Nanometer layered metal compound electrode material grown on conductive substrate and preparation and application of nanometer layered metal compound electrode material

A metal compound, conductive substrate technology, applied in the field of electrochemical materials, can solve the problems of difficult to achieve large-scale preparation of nano-material products, complex preparation process conditions, high equipment conditions, etc., to achieve excellent electrochemical performance, controllable line height , The effect of process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

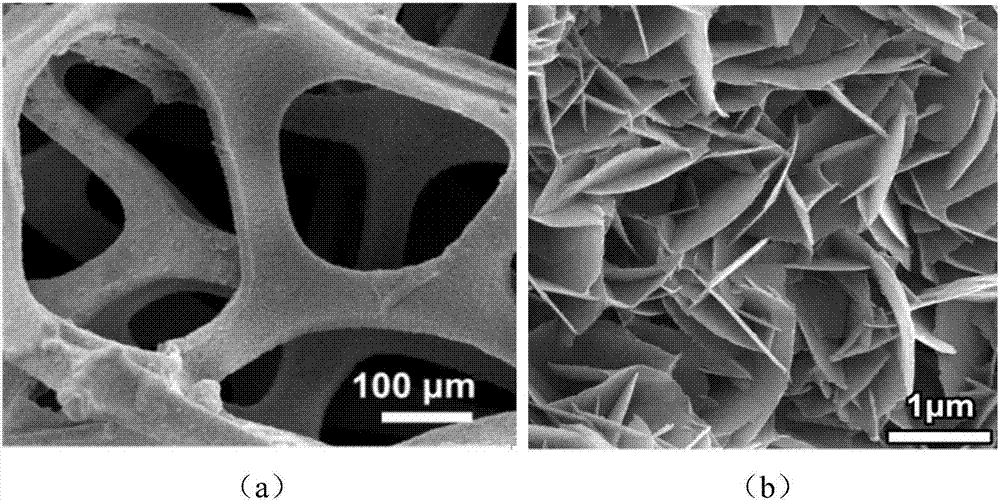

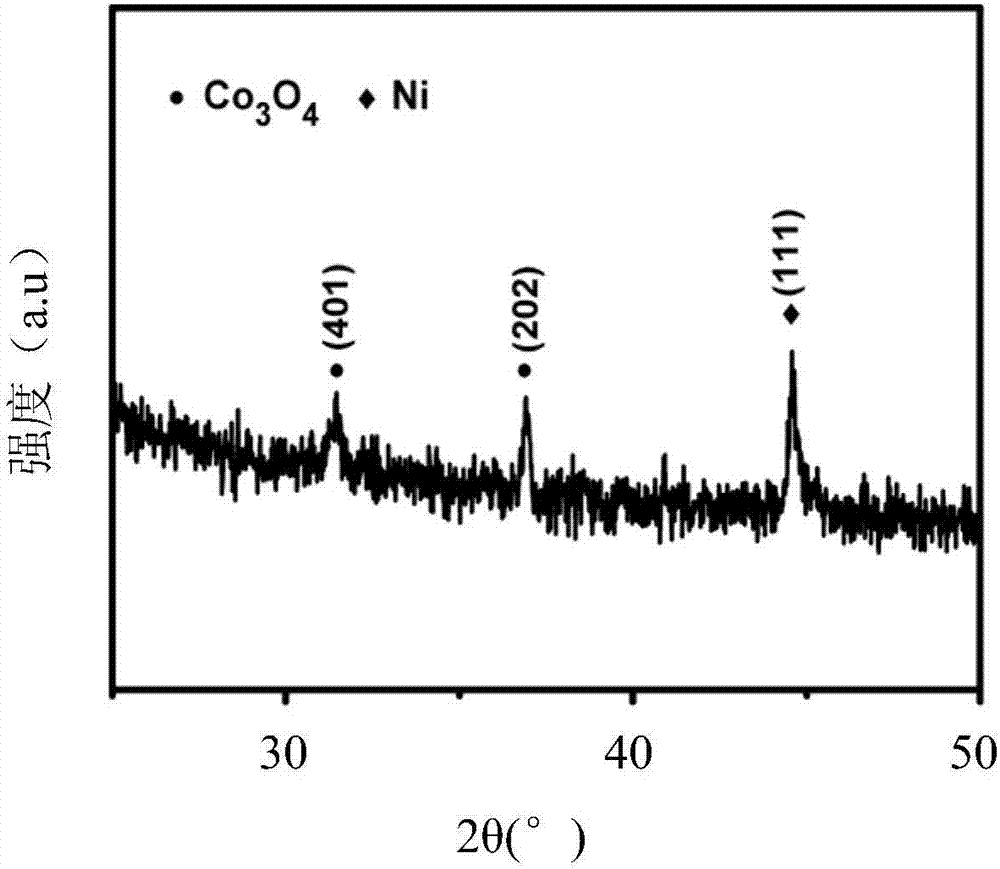

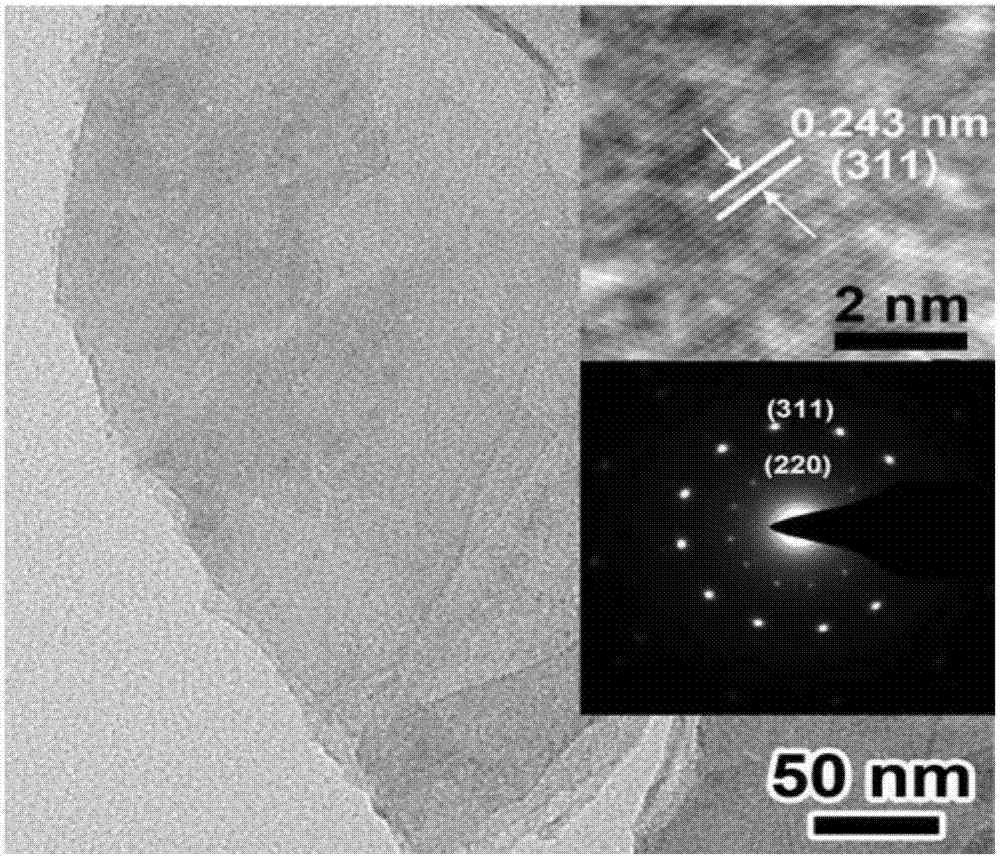

[0036] A preparation method for growing a nano-layered metal compound electrode material on a conductive substrate, comprising the following steps:

[0037] (1) Cut the nickel foam into 4cm×2cm, soak it in alcohol and acetone ultrasonically for 30min in turn, wash it with deionized water, and dry it at 60°C for later use;

[0038] (2) Prepare 1mmol / L CoCl with cobalt chloride and water 2 Precursor solution, stirred for 30 minutes to make the precursor solution evenly mixed;

[0039] (3) Fill the above-mentioned precursor solution of about 80% volume in the reaction kettle liner of polytetrafluoroethylene material; Then place the foamed nickel through pretreatment in the reaction kettle liner, then seal with a stainless steel reaction kettle, Hydrothermal reaction at 100°C for 10 hours. After the reaction is completed, the hydrothermal kettle is naturally cooled, and the nickel foam is taken out, washed several times with ethanol and deionized water, and dried at 60°C for 12 h...

Embodiment 2

[0045] A preparation method for growing a nano-layered metal compound electrode material on a conductive substrate, comprising the following steps:

