Automatic water level control weir gate

A weir gate and water level technology, applied in water conservancy projects, barrage/weirs, sea area engineering, etc., can solve problems such as poor structure, easy failure, difficult installation and disassembly, etc., and achieve the effect of simple structure and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

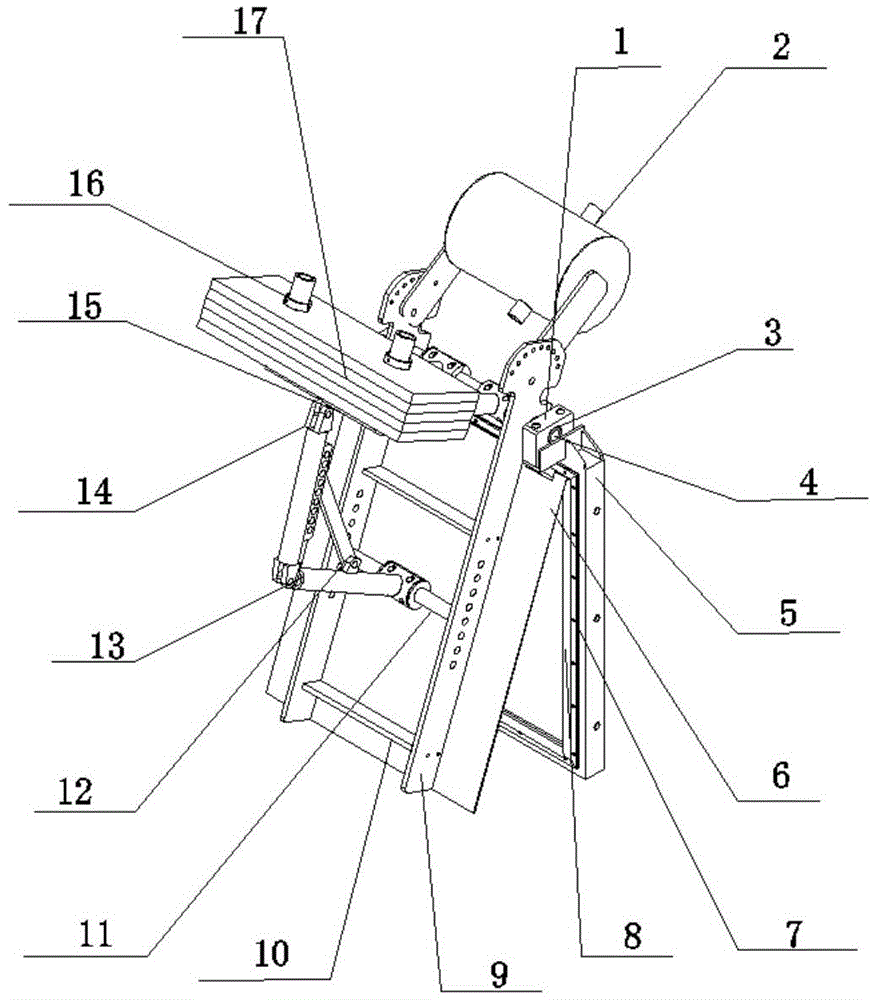

[0014] A water level automatic control weir gate, comprising a water retaining plate 6, a water retaining plate frame 9, a rotating arm assembly, a balance arm 15, a connecting rod assembly, a central arm shaft 11, a counterweight 17, a fixed frame 5, The balance water cylinder 2, the balance force arm 15 is connected on the center force arm shaft 11 by the connecting rod assembly connected in series, the center force arm shaft 11 is installed on the water retaining plate frame 9, and the water retaining plate 6 is fixed on the water retaining plate frame 9, The back reinforcement rib 10 is also inherent on the fender frame 9, and the fender frame 9 manually adjusts the angle of the balance arm 15 and the fender 6 through the connecting rod assembly, thereby changing the adjustment of the angle of the fender 6 by the impact of the water flow.

[0015] The connecting rod assembly includes a balance arm connecting rod 14 , a central moment arm connecting rod 13 and a fixed angle ...

Embodiment 2

[0019] A water level automatic control weir gate, comprising a water retaining plate 6, a water retaining plate frame 9, a rotating arm assembly, a balance arm 15, a connecting rod assembly, a central arm shaft 11, a counterweight 17, a fixed frame 5, The balance water cylinder 2, the balance force arm 15 is connected on the center force arm shaft 11 by the connecting rod assembly connected in series, the center force arm shaft 11 is installed on the water retaining plate frame 9, and the water retaining plate 6 is fixed on the water retaining plate frame 9, The back reinforcement rib 10 is also inherent on the fender frame 9. By adjusting the position of the central moment arm shaft 11 on the fender frame 9, the angle of the balance arm 15 can be adjusted, thereby changing the impact of the water flow on the angle of the fender 6. Adjustment.

[0020] The connecting rod assembly includes a balance arm connecting rod 14 , a central moment arm connecting rod 13 and a fixed angl...

Embodiment 3

[0024] A water level automatic control weir gate, comprising a water retaining plate 6, a water retaining plate frame 9, a rotating arm assembly, a balance arm 15, a connecting rod assembly, a central arm shaft 11, a counterweight 17, a fixed frame 5, The balance water cylinder 2, the balance force arm 15 is connected on the center force arm shaft 11 by the connecting rod assembly connected in series, the center force arm shaft 11 is installed on the water retaining plate frame 9, and the water retaining plate 6 is fixed on the water retaining plate frame 9, The back reinforcement rib 10 is also inherent on the water retaining plate frame 9, and the angle at which the water retaining plate 9 needs to be opened is designed according to the upstream water level, and the weight of the counterweight 17 is determined, and the counterweight 17 is fixed on the balance arm by a fastening nut 16 On 15, add water in balance water cylinder 2, add to a certain degree, make counterweight we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com