A dual-machine rapid cooling low-temperature refrigeration system and method

A low-temperature refrigeration system and refrigeration method technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of slow cooling rate and deviation from operating efficiency, and achieve the effect of ensuring normal operation and stable long-term operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

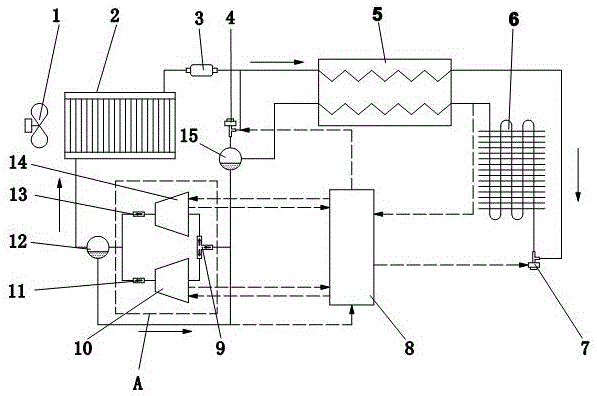

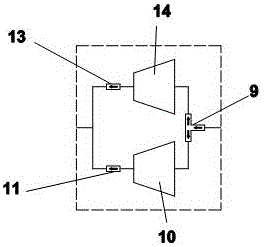

[0030] like figure 1 As shown, a dual-machine rapid cooling low-temperature refrigeration system includes a compressor unit connected by pipelines to form a refrigerant circulation path, an oil separator unit 12, an air-cooled condenser unit 2 with a fan 1, a dryer unit 3, Regenerator unit 5, throttling unit 7, evaporator unit 6, gas-liquid separator unit 15, also includes regulating valve 4, control unit 8, such as figure 2As shown, the compressor unit includes a first compressor 10 and a second compressor 14 connected in parallel, and the input ends of the first compressor 10 and the second compressor 14 are connected to a gas-liquid separator unit 15 through a distributor 9 , the output ports of the first compressor 10 and the second compressor 14 are respectively connected to the oil separator unit 12 through the first one-way valve 11 and the second one-way valve 13, and the inlet of the distributor 9 is also separated from the oil The oil return port of the device unit...

Embodiment 2

[0035] A kind of dual-machine rapid cooling low-temperature refrigeration method based on the above-mentioned system, comprising steps:

[0036] Step 1. Turn on the first compressor 10 and the second compressor 14. The throttling unit 7 is set for the corresponding opening degree under high temperature conditions. The control unit 8 is based on the pressure of the refrigerant at the exhaust end of the compressor unit 1. Adjust the opening of the temperature regulating valve 4 to ensure that the exhaust pressure and temperature of the compressor unit do not exceed the set maximum exhaust pressure and temperature values, so as to realize rapid cooling under high temperature conditions. The high temperature conditions refer to when the evaporator The working condition of the system when the temperature at the outlet of unit 6 is greater than the preset working condition temperature upper limit;

[0037] Step 2. When the temperature of the refrigerant at the outlet of the evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com