Coupling device for frame and bodywork

A car body and frame technology, which is applied to the field of rail car bogie frame and car body connecting device, can solve the problems of potential safety hazards, economic losses, large stress on hydraulic shock absorbers, etc. The effect of improving the economic efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

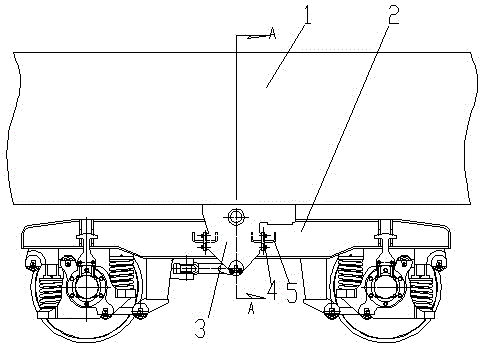

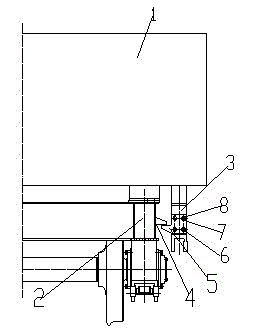

[0012] given in the present invention figure 1 , figure 2 In the embodiment, the continuous work hanging device is composed of a car body 1, a frame 2, a car body traction seat 3, a hanging plate 4, and a hook plate 5. The hanging plate 4 is welded on the bogie frame 2, and the middle part of the side wall of the hanging plate 4 is provided with a hook; , is installed and fixed on the traction seat 3, and the hook on the hook plate 5 is combined with the hook on the hook plate 4 to form the connecting device on the railcar bogie frame 2 and the car body 1.

[0013] When the rail car is in the ready state, the connecting device connects the car body 1, the car body fifth wheel 3 and the bogie frame 2 together. The car body 1 is hoisted or jacked up, the traction seat 3 rises with the car body 1, and the hook on the hook plate 5 rises together with the car body traction seat 3 until the hook on the link plate 4 is combined with the hook on the hook plate 5 Together, the hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com