Capsule drying and polishing all-in-one machine

An all-in-one machine and capsule technology, which is used in capsule delivery, drug delivery, and pharmaceutical formulations. It can solve the problems of large space occupied by the machine, increase the production cost of capsules, and low efficiency. It is easy to operate, easy to maintain, and reduces labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

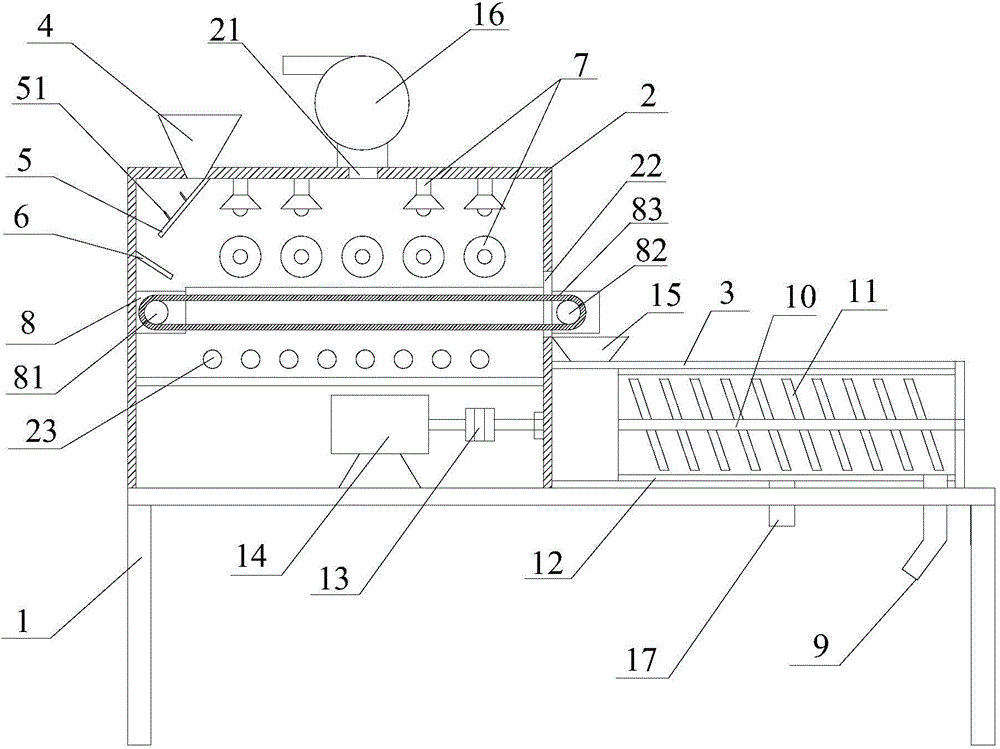

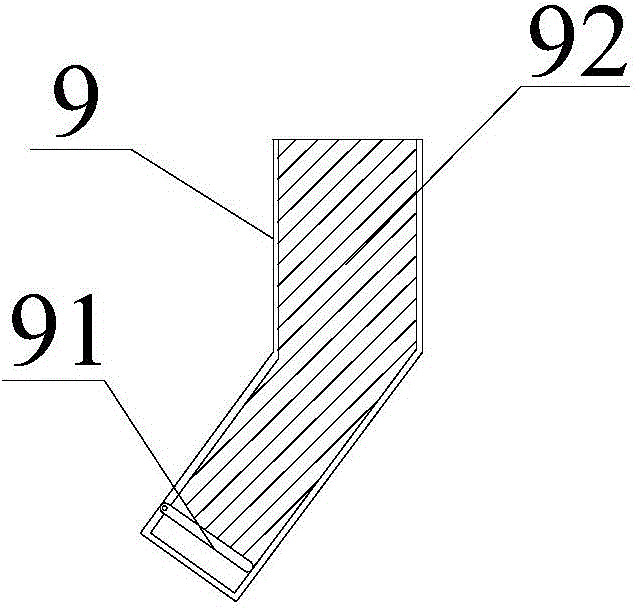

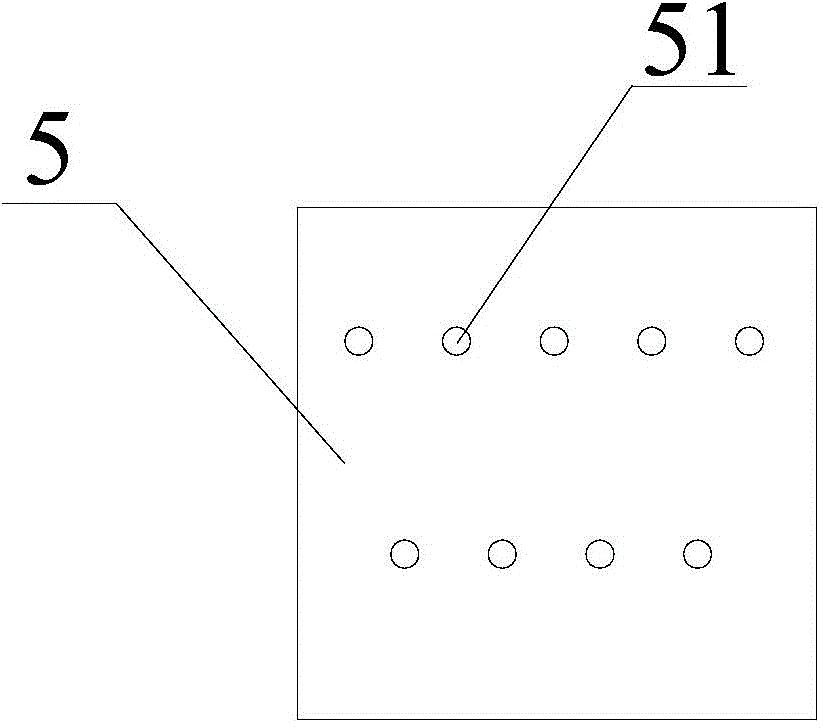

[0017] refer to figure 1 , figure 2 with image 3 , a capsule drying and polishing machine according to the present invention, comprising a workbench 1, a drying body 2, and a polishing body 3, the drying body 2 is installed above the workbench 1, and the polishing body 3 is installed above the workbench 1 , the drying machine body 2 and the polishing machine body 3 are connected as a whole, and the drying machine body 2 is composed of a first feeding hopper 4, a first baffle plate 5, a second baffle plate 6, an illuminating lamp 7, a transmission device 8 and a draft Machine 16, the first hopper 4 is installed above the dryer body 2, the first baffle 5 is installed inside the dryer body 2, and the second baffle 6 is installed inside the dryer body 2, so A transmission device 8 is installed in the dryer body 2, a conveyor belt 83 is installed on the transmission device 8, an air exhaust port 21 is provided on the dryer body 2, and an exhaust fan 16 is installed above the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com