Construction method of high-rise building glass guardrail

A technology for high-rise buildings and construction methods, which is applied in the directions of buildings, building structures, stepped structures, etc., can solve the problems of difficult to control the accuracy and quality of on-site installation, the standardization of structural parts is not high, and the construction period of the railing system is long. Achieve the effect of easy post-maintenance and disassembly, reasonable design and short construction period on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

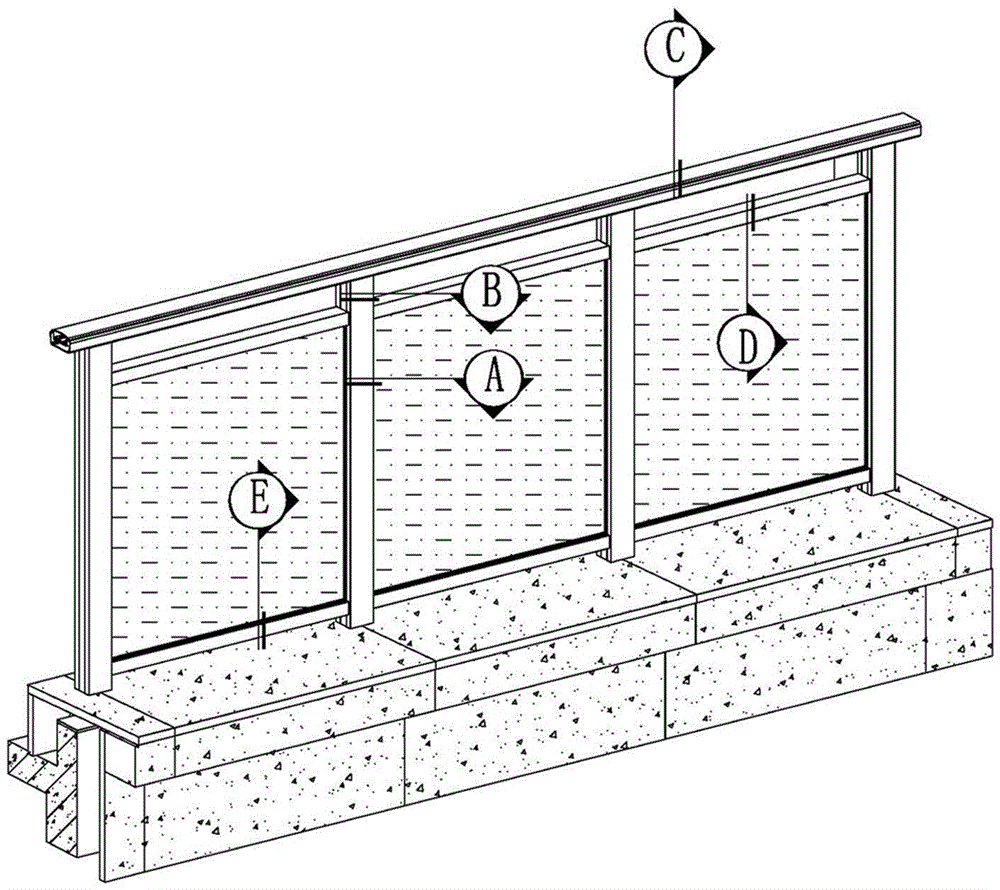

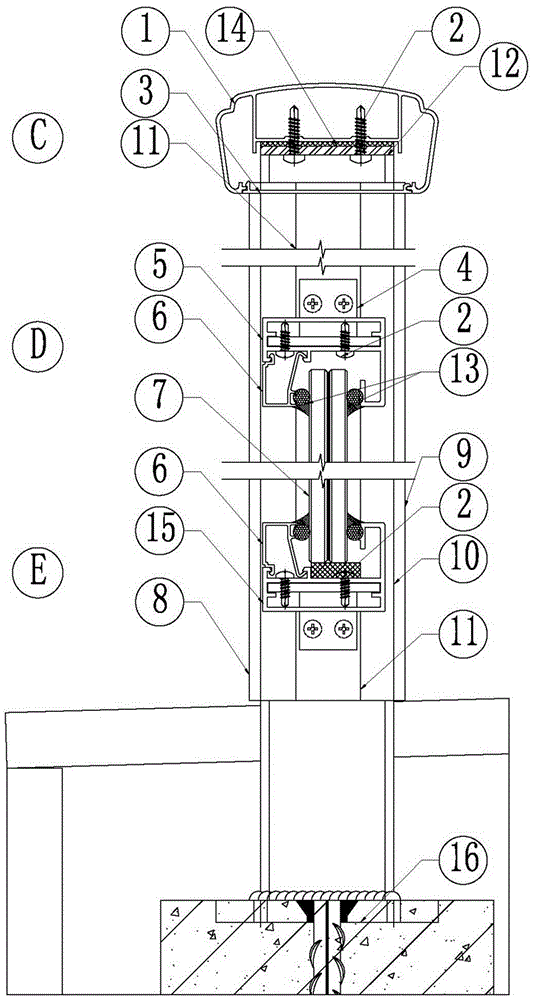

[0035] Such as figure 2 As shown, the high-rise building glass guardrail system of the present invention includes aluminum alloy corner code 4, tempered laminated glass 7, sealant and foam rod 13, self-tapping screw 2 and several pre-embedded lines arranged in the high-rise building structure Structure 16.

