Spring tension type sealing piece

An expansion-tightening and sealing technology, applied in the direction of engine sealing, electrical components, electric components, etc., can solve problems such as poor sealing effect, and achieve the effect of not easy to loosen and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

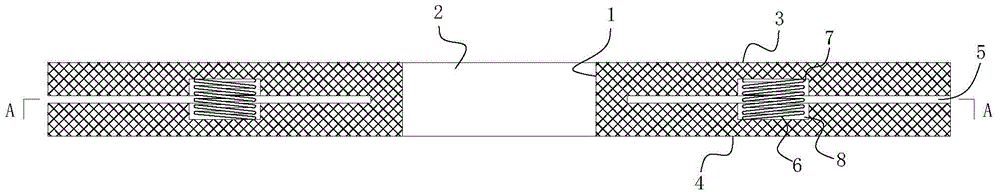

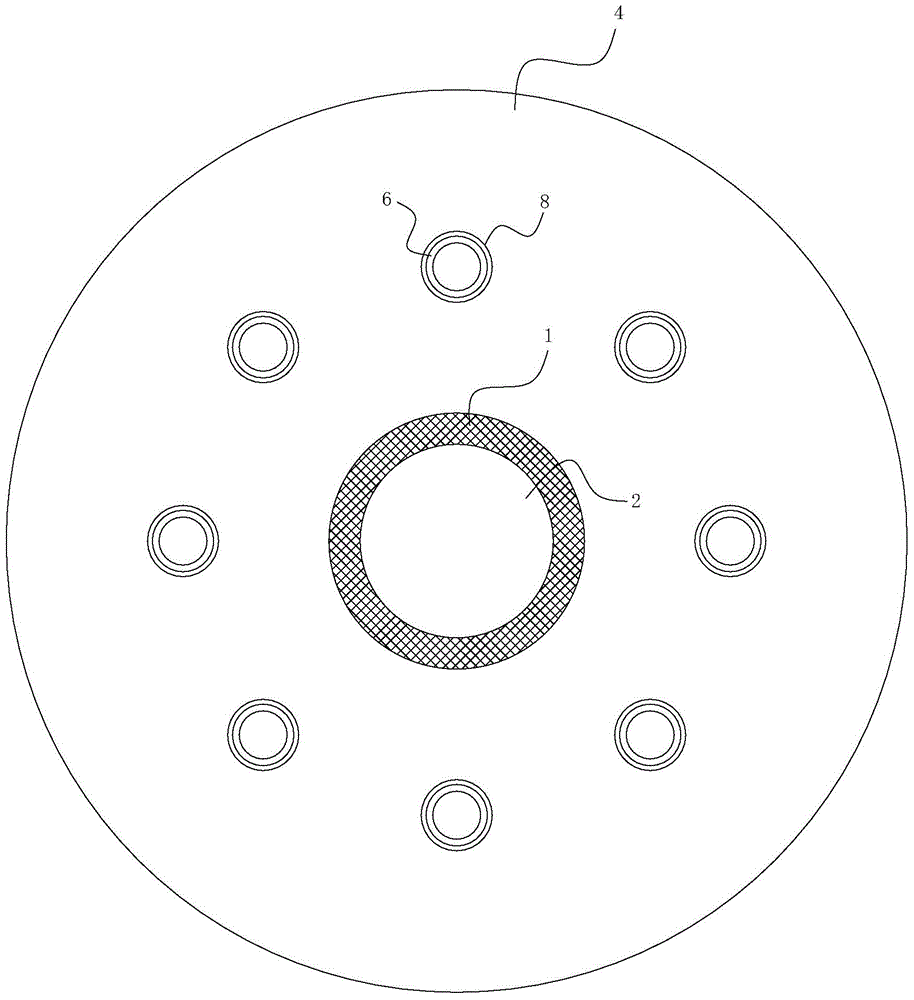

[0013] See Figure 1-Figure 2 , A spring-expandable seal, comprising a cylindrical body 1 having an axial through hole 2 in the center of the cylindrical body 1. The two ends of the cylindrical body 1 extend outward to form an upper sealing flange portion 3 and a lower sealing flange portion 4. There is a circumferential gap 5 between the upper sealing flange portion 3 and the lower sealing flange portion 4. The columnar body 1, the upper sealing flange part 3 and the lower sealing flange part 4 are integrally constructed and are processed by neoprene rubber, which is resistant to high temperature and aging.

[0014] A plurality of upper slot holes 7 evenly distributed around the central circumference of the cylindrical body 1 are provided on the lower surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com