Method for preparing nanometer titania

A technology of nano-titanium dioxide and preparation steps, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of difficulty in titanium dioxide powder, and achieve the effect of loose preparation conditions

Inactive Publication Date: 2015-04-22

南京乐汉东智能设备有限公司 +1

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Because super-thin materials often involve nano-titanium dioxide, the conditions for preparing nano-titanium dioxide are relatively harsh, which makes it difficult for industrial mass production of nano-level titanium dioxide powder.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

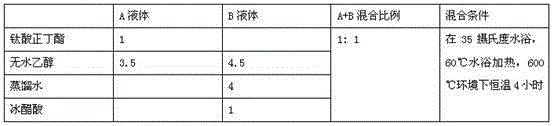

Embodiment 2

[0020]

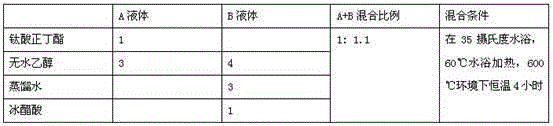

Embodiment 3

[0022]

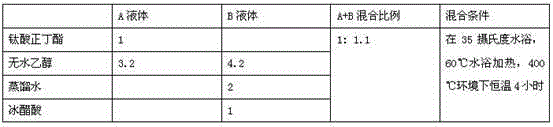

Embodiment 4

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preparing nanometer titania. The method comprises the following steps: uniformly mixing tetrabutyl titanate and absolute ethyl alcohol according to a volume ratio of 1:(2.5-3.5), thereby obtaining a solution A; mixing and stirring glacial acetic acid, absolute ethyl alcohol and distilled water according to a volume ratio of 1:(3.5-4.5):(1.1-4), adding hydrochloric acid, regulating the pH value to be less than or equal to 3.5, and preparing a liquid B; adding the solution A and the liquid B into a water bath at the temperature of 25-35 DEG C according to a volume ratio of 1:1.1, pouring the solution A into the liquid B while stirring, continuously stirring the obtained mixed solution for at least half an hour, heating in a water bath at the temperature of 40-60 DEG C, thereby obtaining white gel after 2 hours; airing the gel in a fuming cupboard, adding the gel into a muffle furnace, preserving the temperature for 2-4 hours in an environment of 400-600 DEG C, thus obtaining a solid, grinding, thereby obtaining the powder, wherein the powder refers to the nanometer titania. The method has the advantages that the preparation conditions are wide, and the method is easily applied to industrial production.

Description

technical field [0001] The invention relates to the technical field of chemical industry, in particular to a preparation method of nano titanium dioxide. Background technique [0002] Because super-thin materials often involve nano-titanium dioxide, but the current conditions for preparing nano-titanium dioxide are relatively harsh, making it difficult to produce nano-scale titanium dioxide powder in large quantities in industry. Contents of the invention [0003] The purpose of the present invention is to provide a method for preparing nanometer titanium dioxide with relatively relaxed conditions. [0004] The solution of the present invention is this: [0005] A preparation method of nano-titanium dioxide, comprising the steps of: [0006] (1) Preparation steps of liquid A: put n-butyl titanate and absolute ethanol at a volume ratio of 1:2.5-3.5, pour n-butyl titanate into absolute ethanol, and stir vigorously with a magnetic stirrer for 9- 15min, mix well, and prepa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G23/053

Inventor 闫共芹罗玉军张永军刘建华陈志

Owner 南京乐汉东智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com