[0036] Such as figure 1 , figure 2 As shown, in the high-rise building glass guardrail system of the present invention, a rectangular square steel column 10 is welded on each pre-embedded structural member 16 . A handrail steel plate 12 is welded together at the tops of some connected square steel columns 10 .

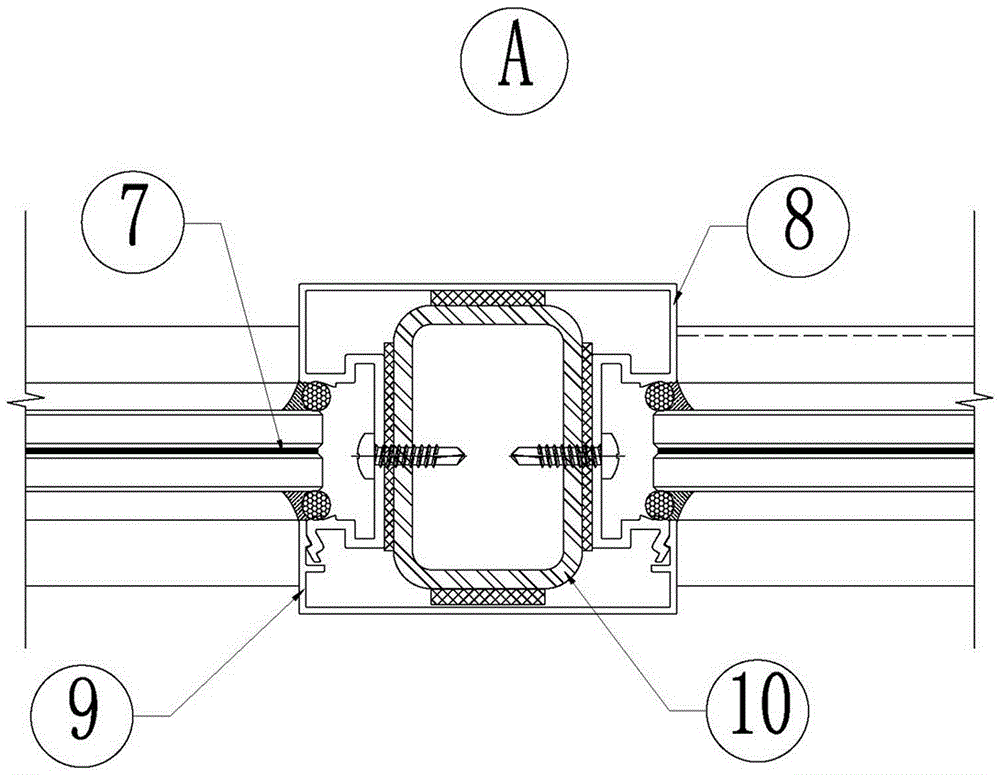

[0037] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the rear cylindrical surface of the square steel column 10 and the cylindrical surfaces on both sides are fastened together to connect the aluminum alloy main component 8 . The aluminum alloy main component 8 is fixed on the left and right sides of the square steel column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com