3-thioglutaramide extractant and its application in palladium extraction

The technology of thioglutaramide and extraction agent is applied in the field of precious metal extraction, which can solve the problems of long extraction equilibrium time and acid insufficiency, and achieve the effects of superior extraction performance, low cost and good radiation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned 3-thioglutaramide class extraction agent comprises the steps:

[0029] (1) Preparation of dimethyl 2,2'-thiodiglycolic acid: Dissolve 2,2'-thiodiglycolic acid in methanol to obtain a methanol solution of 2,2'-thiodiglycolic acid, 2,2'- The material molar ratio of thiodiglycolic acid to methanol is 1:(2~3), heated and kept at 5~100°C, stirred for 3~15h, placed and cooled to room temperature, removed methanol by rotary evaporation, and then vacuumed to remove residual methanol to obtain crude 2,2'-dimethyl thiodiglycolate;

[0030] (2) Preparation of 2,2'-3-thioglutaramide: Prepare the chloroform solution of amine and the chloroform solution of dimethyl thiodiglycolate crude product respectively, and then dimethyl thiodiglycolate The chloroform solution of the crude product is added dropwise to the chloroform solution of the amine, the molar ratio of dimethyl 2,2'-thiodiglycolate to the amine is 1:(2~3), at 20~100℃ After the dro...

