Nano bubble generating device for gas-liquid or liquid-liquid mixture

A technology of nano-bubbles and generating devices, which is applied in the direction of mixers, mixing methods, fluid mixers, etc., can solve the problems of not being able to maintain the scope of application for a long time, low production efficiency of nano-bubble water, and low concentration of nano-bubble water. Simple structure, small footprint, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

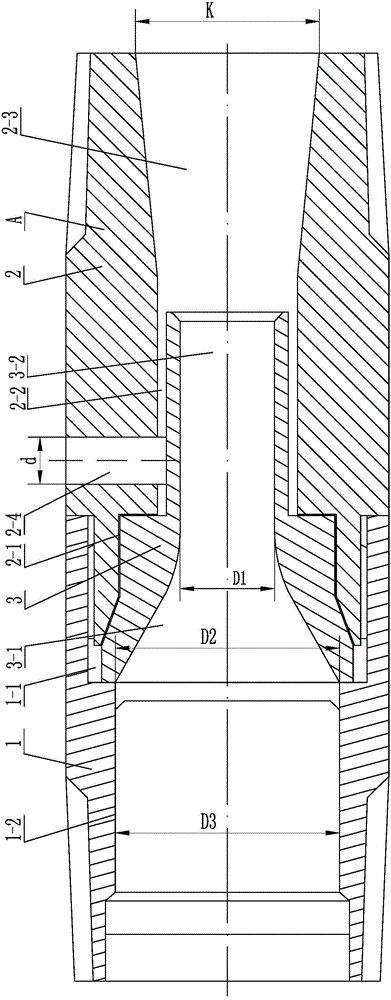

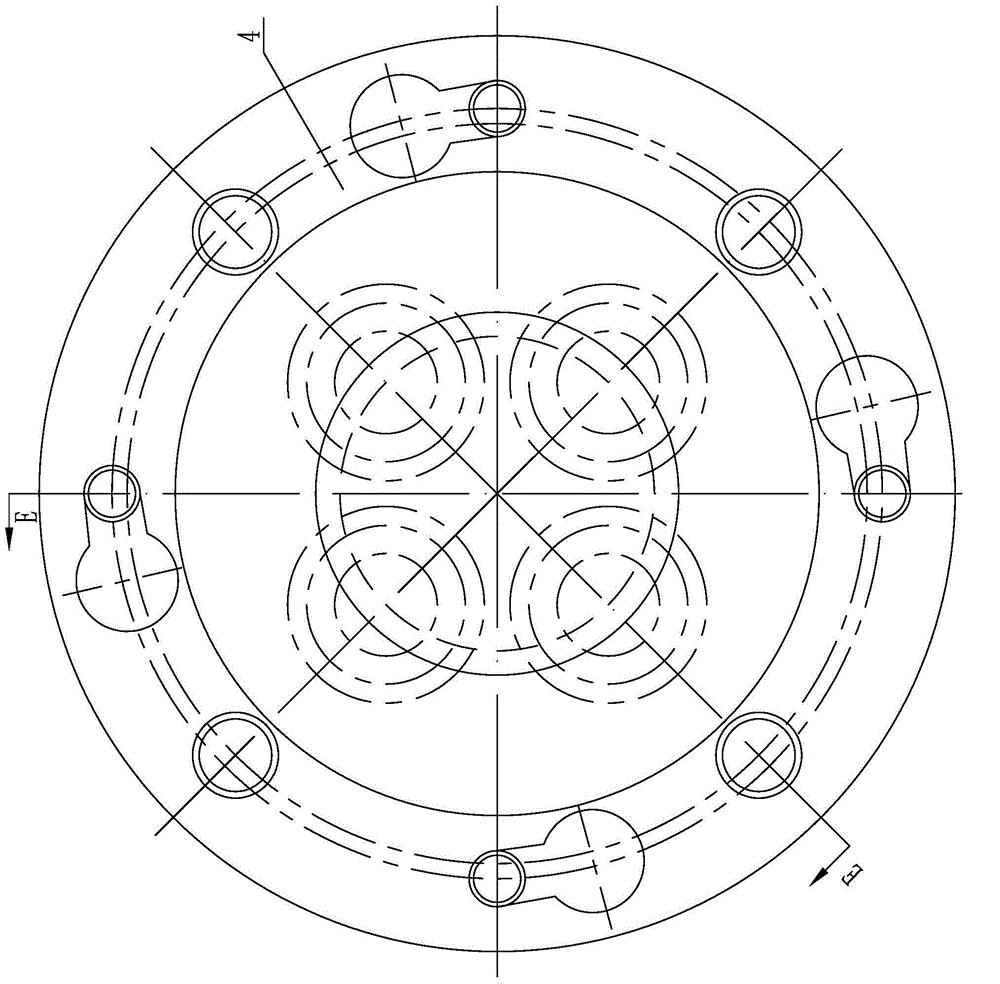

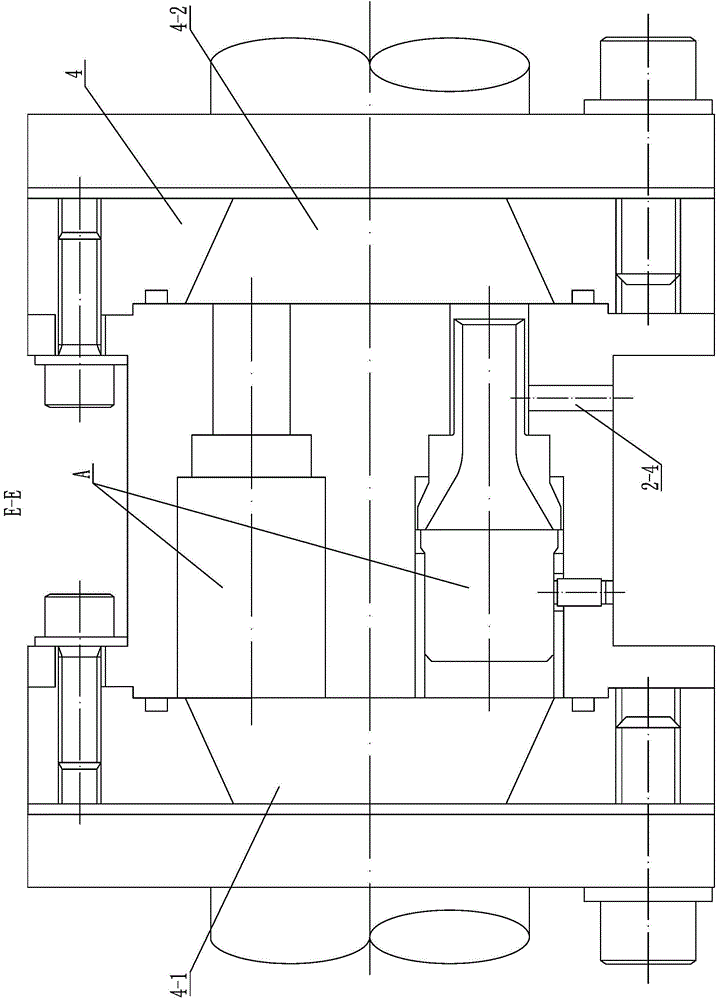

[0012] Specific implementation mode 1: Combination figure 1 with Figure 5 Explain that the gas-liquid or liquid-liquid mixing nanobubble generating device of this embodiment includes a water storage tank 7, a gas-liquid mixing pump 8, a total water inlet pipe 5, and a total water outlet pipe 6. The water storage tank 7 is mixed with the gas and liquid through the water pipe The pump 8 is in communication, and the total water inlet pipe 5 is in communication with the gas-liquid mixing pump 8; it also includes a nano bubble generator A, which includes a first sleeve 1, a second sleeve 2 and a mixing nozzle 3; The inner cavity of the second sleeve 2 includes a straight cavity 2-1, a cylindrical cavity 2-2 and a cone cavity 2-3, and the cylindrical cavity 2-2 is arranged between the straight cavity 2-1 and the cone cavity 2-3 , The inner cavity of the first sleeve 1 includes a first cavity 1-1 and a second cavity 1-2, the first cavity 1-1 is sleeved on the outer wall surface of the...

specific Embodiment approach 2

