Method for producing ultra-thin lightweight leather for sports and leisure shoes

A manufacturing method and lightweight technology, applied in chemical instruments and methods, footwear, textiles and papermaking, etc., can solve the development trend that cannot conform to beauty, fashion and light weight, affect lightness and comfort, and shape shoes. It can achieve the effect of good flexibility, good flatness and good film-forming elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment carries out according to the following steps:

[0033] 1. Select the ultra-thin composite cloth base with a thickness of 0.4mm and a mass ratio of fiber components (nylon: polyester = 50:50) as the base material;

[0034] The ultra-thin composite fabric base is processed by woven fabric and non-woven fabric (both fiber components are nylon and polyester with a mass ratio of 50:50) by laying and needling bonding.

[0035] 2. Using wet-process synthetic leather production equipment, the ultra-thin composite cloth base is impregnated and coated with wet-process to make wet-process semi-finished products;

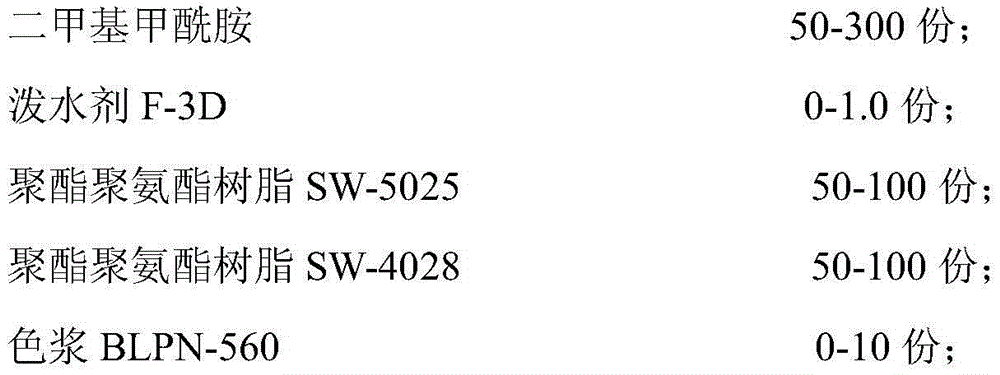

[0036] Polyurethane impregnation slurry is obtained by the following raw materials in parts by mass:

[0037]

[0038] The preparation method of polyurethane impregnation slurry is: add 250 parts of DMF and 0.8 parts of water repellent F-3D to the wet batching kettle in sequence, and stir for 10 minutes at normal temperature and pressure, and t...

Embodiment 2

[0060] The present embodiment carries out according to the following steps:

[0061] 1. Select the ultra-thin composite cloth base with a thickness of 0.35mm and a fiber composition mass ratio (nylon: polyester = 40:60) as the base material; the ultra-thin composite cloth base is made of woven fabric and non-woven fabric (the fiber composition of both All are nylon and polyester with a mass ratio of 40:60) processed by laying and needle-punching.

[0062] 2. Using wet-process synthetic leather production equipment, the ultra-thin composite cloth base is impregnated and coated with wet-process to make wet-process semi-finished products;

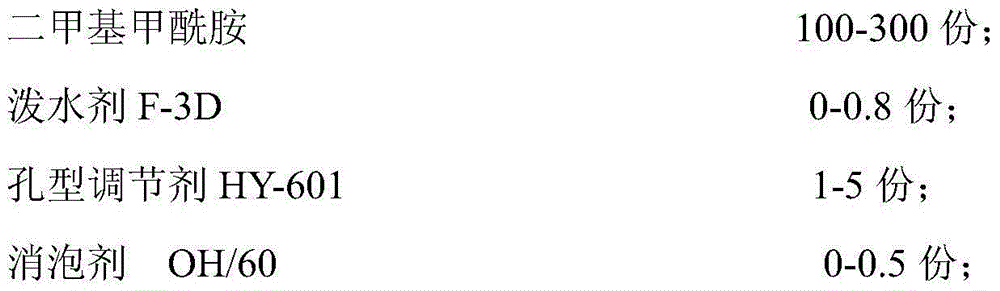

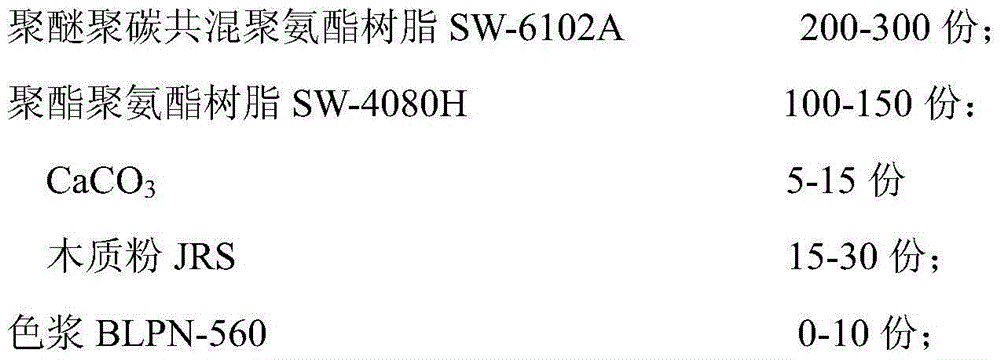

[0063] Polyurethane impregnation slurry is obtained by the following raw materials in parts by mass:

[0064]

[0065]

[0066] The preparation method of polyurethane impregnation slurry is: add 220 parts of DMF and 0.6 parts of water repellent F-3D to the wet batching kettle in sequence, and stir for 10 minutes at normal temperature an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com