[0046] (1) Cut the nickel foil into 4cm×2cm, soak it in alcohol and acetone ultrasonically for 30 minutes, wash it with deionized water, and dry it at 80°C for later use;

[0047] (2) Prepare 1mmol / L NiCl with nickel chloride and water 2 Precursor solution, stirred for 30 minutes to make the precursor solution evenly mixed;

[0048] (3) Fill the above-mentioned precursor solution of about 90% volume in the reaction kettle liner of polytetrafluoroethylene material; Then place the pretreated nickel foil in the reaction kettle liner, and then seal it with a stainless steel reaction kettle, Hydrothermal reaction at 100°C for 10 hours, after the reaction was completed, the hydrothermal kettle was cooled naturally, the nickel foil was taken out, washed several times with ethanol and deionized water, and dried at 100°C for 6 hours to obt...

Embodiment 3

[0052] A preparation method for growing a nano-layered metal compound electrode material on a conductive substrate, comprising the following steps:

[0053] (1) Cut the nickel foam into 4cm×2cm, soak it in alcohol and acetone ultrasonically for 30 minutes, wash it with deionized water, and dry it at 100°C for later use;

[0054] (2) Prepare 1mmol / L MnCl with manganese chloride and water 2 Precursor solution, stirred for 30 minutes to make the precursor solution evenly mixed;

[0055] (3) Fill the above-mentioned precursor solution of about 50% volume in the reaction kettle liner of polytetrafluoroethylene material; Then place the foamed nickel through pretreatment in the reaction kettle liner, then seal with a stainless steel reaction kettle, Put it in 80°C hydrothermal reaction for 20 hours, after the reaction is completed, the hydrothermal kettle is naturally cooled, take out the foamed nickel, wash it with ethanol and deionized water several times, and dry it at 60°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com