[0013] Specific implementation manner two: combination figure 1 It is explained that the fluid mixing and stirring section 3-2 of this embodiment is a fluid mixing and stirring section with a constant cross-section inner cavity or a cross-sectional area gradually expanding from the cylindrical cavity 2-2 to the conical cavity 2-3.

[0014] The beneficial effect of this embodiment is that the gas or liquid can be quickly cut into nanometers, a large amount of gas or liquid with a diameter of nanometers can be injected into the liquid, and the concentration of the gas or liquid can be instantly increased, and it can be sealed for a long time. In the liquid. Others are the same as the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 It is explained that the fluid mixing and stirring section 3-2 of this embodiment is a cylindrical cavity, the diameter D1 of the fluid mixing and stirring section 3-2 is 1mm-1000mm, the diameter d of the fluid channel 2-4 is 1mm-1000mm, and the tapered section 3-2 The diameter D2 of the large diameter end of 1 is 1mm-2000mm, the diameter K of the large diameter end of the tapered cavity 2-3 is 1mm-2000mm, the second cavity 1-2 is a cylindrical cavity, and the diameter of the second cavity 1-2 D3 is 1mm-2000mm.

[0016] The beneficial effect of this embodiment is that the gas or liquid can be quickly cut into nanometers, a large amount of gas or liquid with a diameter of nanometers can be injected into the liquid, and the concentration of the gas or liquid can be instantly increased, and it can be sealed for a long time. In the liquid. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com