A method for drilling, completion and stimulation of fishbone-shaped multi-level branched horizontal wells in shale gas reservoirs

A branch well and horizontal well technology, applied in directional drilling, wellbore/well components, earthwork drilling and production, etc., can solve the problems of high cost, water shortage, non-recyclable, etc., and achieve improved recovery and low cost The effect of mining and streamlining equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

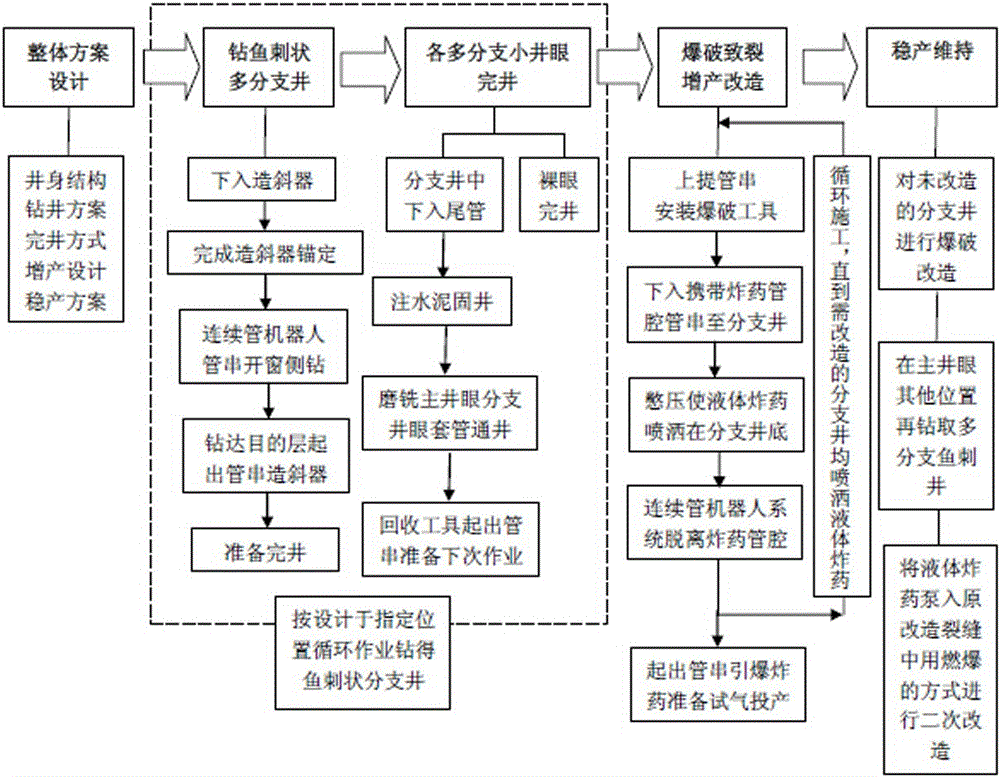

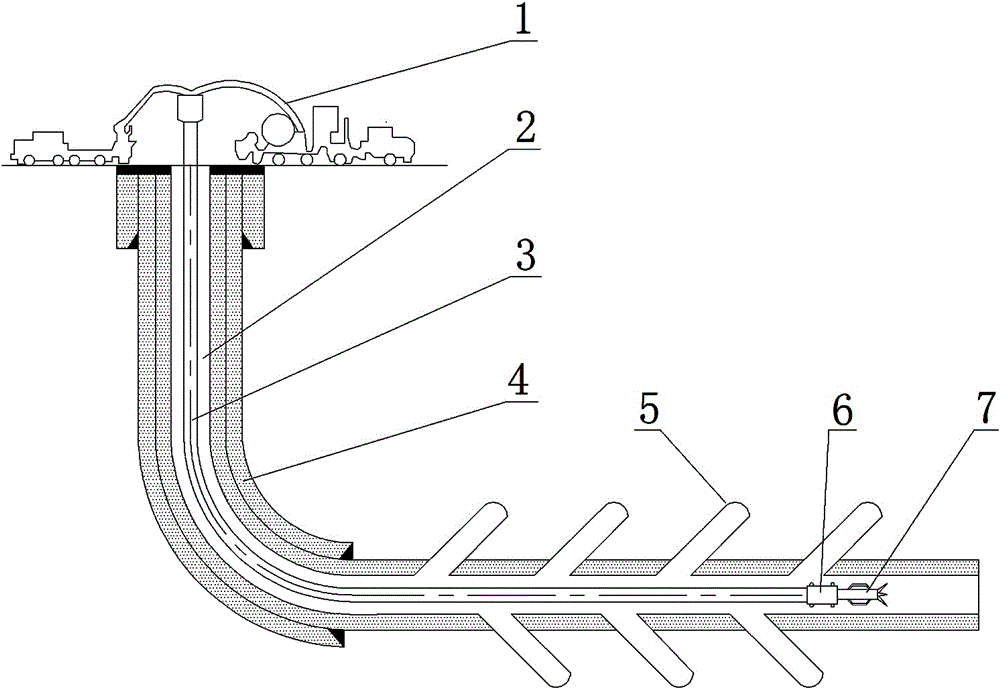

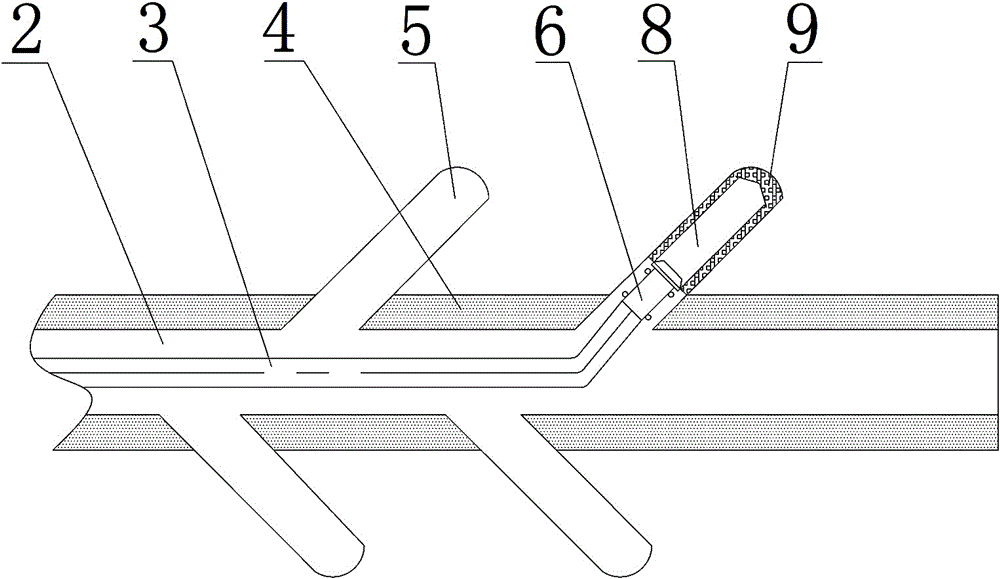

[0029] Such as Figure 1-4 As shown, the coiled tubing 3 used in the present invention for the exploitation of tight shale gas cooperates with the drilling robot 6 to drill multi-branched fishbone wells and use rapid solidification liquid explosives for directional blasting. 2, the coiled tubing 3 and the drilling robot 6 carrying the drilling tool 7 and the deflection tool are drilled in the horizontal section of the horizontal well 2 to drill several fishbone-shaped multi-branch wells, and then the coiled tubing 3 and the drilling robot 6 are used to complete the well Or use low-cost open-hole completion, and then use the coiled tubing 3 to cooperate with the drilling robot 6 to carry the multi-functional fast-curing liquid explosive thin-walled lumen 10 into the bottom of the branch well that need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com