Motor direct-driving bogie

A bogie and direct drive technology, applied in the field of bogies, can solve the problems of affecting the curve passing performance of the train, the increase of maintenance cycle costs, and the increase of the wheelbase of the bogie, so as to improve the energy use effect, reduce the weight, and reduce the stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

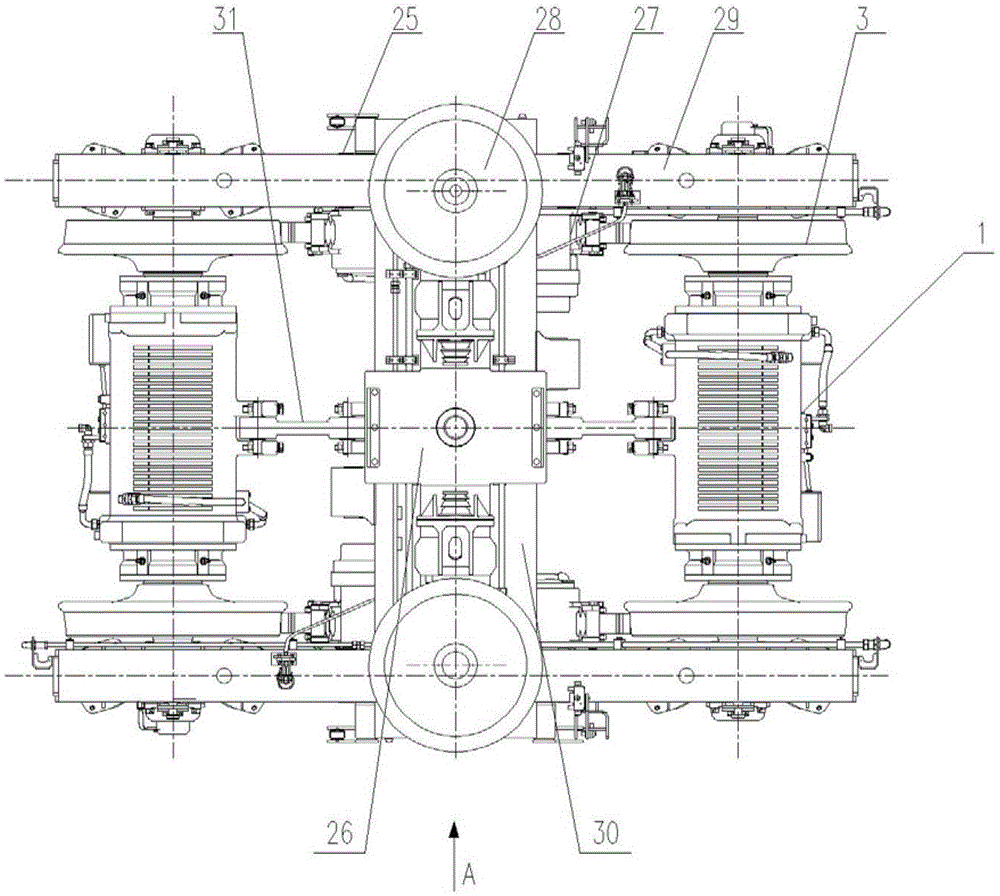

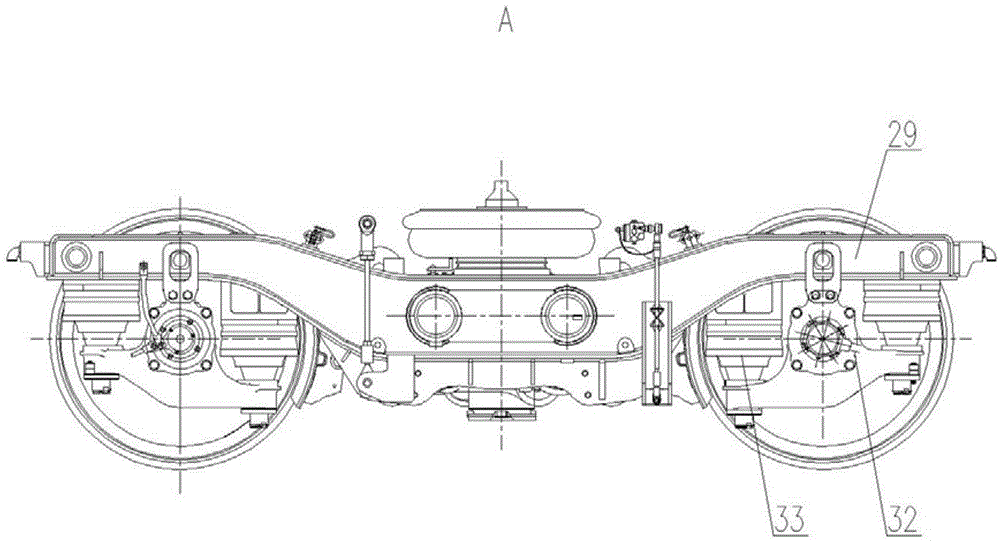

[0026] like figure 1 and figure 2 As shown, a rail vehicle motor direct drive bogie includes a frame 25, a traction device 26 arranged on the frame 25, a foundation braking device 27, a secondary spring 28 and a wheel set drive system.

[0027] The frame 25 is an H-shaped welded frame, including two side beams 29 and two cross beams 30. The two cross beams 30 are welded in the middle of the side beams 29 to connect the two side beams 29. 29 middle parts are provided with secondary spring 28, and secondary spring 28 adopts an air spring.

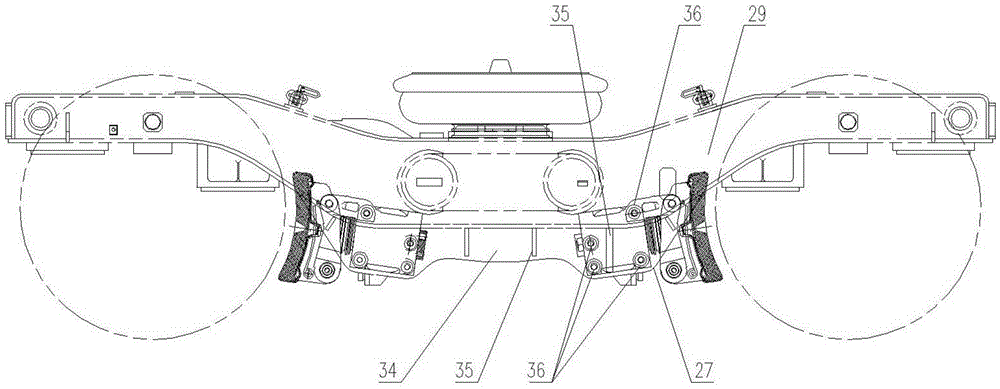

[0028] like image 3 As shown, a supporting plate 34 is fixed at the bottom of the side beam 29, the foundation braking device 27 is fixed on the supporting plate 34 and the side beam 29, and the supporting plate 34 is welded and fixed on the bottom of the side beam 29, specifically welded on the side beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com