A preparation method of super hydrolysis-resistant high-stripping elastic nubuck leather

A nubuck leather with high peeling technology, which is applied in the direction of roughening, textile and papermaking, fabric surface trimming, etc. It can solve the problems of low peel strength, low quality, good color development, etc., and achieve crispness and dimensional stability Good, easy to control production and processing, fine and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

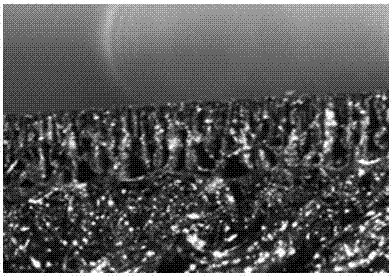

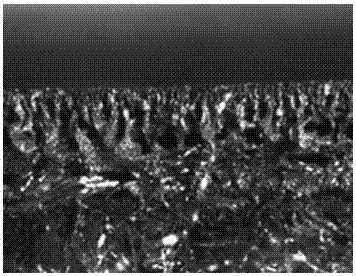

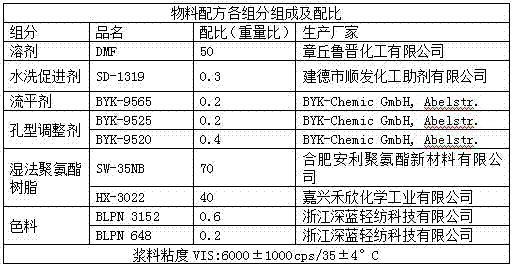

[0033] Preparation of wet bass: use a weight of 220g / m 2 , the width is 1.6m, and the black imitation cotton wool of thickness 0.8mm is used as the base cloth of wet method bass, and the physical properties of the base cloth of the present invention are compared with other base cloths at present and see Table 5; The cloth is placed on the cloth rack and sent to the wet-laid bass production line, which is sequentially processed through the pre-condensation tank, ironing roller, coating machine, main condensation tank, washing tank, oven, and cooling roller to make nubuck wet-laid bass, bass Roll up and set aside. Among them, the coating slurry formula of the wet process base is shown in Table 1. During the production and processing of the wet process base, the process parameters of each part of the wet process production line are set as follows: the DMF concentration in the pre-coagulation tank is 30%, the production speed 8m / min, production line tension 0.08MPa, cutter head g...

Embodiment 2

[0037] Preparation of wet bass: use a weight of 240g / m 2 , with a width of 1.7m and a thickness of 0.9mm, the pink imitation cotton wool is used as the base cloth of the wet process bass. The physical properties of the base cloth of the present invention are compared with other base cloths at present. See Table 5; The cloth is placed on the cloth rack and sent to the wet-laid bass production line, which is sequentially processed through the pre-condensation tank, ironing roller, coating machine, main condensation tank, washing tank, oven, and cooling roller to make nubuck wet-laid bass, bass Roll up and set aside. Among them, the coating slurry formula of the wet process base is shown in Table 2. During the production and processing of the wet process base, the process parameters of each part of the wet process production line are set as follows: the DMF concentration in the pre-coagulation tank is 40%, the production speed 12m / min, production line tension 0.12MPa, cutter hea...

Embodiment 3

[0041] Preparation of wet bass: use a weight of 230g / m 2 , with a width of 1.65m and a thickness of 0.85mm, the blue imitation cotton wool is used as the base cloth of the wet process bass. The physical properties of the base cloth of the present invention are compared with other base cloths at present in Table 5; the smooth surface of the base cloth is selected as the coating surface. The base fabric is placed on the cloth rack and sent to the wet-laid bass production line, which is sequentially processed by the pre-condensation tank, ironing roller, coating machine, main condensation tank, washing tank, oven, and cooling roller to make nubuck wet-laid bass. Bass rolls back up. Among them, the coating slurry formula of the wet process base is shown in Table 3. During the production and processing of the wet process, the process parameters of each part of the wet process production line are set as follows: the DMF concentration in the pre-coagulation tank is 35%, the productio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com