate 3 is different. like Image 6 As shown, there are side plates 302 on the upper parts of the two sides parallel to the support plate 2 in the supporting plate 3, and there are no side plates 302 on the other two sides, and no drainage outlet 303 is provided, which is beneficial to processing and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com