Embodiment 1

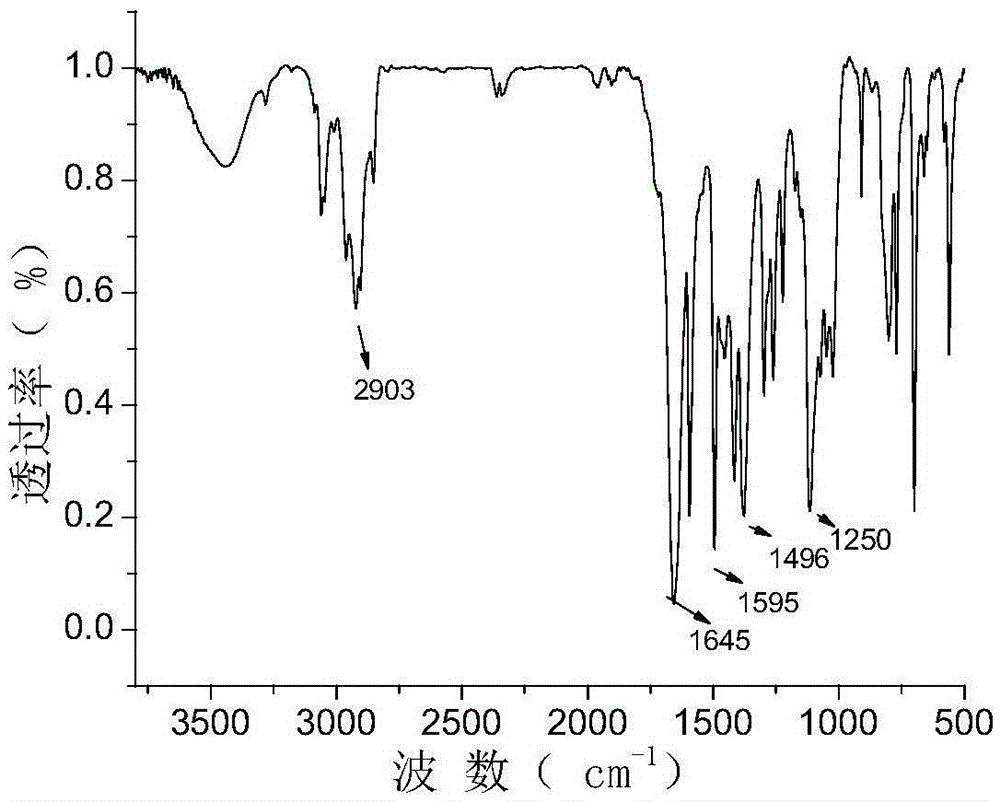

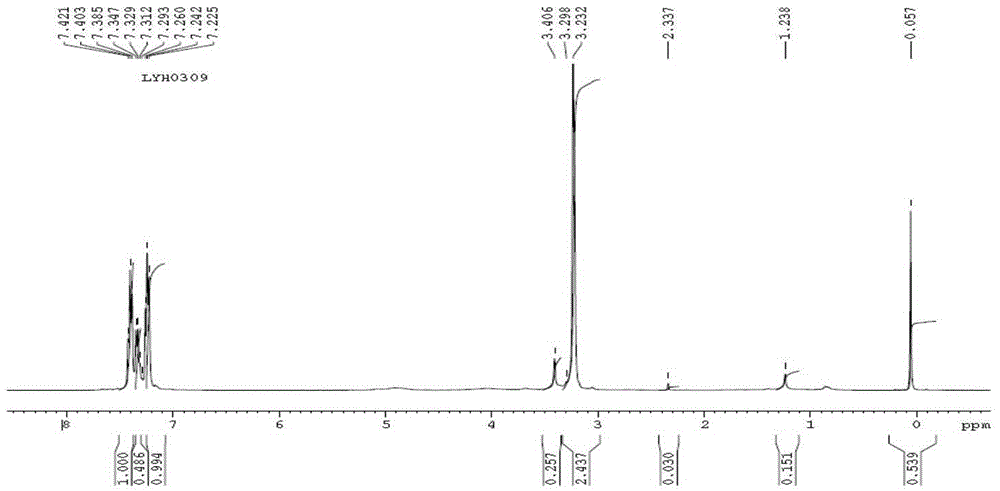

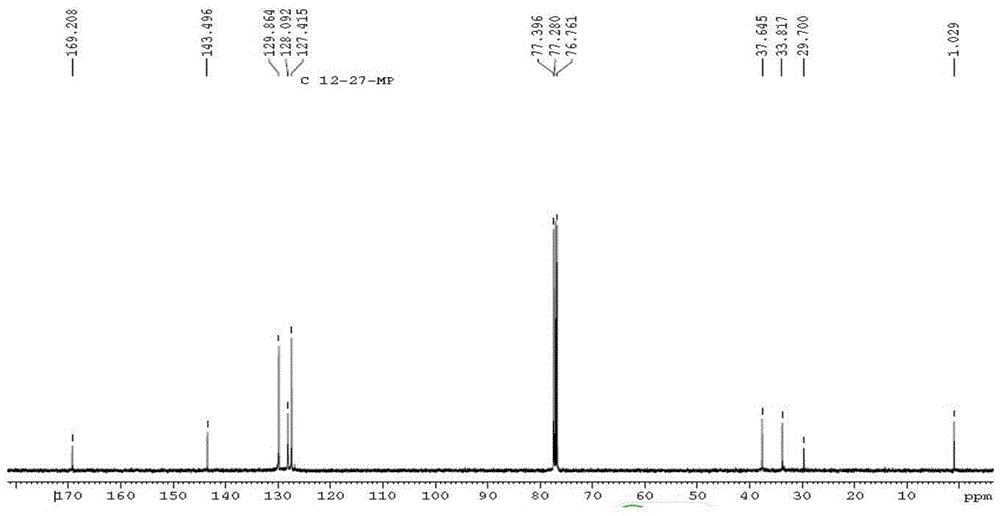

[0034]Example 1 Preparation of N, N'-dimethyl-N, N'-diphenyl-3-thioglutaramide.

[0035] Add 2,2'-thiodiglycic acid into a three-necked flask and dissolve it in methanol; stir and react at 50°C for 5 hours; let it cool to room temperature, transfer the reaction solution into an eggplant-shaped flask, and remove excess methanol with a rotary evaporator. Then, the residual methanol was removed by vacuum suction to obtain dimethyl 2,2'-thiodiglycolic acid with a yield of 85%.

[0036] Add methylaniline into a three-necked flask with a constant pressure funnel and dissolve it with chloroform, and dissolve dimethyl 2,2'-thiodiglycolic acid with chloroform and transfer it to a constant pressure funnel; place the three-necked flask at 40 In a water bath at ℃, drop thiodiglycolyl chloride in chloroform at a rate of 1 drop per second. After completion of the dropwise addition, the reaction was stirred at 140° C. for 3 hours.

[0037] Cool the obtained reaction solution to room temper...

Embodiment 2

[0049] Example 2 The test of the equilibration time of extractant extracting noble metal palladium.

[0050] The reaction product prepared in Example 1 is dissolved in the chloroform system, and the concentration of the extractant is formed as a chloroform solution of 0.02mol / L, and as the organic phase, the aqueous solution of palladium chloride is prepared so that the concentration of palladium is 50mg / L, as the aqueous phase, the extraction test was carried out. Among them, the volume of the organic phase and the aqueous phase are each 5 mL in the Erlenmeyer flask and oscillated in the constant temperature oscillator in the water bath until the extraction equilibrium is reached. During the extraction process, the concentration of hydrochloric acid is controlled at 3 mol / L, the amplitude is 160 ± 2 spm, and the extraction temperature is controlled at 25 ± 0.5 °C, after shaking, transfer to a centrifuge tube for centrifugal phase separation, and the metal ion concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com