Method for measuring gas well critical liquid-carrying flow

A technology of liquid-carrying flow and gas well, which is used in surveying, earth-moving drilling and production, wellbore/well components, etc., can solve problems such as inability to meet the actual situation in the field, and achieve the effect of reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for measuring the critical liquid-carrying flow rate of a gas well, including the following steps:

[0028] Step 1: Check the well history data of the gas well to obtain the tubing diameter D; take the gas from the gas well, measure the gas composition, and then calculate the relative density γ of the gas relative to the air;

[0029] The relative density γ is obtained by the following method:

[0030] (1) Obtain the gas in the gas well and test its composition;

[0031] (2) Obtain the average relative molecular mass according to the relative molecular mass of each component;

[0032] (3) Calculate the relative density γ from the ratio of the average relative molecular weight to the molecular weight of air.

[0033] Step 2: Measure the bottom hole pressure and temperature T, according to bottomhole pressure and temperature T using an iterative method to calculate the corresponding compression factor ;

[0034] bottom hole press...

Embodiment 2

[0046] Derivation of the present invention: according to the algorithm of Guo and Ghalambor, the kinetic energy factor reflects the flow characteristics of the gas-water two-phase in the tubing. The primary controlling factor for fluid accumulation is downhole conditions. The kinetic energy factor E at the tubing shoe is used as the basis for evaluating the liquid-carrying capacity of gas wells.

[0047]

[0048] (1)

[0049] It can be solved by formula (1):

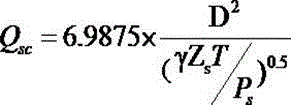

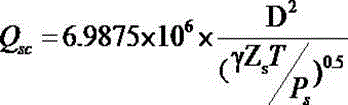

[0050] (2)

[0051] In the formula: ——the flow velocity of the gas at the tubing shoe, m· ;

[0052] ——The density of the gas converted to the tubing shoe, kg· ;

[0053] Q - gas production, · ;

[0054] γ——gas relative density;

[0055] T——downhole temperature, K;

[0056] Ps ——flow pressure at the tubing shoe, MPa;

[0057] D — diameter of oil pipe, m;

[0058] Zs——compressibility factor of ...

Embodiment 3

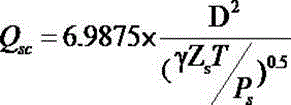

[0073] A well carried out a flow pressure test on October 19, 2013, and its test output was 0.9794×104 / d, the bottomhole flowing pressure is 10.98MPa, the temperature is 378.2K, the relative density of natural gas is 0.6, and the compression factor is 0.93. Substitute the above data into the formula:

[0074]

[0075] The calculated minimum liquid-carrying flow rate of the well is 0.5995×104 / d, less than the actual output 0.9794×104 / d, able to carry liquid production, according to statistics, the daily liquid production of the well is 0.18 , the analysis results are consistent with the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com