3D printing robot capable of freely moving

A 3D printing and robotics technology, applied in the field of mobile robots, can solve the problems of high printing efficiency, limited printing size, low cost, etc., and achieve the effect of fast printing speed, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

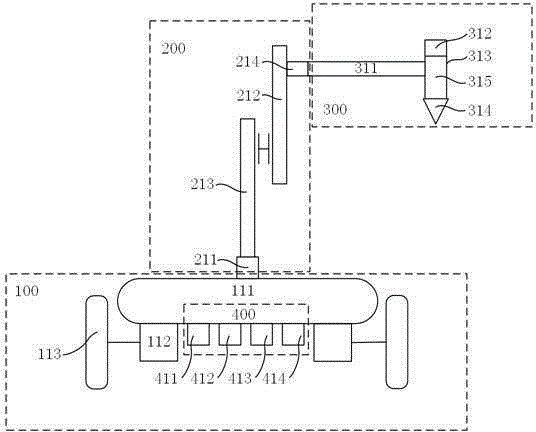

[0038] see figure 1 and Figure 10 , a 3D printing robot that can move freely, including an omnidirectional mobile platform mechanism 100, a Z-axis lifting mechanism 200, a 3D printing mechanism 300, a feedback / communication / control circuit 400, and the omnidirectional mobile platform mechanism 100 is fixedly connected to the Z-axis lifting mechanism. The mechanism 200 is fixedly connected to the 3D printing mechanism 300 on the Z-axis lifting mechanism 200, and at the same time, a feedback / communication / control circuit 400 is installed on the omnidirectional mobile platform mechanism 100;

[0039]The omnidirectional mobile platform mechanism 100 includes a mobile platform base 111, a motion motor 112, and a motion wheel 113. The motion motor 112 is installed on the mobile platform base 111 and the output end is connected with a motion wheel 113 to form a wheel motion mechanism.

[0040] The Z-axis lifting mechanism 200 includes a lifting motor 211, a lifting and movin...

Embodiment 2

[0045] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

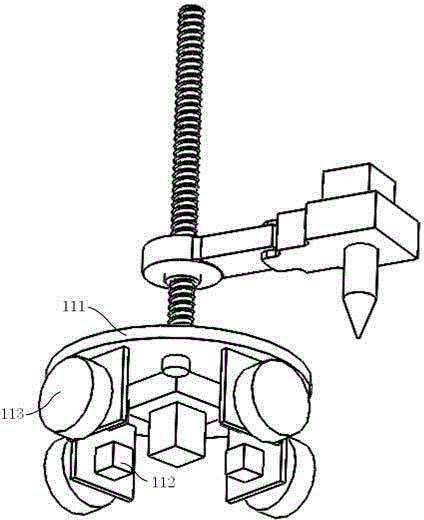

[0046] see figure 2 , in this embodiment, the omni-directional mobile platform mechanism 100 is arranged symmetrically according to the center of the mobile platform base 111 with 4 omnidirectional drive wheel motion mechanisms that are 90 degrees to each other, and the rotational speed of the 4 motion wheels 113 is controlled by the motion motor 112 Realize the all-round movement of the all-round mobile platform.

Embodiment 3

[0048] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

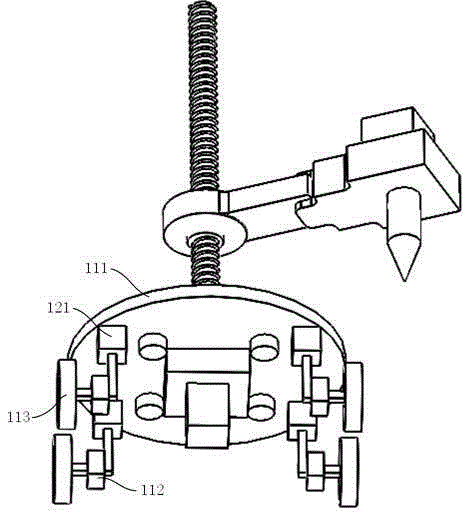

[0049] see image 3 , in this embodiment, the omni-directional mobile platform mechanism 100 should also include the steering motor 121 that can realize the steering of the moving wheel 113, and the omni-directional mobile platform mechanism 100 is arranged in a rectangular shape according to the mobile platform base 111. 4 can simultaneously realize the driving And the wheel kinematic mechanism of turning, realizes the omnidirectional movement of omnidirectional mobile platform by steering motor 121 and kinematic motor 112 to control the steering and the rotating speed of 4 kinematic wheels 113.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com