Tunnel advance pre-supporting technology used in discrete gravelly soil and broken surrounding rock

A technology for crushing surrounding rock and gravel soil, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of small lead pipe angle, large tunnel overexcavation, and small grouting range, etc., to reduce the amount of grout , Improving structural safety performance and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

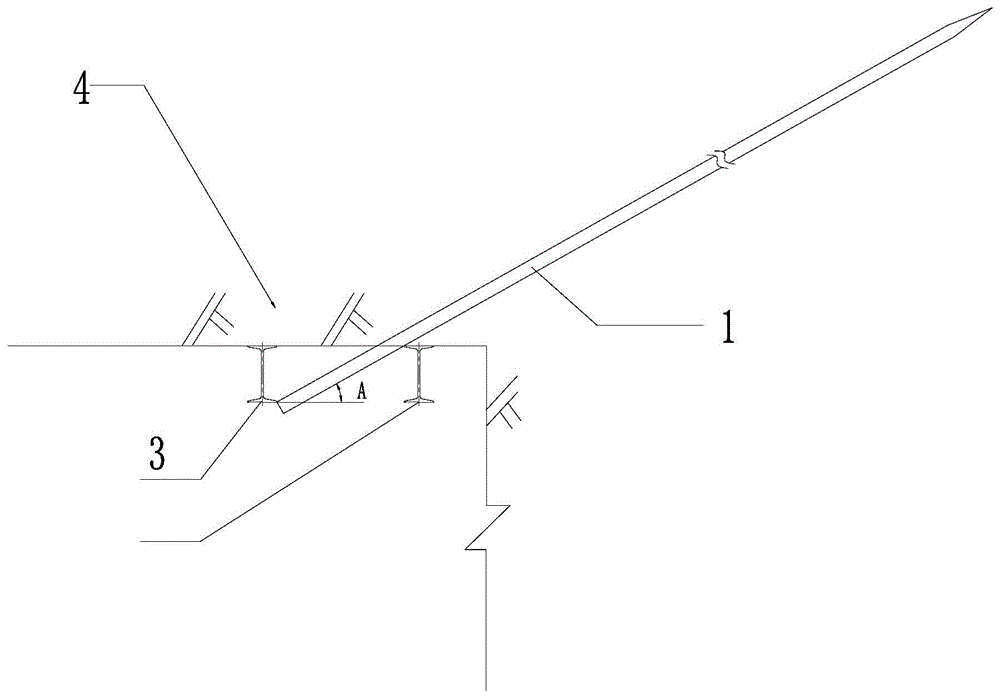

[0025] Specific embodiment: Before the excavation of tunnels with surrounding rocks of grades V to VI, the length of the steel frame 3 is laid in advance along the tunnel excavation contour to a certain range of the rock and soil body 4 outside the tunnel excavation contour line according to the requirements of the design parameters. It is a 300cm to 450cm advance grouting small conduit, and then according to the requirements, the pre-reinforced loose broken rock and soil mass is pre-reinforced through the small conduit and then excavated. After the excavation, the steel support can be constructed in time. Grid steel frame 3, longitudinal connecting bars, steel mesh, sprayed concrete and initial support of radial system. Carry out advanced pre-support for the tunnel first, and then excavate. After the excavation, carry out the initial support in time. The excavation cycle is followed by the initial support. After the excavation and the initial support are completed, the seconda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumferential spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com